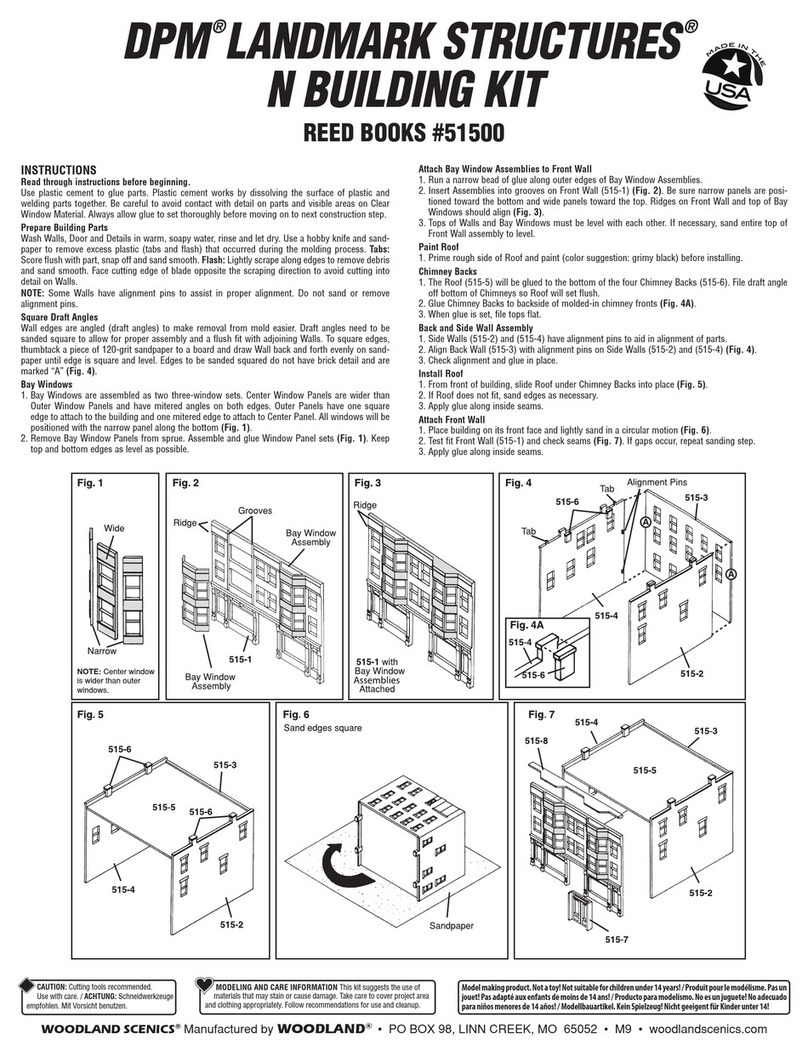

One Piece Chimney Or No Chimney (RP3, RP4, RP5, RP6, RP10, RP11 and RP12)

If your building has separate chimneys, glue square .080 x .080 inch styrene plastic roof support

strips to backs of walls prior to installing roof. Cut roof support strips to lengths that are shorter than

lengths of walls (Fig. 7). If the walls in your kit are different heights, be sure strips are glued so that

roof will be below top of lowest wall. As a general rule you will glue strip about 1/8" down from top

of lowest wall (usually the back wall) and about 1/4" down from top of mid-height walls (usually side

walls). Glue strips on front wall so they are even with strips on other walls. The distance down from

the top that you glue roof supports is not critical. Some roofs are level and some will slope front to

back. Be sure they are placed even with each other so roof will lie reasonably flat. Glue roof to top of

roof support strips. Glue chimney to top of roof.

3-dimensional effect for the sign decals

A. Apply appropriate Dry Transfer Decals and paper

signs (suggested list above) to surface of scrap styrene

plastic, left over from roofs.

B. Using a hobby knife, carefully cut out plastic-

backed signs as close to the edges as possible

(Fig. 1a).

C. Blacken white edges of plastic backing with a

black marker (Fig. 1b).

D. Glue sign to desired building (Fig. 1c).

CANOPY INSTRUCTIONS

Paint canopies the color of your choice and let

them dry. Cut carefully around canopies using a

sharp hobby knife. Remove bottoms of canopies

(Fig. 4). Sand, trim and

test fit canopies. Touch up

bottom of canopies before

attaching.

Glue parts to Rosie’s and

Dad’s (Fig. 5).

ROOF INSTRUCTIONS

Dyden #1 (RP13) building has special directions for roof installation. NOTE: To assemble gable roof, see #201 Roof Assembly Instructions

(enclosed in Dyden #1 individual building package). The illustration of the roof assembly 201-4 wall and 201-2 wall are opposite of building

assembly illustration.

