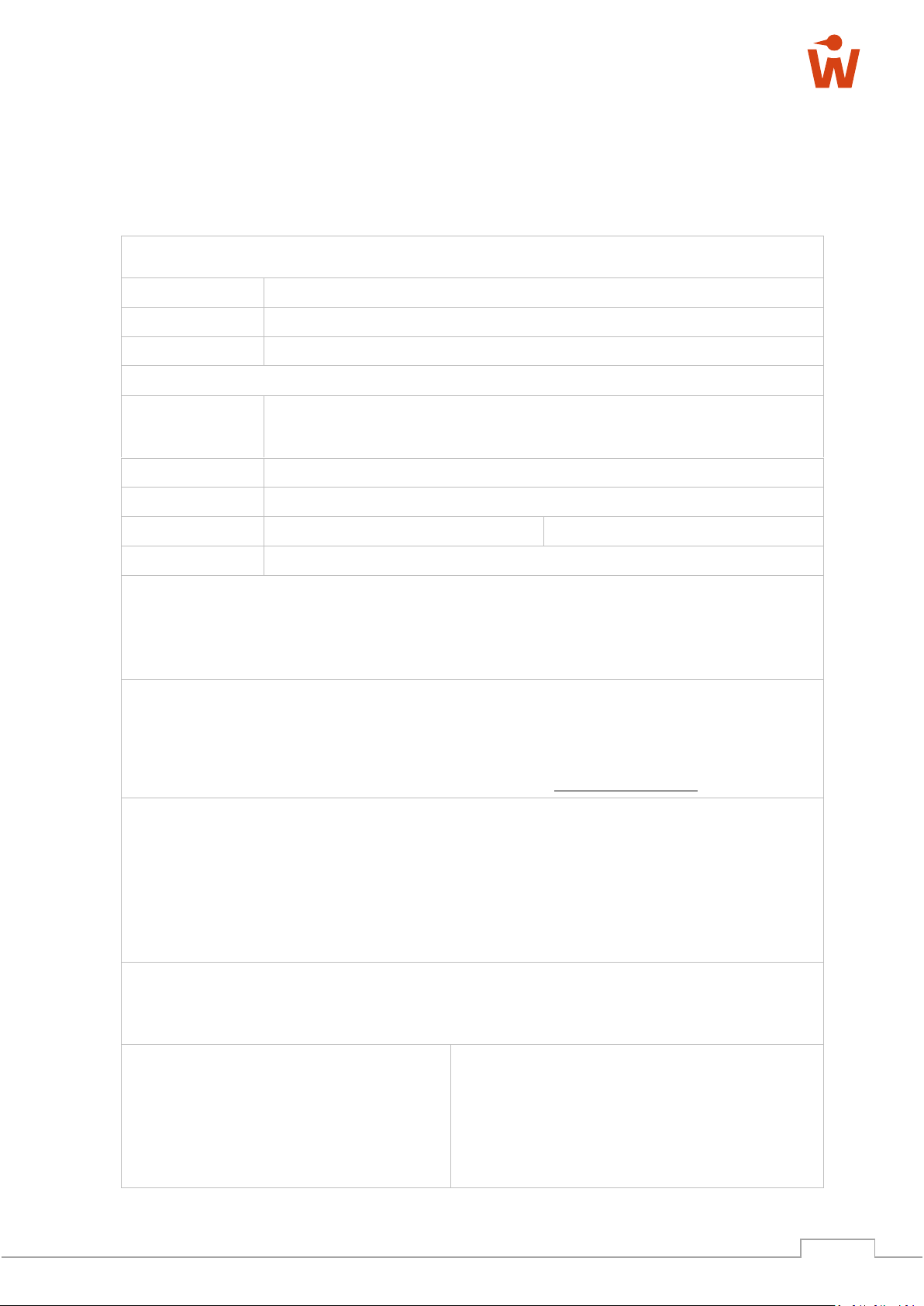

6.2 Emission Levels ..................................................................................................................................................... 24

6.2.1 Noise Information ............................................................................................................................................................24

6.2.2 Noise Emission Values......................................................................................................................................................24

6.3 Workplace Requirements ..................................................................................................................................... 24

7Installation and Connection.......................................................................................................................... 25

7.1 Check Delivery Conditions .................................................................................................................................... 25

7.2 Transport to the Installation Site .......................................................................................................................... 25

7.3 Machine Installation ............................................................................................................................................. 25

7.4 Temporary Storage ............................................................................................................................................... 26

7.5 Lashing in a Transport Vehicle .............................................................................................................................. 26

7.6 External Extraction Unit........................................................................................................................................ 26

8Electrical Connection.................................................................................................................................... 27

8.1.1 Supply Cable and External Fuse Protection......................................................................................................................27

8.1.2 Check Direction of Rotation .............................................................................................................................................27

9Components and Controls............................................................................................................................ 28

10 Mounting and Preparation........................................................................................................................... 29

10.1 Fitting the Stop Rod .............................................................................................................................................. 29

10.2 Fitting the Movement Handle............................................................................................................................... 29

10.3 Fitting the Eccentric Clamps.................................................................................................................................. 29

10.4 Fitting the Mitre Fence ......................................................................................................................................... 30

11 Commissioning ............................................................................................................................................. 30

11.1 Control Panel ........................................................................................................................................................ 30

11.2 Switching the Machine ON and OFF ..................................................................................................................... 30

11.3 Switching the Drill Spindle ON and OFF ................................................................................................................ 30

12 Adjustment and Operation........................................................................................................................... 31

12.1 Clamping and Replacing a Drilling Bit ................................................................................................................... 31

12.2 Pre-setting’s for Mortising.................................................................................................................................... 31

12.3 Operating the Eccentric Clamps............................................................................................................................ 31

12.4 Operating the Mitre Fence ................................................................................................................................... 32

12.5 Clamping Workpieces at the Mitre Fence............................................................................................................. 32

12.6 Height Setting via Handwheel............................................................................................................................... 32

12.7 Tilting the Drilling Unit.......................................................................................................................................... 33

12.8 Setting the Drilling Length and Drilling Depth Stops............................................................................................. 33

12.8.1 Set Drilling Length Stop....................................................................................................................................................33

12.8.2 Setting the Drilling Depth Stops.......................................................................................................................................33

12.9 Mortising............................................................................................................................................................... 34

12.10 Characteristic when drilling dowel holes at an angle to the wood fibre............................................................... 34

13 Dowel Indexing Device (Option)................................................................................................................... 35

13.1 Fitting the Dowel Indexing Device ........................................................................................................................ 35

13.2 Using the Dowel Indexing Device.......................................................................................................................... 35

14 Troubleshooting ........................................................................................................................................... 36

15 Maintenance and Inspection........................................................................................................................ 37