Table of contents

1General Information................................................................................................................ 11

1.1 About This Manual.................................................................................................................... 11

1.1.1 Revision History........................................................................................................................ 11

1.1.2 Depiction Of Notes And Instructions......................................................................................... 11

1.2 Copyright And Disclaimer.......................................................................................................... 12

1.3 Service And Warranty............................................................................................................... 13

1.4 Safety........................................................................................................................................ 13

1.4.1 Intended Use............................................................................................................................. 13

1.4.2 Personnel.................................................................................................................................. 14

1.4.3 General Safety Notes................................................................................................................ 15

1.4.4 Protective Equipment And Tools............................................................................................... 18

2 System Overview..................................................................................................................... 19

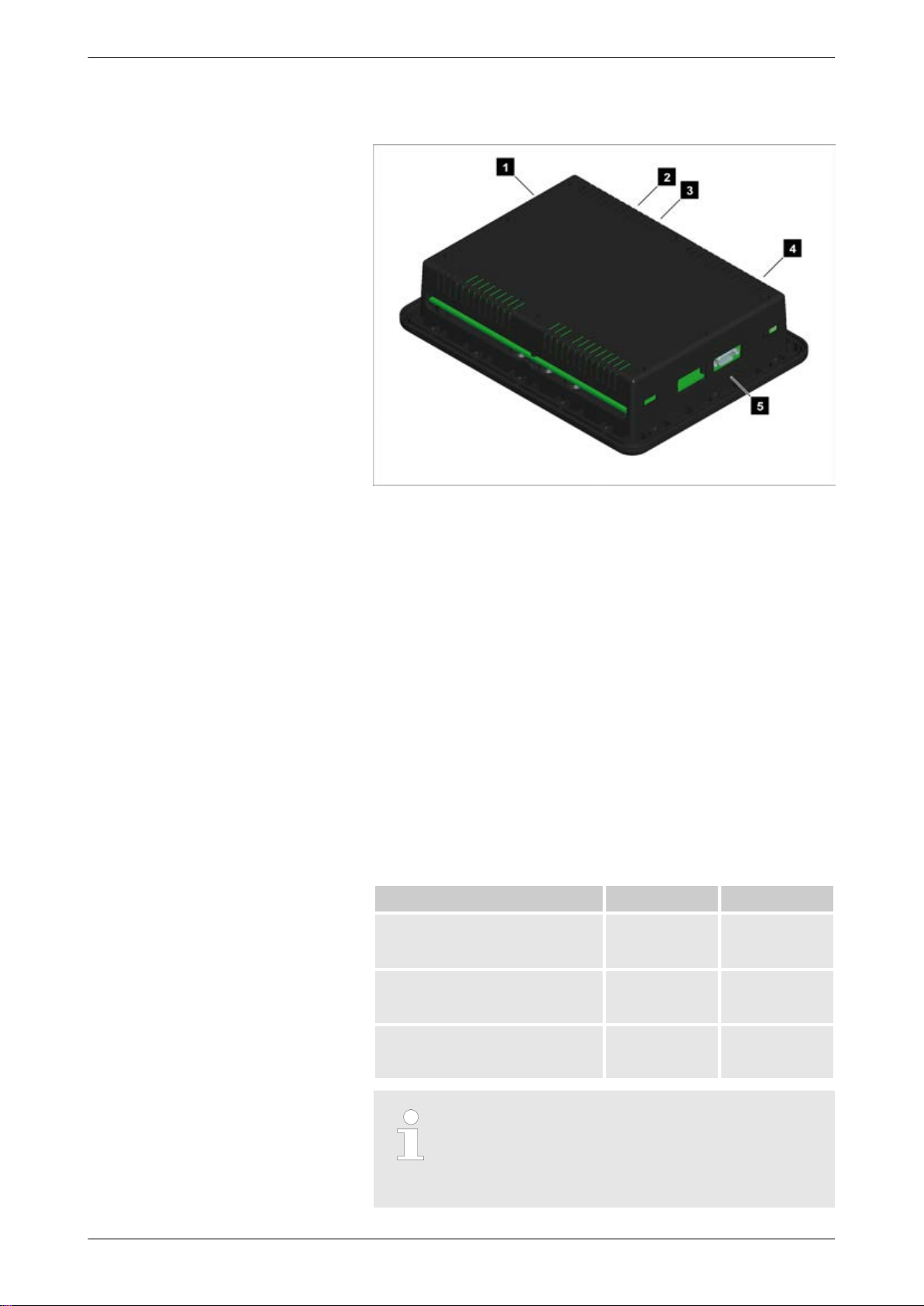

2.1 Display And Status Indicators................................................................................................... 19

2.2 Hardware Interfaces (Terminals)............................................................................................... 19

2.3 Device Update........................................................................................................................... 20

2.3.1 Software Version....................................................................................................................... 20

2.3.2 Update....................................................................................................................................... 22

2.3.3 Troubleshooting......................................................................................................................... 24

3 Installation............................................................................................................................... 27

3.1 Mount Unit (Plastic Housing)..................................................................................................... 27

3.1.1 Clamp Fastener Installation....................................................................................................... 28

3.1.2 Screw Kit Installation................................................................................................................. 29

3.2 Setup Connections.................................................................................................................... 31

3.2.1 Terminal Allocation.................................................................................................................... 31

3.2.2 Wiring Diagram.......................................................................................................................... 32

3.2.3 Power Supply............................................................................................................................ 33

3.2.4 Relay Output............................................................................................................................. 34

3.2.5 Serial Interface.......................................................................................................................... 34

3.2.5.1 RS-232 Interface....................................................................................................................... 34

3.3 CAN Bus Interface..................................................................................................................... 35

4 Configuration........................................................................................................................... 39

4.1 Basic Setup............................................................................................................................... 39

4.1.1 Configure Language.................................................................................................................. 39

4.1.2 Configure Display...................................................................................................................... 39

4.1.3 Lamp Test................................................................................................................................. 39

4.1.4 Enter Password......................................................................................................................... 40

4.1.5 Password System...................................................................................................................... 42

Table of contents

37534C RP-3000 | Remote Panel 7