For the rest of the kits, proceed as follows. Measure inside dimensions of roof opening(s). Draw measurements on cardboard, then cut out and

test fit cardboard. Make changes in cardboard roof as required until it fits well. Trace cardboard roof on styrene roof sheet and cut out by scoring

with hobby knife along straightedge and snapping off excess plastic. Test fit and make adjustments with hobby knife. (Save scrap roof material for

signs.) Paint roof a flat black such as Floquil “Grimy Black.” Glue in place according to type of chimney your kit has (see below).

Molded In Chimney (RP1, RP2, RP7, RP8, RP9, RP14, RP15)

If your building has chimney(s) molded in as part of wall, insert roof from bottom of building and glue to bottom of chimney(s). Kits include

square .080 x .080 inch styrene plastic strips to make roof supports (Fig. 6). Cut strips for supports. For small buildings (RP1, RP7, and RP15),

roof support strips on two opposite walls will do. For large buildings (RP2, RP8, RP9, and RP14), you will need to put a support strip on every

wall. Place each strip under roof so it fits flush to underside of roof and to inside of wall where roof and wall meet. Glue to both the underside of

roof and to wall.

NOTE: In striving for authenticity in our Dry

Transfer Decals, some detail has been lost

In the process of reducing life-sized signs for

reproduction in HO scale. This is not a misprint,

rather an effect of the reduction. See the entire

line of Woodland Scenics Dry Transfers and

castings at your favorite hobby shop.

Fig. 1a Fig. 1b Fig. 1c

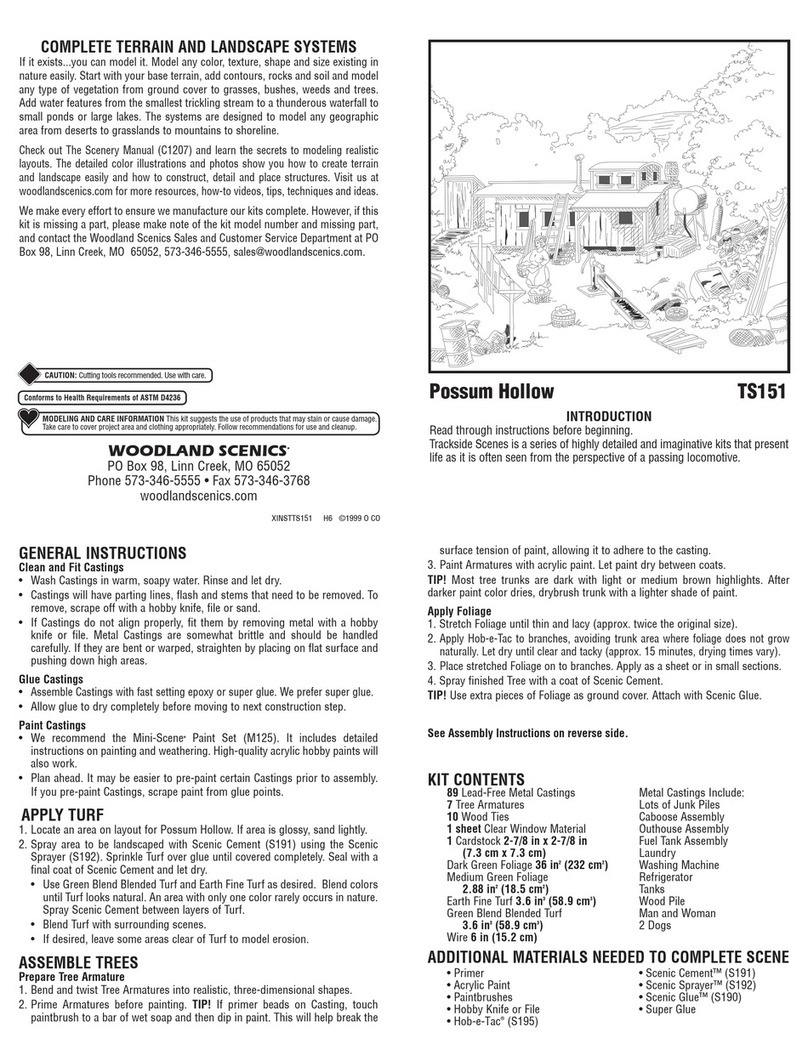

GENERAL INSTRUCTIONS FOR WHITE METAL CASTINGS

The River Pass Building Kits contains more than 200 white

metal castings. These details add life to your layout and make

it more than a set of buildings. They are easy to assemble,

paint and place. Follow these instructions for preparing the

castings. Refer to box photos for some general placement

ideas.

