3

operation.

1.6.2 This device should be operated by professional and qualified

dentist in qualied hospital or clinic.

1.6.3 Do not directly or indirectly place this device near heat source.

Operate and store this device in reliable environment.

1.6.4 This device requires special precautions regarding electromagnetic

compatibility (EMC) and must be in strict accordance with the EMC

information for installation and use. Do not use this equipment

especially in the vicinity of fluorescent lamps, radio transmitting

devices, remote control devices, handheld and mobile high-frequency

communication devices.

1.6.5 Long time use of Reciprocating Motion Mode may result

in handpiece overheat, thus it should be left to cool for use. If the

handpiece is overheated frequently, please contact local distributor.

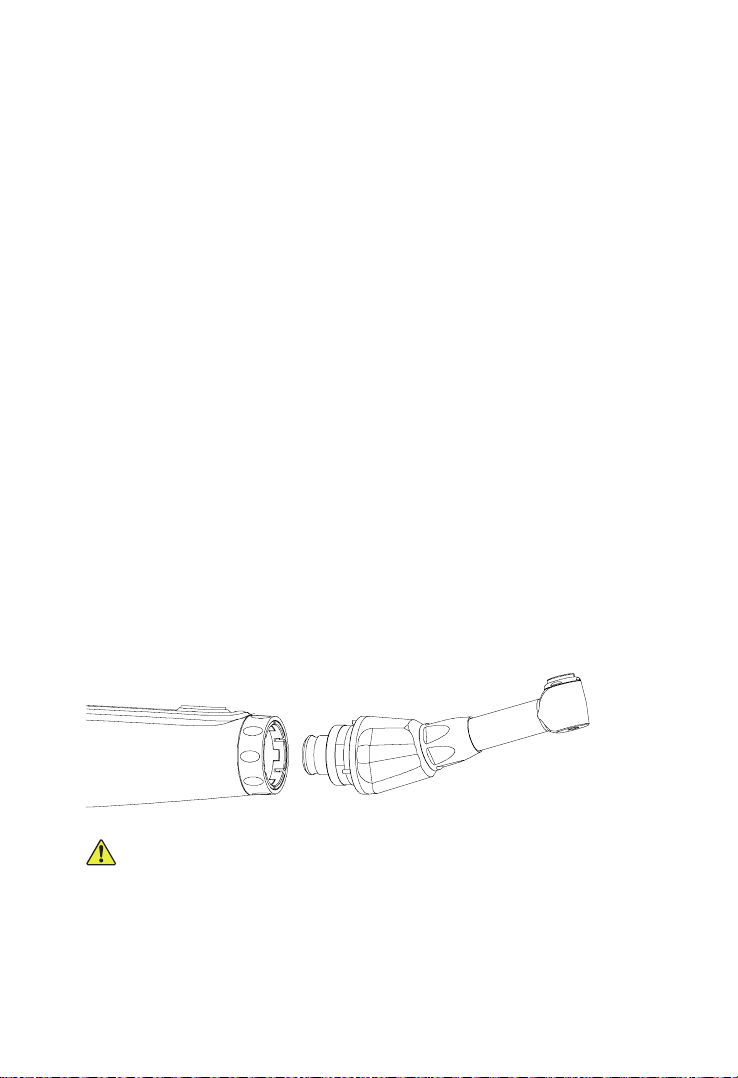

1.6.6 Please use the original contra-angle. Otherwise it will not be used

or cause adverse consequences.

1.6.7 Please do not make any changes to the device. Any changes may

violate safety regulations, causing harm to the patient. There will be no

promises of any modication.

1.6.8 Please use original power adapter. Other power adapter will result

in damage to lithium battery and control circuit.

1.6.9 The handpiece cannot be autoclaved. Use disinfectant of neutral

pH value or ethyl alcohol to wipe its surface.

