PSE-PRECISION SPRAY EQUIPMENT®, a divison of Green Leaf, Inc. 9490 N BALDWIN ST FONTANET, IN 47851 www.green-leaf.us 800-654-9808

a division of Green Leaf, Inc

®

PRECISION SPRAY EQUIPMENT

PSE

®

®

— SPEED CHART —

— CALIBRATION

— AFTER SPRAYING

— WINTER STORAGE

After use, fill the sprayer part way with water. Start the

sprayer and allow clear water to be pumped through the

plumbing system and out through the spray wand and

boom. Refill the tank about half full with plain water and

use a chemical neutralizer such as Nutra-Sol® or equiv-

alent and repeat cleaning instructions. Flush the entire

sprayer with the neutralizing agent. Follow the chemical

manufacturer’s disposal instructions of all wash or

rinsing water.

Drain all water and chemical out of sprayer, paying

special attention to pump and valves. These items are

especially prone to damage from chemicals and

freezing weather. The sprayer should be winterized

before storage by pumping a solution of RV antifreeze

through the entire plumbing. Proper care and main-

tenance will prolong the life of the sprayer.

— OPERATION

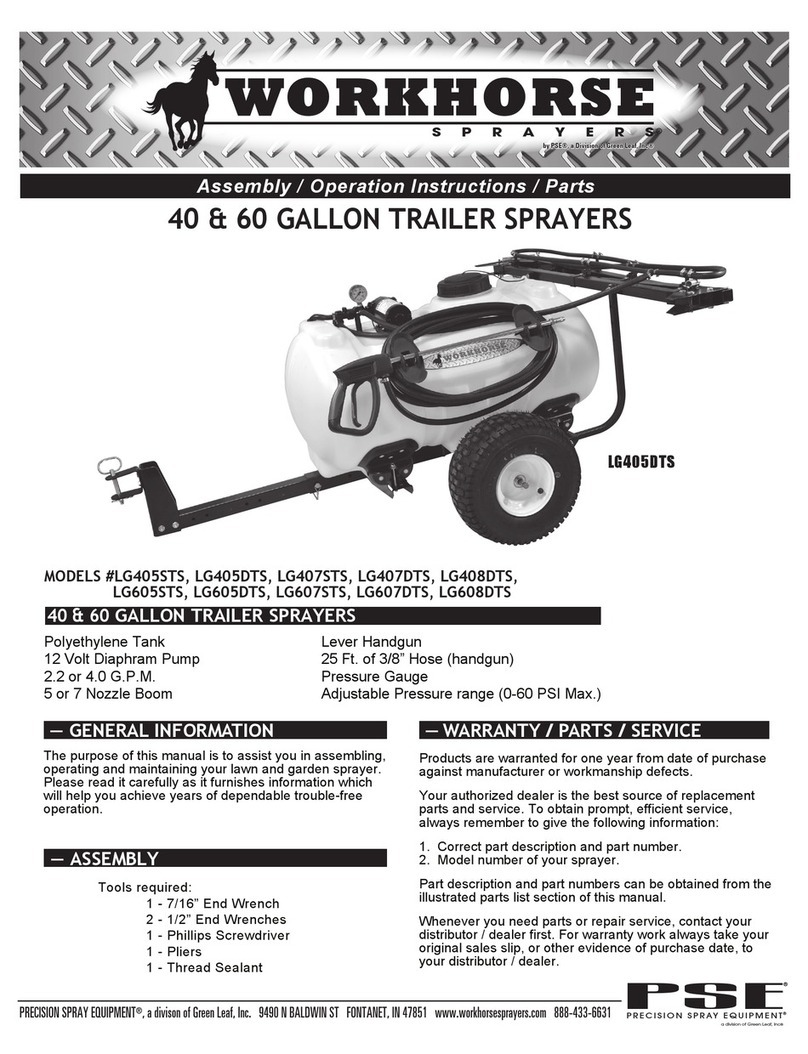

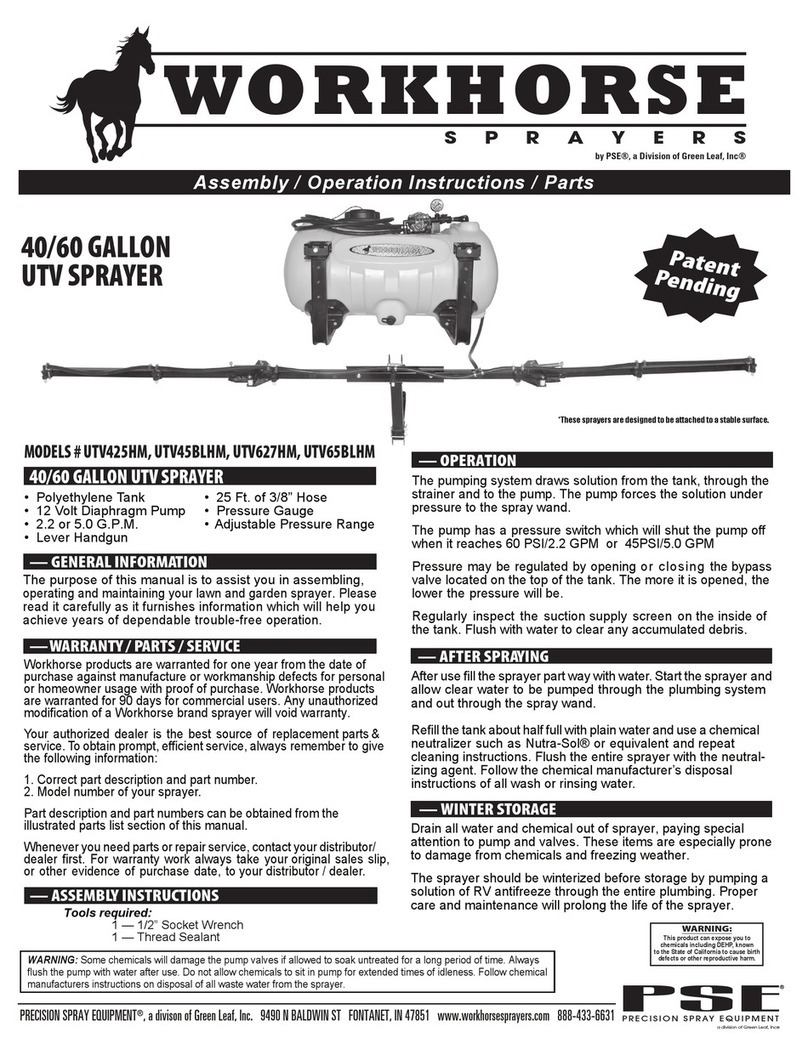

This sprayer is designed to be attached to an ATV rack or

other stable surface. The pumping system draws solution

from the tank, through the strainer and to the pump. The

pump forces the solution under pressure to the spray wand

and spray boom. The pump has a pressure switch which

will shut the pump off when it reaches 60 PSI. Pressure

may be regulated by opening or closing the bypass valve

located on the top of the tank. Also, the spray nozzles can

