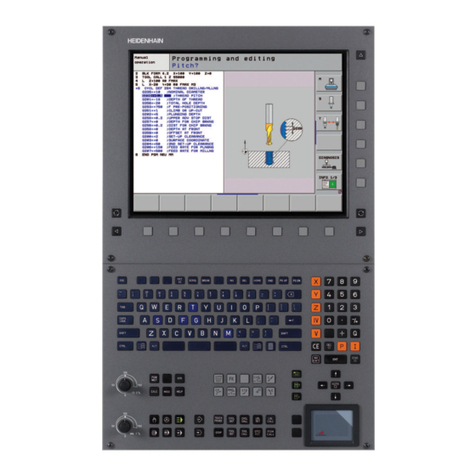

HEIDENHAIN MANUALPLUS 4110 User manual

Other HEIDENHAIN Control Panel manuals

HEIDENHAIN

HEIDENHAIN MANUALPLUS 620 User manual

HEIDENHAIN

HEIDENHAIN ITNC 530 - CONVERSATIONAL PROGRAMMING User manual

HEIDENHAIN

HEIDENHAIN TNC 640 User manual

HEIDENHAIN

HEIDENHAIN TNC 620 User manual

HEIDENHAIN

HEIDENHAIN ND 1100 - V2.15.0 GUIDE User manual

HEIDENHAIN

HEIDENHAIN TNC 620 User manual

HEIDENHAIN

HEIDENHAIN ND 1200 - V2.16 User manual

HEIDENHAIN

HEIDENHAIN POSITIP 8000 User manual

HEIDENHAIN

HEIDENHAIN ITNC 530 - CYCLE PROGRAMMING User manual

HEIDENHAIN

HEIDENHAIN 548431-05 User manual