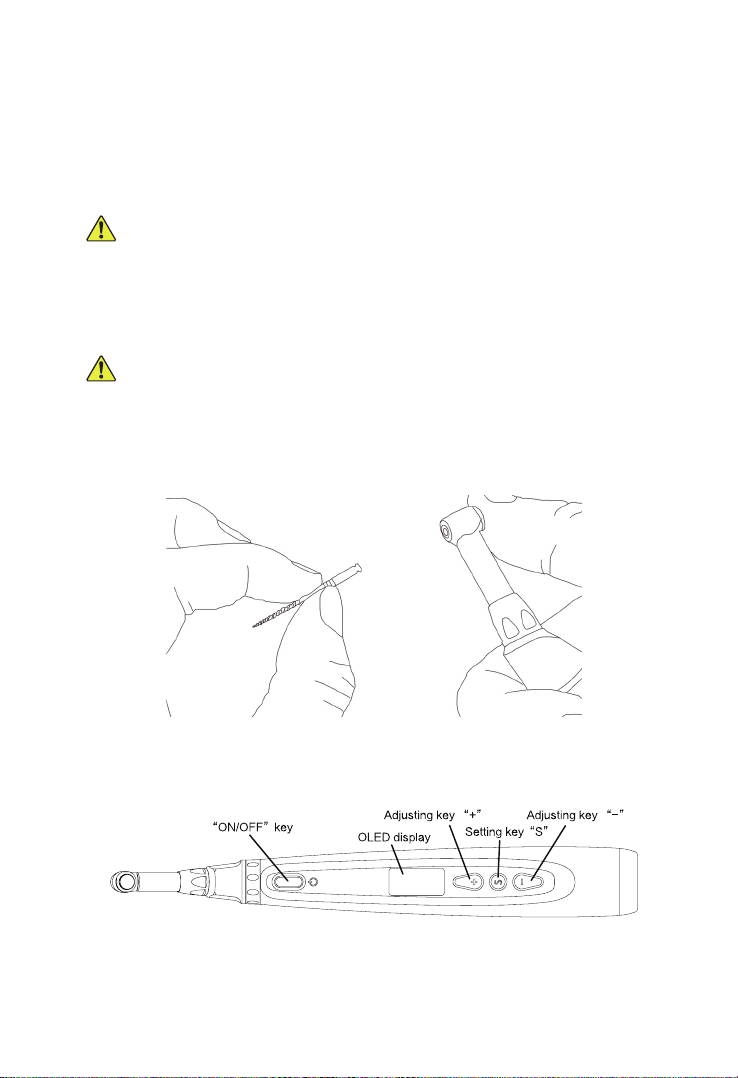

1.6.10 Before the contra-angle stopping rotating, do not press the push

cover of contra-angle. Otherwise the contra-angle will be broken.

1.6.11 Before the handpiece stopping rotating, do not remove the

contra-angle. Otherwise the contra-angle and the gear inside handpiece

will be broken.

1.6.12 Please confirm whether the file is well installed and locked

before starting the handpiece.

1.6.13 The le of Continuous Rotation Mode shall not be used under

Reciprocating Motion Mode and vice versa.

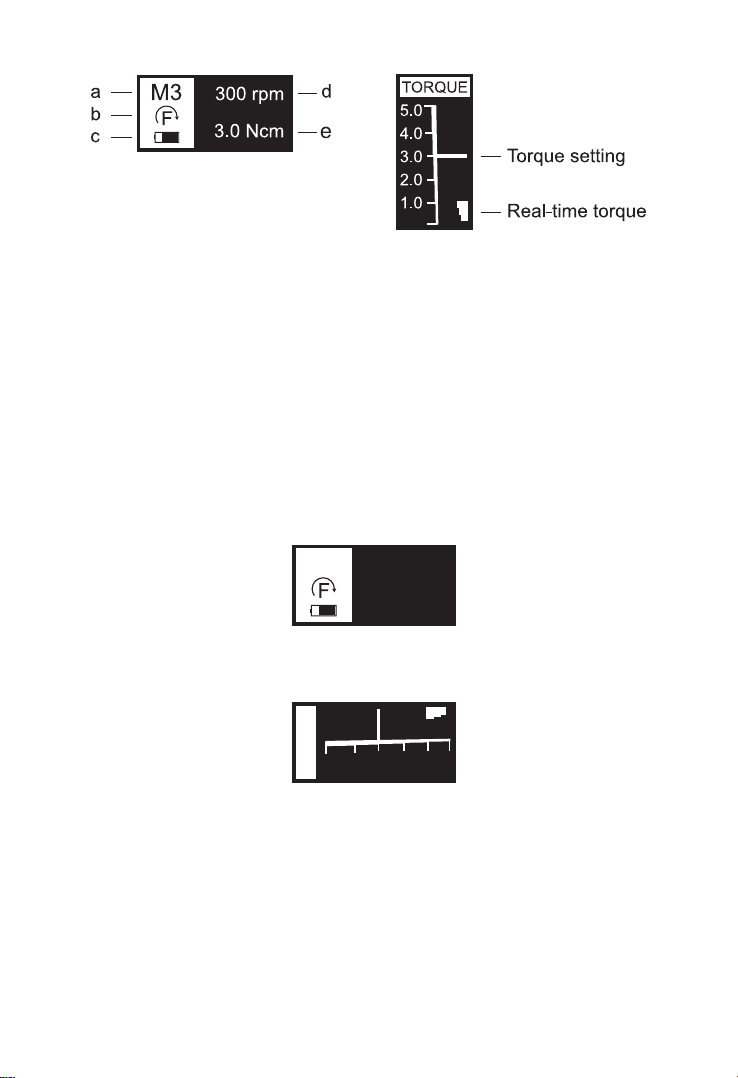

1.6.14 Please set torque and speed as per the recommended