PREPARATION OF METAL CASTINGS

Remove parting lines, flash and stems with a hobby knife

(i.e., X-Acto), diagonal cutters (i.e., Fiskars), sandpaper or

file. Test fit castings. Note: Castings bend easily and should

be handled carefully. Straighten bent or warped castings.

Wash all metal castings in soapy water to remove residue

caused by molding process. Rinse and allow parts to dry. Plan ahead. It is often easier to paint certain castings before assembly. We recommend

using a primer coat and then painting castings with a high quality, flat paint. If you paint first, scrape paint from glue points before gluing. Touch

up paint, if necessary, after assembly. Glue castings together with a fast-setting epoxy or cyanoacrylate, such as “Super Glue” (a thick, gap-filling

cyanoacrylate is recommended).

Fig. 5

Rosie’s

RP9

Fig. 11

Fig. 11a

Fig. 13

OPTIONAL IDEA

To complete the illusion that the building is occupied, place black paper (included in this kit) diagonally from corner to corner inside

building to block light from entering (see cutting diagram below).

#RP1

BIG

DEAL

PAWN

4

½

''

3

¼

'' 4''

4

¼

''

#RP5

MAINSTREET

APTS. #2

#RP6

RIVER PASS

APTS. #2

4''

3

¼

''

4

¼

'

3

¼

''

#RP15

DAD’S MUSEUM

4

½

''

6

¼

''

#RP2

RIVER PASS

VOLUNTEER FIRE DEPT.

3

¾

''

7

¾

''

#RP4

DYDEN #3

3

¼

''

5

½

''

#RP10

DON’S HARDWARE

4

½

''

5''

#RP11

PATRIOT APPLIANCE

8

½

''

6''

#RP12

RIVER’S HOTEL

Tape two pieces of black paper together for River’s Hotel

3

¾

''

5

¼

''

#RP9

ROSIE’S

4

½

''

4

½

''

#RP14

MERLS DRY GOODS

4

¼

''

3

¼

''

#RP3

MARGARET’S

MARKET/BOOT

REPAIR

3

½

''

4

¾

''

#RP8

FLOYD’S BARBER SHOP/

BINDER BOOK SHOP

3''

3

¼

''

#RP7

DYDEN

#2

6

½

''

5

½

''

#RP7

DYDEN #2

1

½

''

1

½

''

#RP13

DYDEN #1

Fig. 15

TRAILER FISHING DOCK BILLBOARD

FENCE CONSTRUCTION (read entire instruction before beginning)

• With light strokes, trim one 1/32" thick fence material to two inches wide, using a straightedge and X-Acto knife (Drawing A). The strips should

fall apart. If not, roll between fingers to separate.

• Tape fence template plan to a flat surface.

• Carefully align strips of fence rail on one template

(stagger joints as indicated). Tape in position on

template. Don’t cover posts on template. Using

3/64" thick fence material strips, cut posts to length

indicated on template. Align posts as indicated and

using a fast setting epoxy or cyanoacrylate, glue

railings at railing joints (allow glue to dry). Repeat

for other four fence sections.

• Cut two remaining 1/32" fence material into 7/8"

pickets (Drawing B). Carefully remove fences from

templates, turn over, and randomly glue pickets.

When dry, trim bottom of pickets (Drawing C).

Refer to box photo for suggested fence placement.

Building placement and available space will

determine the length of fence. Adjust to fit your area.

• Save scrap to board up windows on buildings

and to create junk piles.

Big Deal Pawn

We have supplied a good awning and a torn awning, so that you may decide whether to make Big Deal Pawn look occupied, or give it an abandoned

look. If you like the abandoned look, use the scrap from the wooden fence to create a boarded up look. Glue the boards onto the front door and a few

of the windows (Fig. 12a). We also supplied newspaper print to glue to the inside of the front windows to add to the abandoned look.

SIGN INSTALLATION

Six of the buildings have large signs. Using sign frame as a guide, trace frame on to printed paper signs. Cut and trim sign to fit sign frame. Glue cut signs

to the metal sign castings, using any white glue. Merls Dry Goods (Fig. 10) and Dad’s Museum signs (Fig. 11) are glued to the building as shown in the

illustration, with cyanoacrylate. Big Deal Pawn (Fig. 12), Don’s Hardware (Fig. 13), Patriot Appliance (Fig. 14) and Boot Repair (Fig. 15) will need to have

holes drilled into the side of the building before gluing the signs to the building with cyanoacrylate. Refer to illustrations for placement of the signs.

Dad’s Museum has a two-piece hanging sign (part #52 and #53). Glue #52 to the top of #53 and attach to the building (Fig. 11). There are three signs

exactly the same. Trim one of the sign’s posts and glue to the top of the roof (Fig. 11a). The other two can be used as road signs.

cut

cut

cut

cut

cut

/8"/8"

cut

cut

2"

FENCE MATERIAL

Drawing A

FENCE PICKETS

Drawing C

Section A

Section B

Section D

Section C

Section E

FENCE TEMPLATE

FENCE TEMPLATE

Stagger Joints

Rails

Rails

Posts Rails

Rails

Posts

Posts

Gate

Trim off before installing on layout.

Posts

Drawing B

Part #52

Part

#53

Part #1 Part #5

Part #2

Part #104

Part #105

Part #103

Part #32

Part #30

Part #33 Part #34

Part #31

Part #3

Part #4

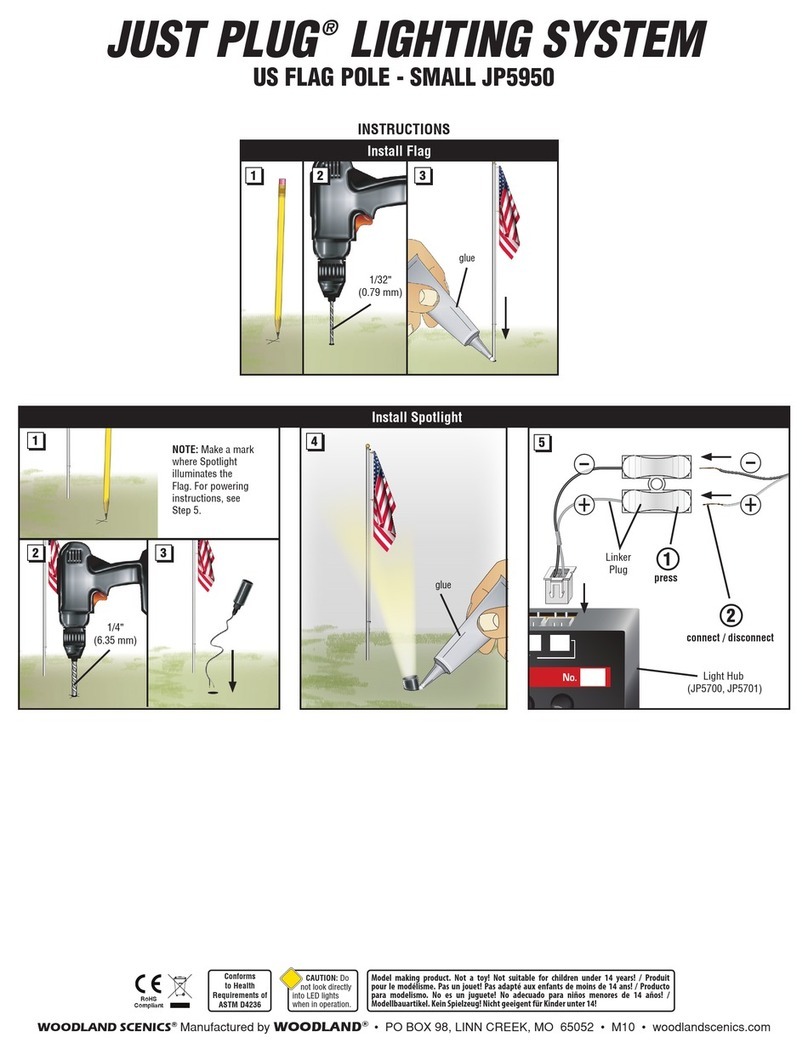

ASSEMBLE FLAG

Carefully cut out the flag of your

choice with a sharp hobby knife.

Fold in half and coat joining faces with

white glue. Wrap around the 3" wire

provided (Fig. 8).

Hold each end of flag (Fig. 9) and

push toward the center to make a

“waving flag.”

Fig. 9

Dad’s

RP15

Fig. 6

Support

strip

Side wall

Assembled

chimney

Front wall

MOLDED IN CHIMNEY

Fig. 7

Support

strip

Roof in

from top

Side wall Front wall

ONE PIECE CHIMNEY

Fig. 10

Fig. 14

Fig. 12 occupied abandoned

Plastic-backed Signs

It is best to back the following signs with the scrap

styrene plastic left over from making the roofs of

your buildings:

• road and traffic signs

• railroad crossings

• firehouse shield

• River’s Hotel

• Dyden #3

• Margaret’s

• Clabber Girl

• Groceries

• Ice

• Home on the Range

• Modern Electric

Cookery

• Showroom

• Dry Goods House

Fig. 4

Bottom

Fig. 8

glue

Fig. 12a