independently be cycled on and off with the Y-valve

located on the top of the tank. See the illustration in this

manual for more details on using the bypass valve.

Regularly inspect the suction supply screen on the inside

of the tank. Flush with water to clear any accumulated debris.

WARNING: Some chemicals will damage the pump valves if

allowed to soak untreated for a long period of time.Always flush

the pump with water after use. Do not allow chemicals to sit in

pump for extended times of idleness.Follow chemical man-

ufacturers instructions on disposal of all waste water from the

sprayer.

Chemical labels may show application rates in gallons per

acre. Once you know how much you are going to spray

then determine (from the tip chart) the spraying pressure

(PSI), and the spraying speed (MPH). Conditions of

weather and terrain must be considered when setting the

sprayer. Do not spray on windy days. Protective clothing

must be worn in some cases. Be sure to read the chem-

ical label carefully. Determining the proper speed of the

tractor can be done by marking off 100, 200 and 300 feet.

The speed chart indicates the number of seconds it takes

to travel the distances.

Set the throttle and with a running start travel the distances.

Adjust the throttle until you travel the distances in the

number of seconds indicated by the speed chart. Once

you have reached the throttle setting needed, mark the

throttle location so you can stop and go again (returning to

the same speed). Add water and proper amount of chem-

ical to tank and drive to the starting place for spraying.

When you are ready to spray, turn the boom valve to the

“on” position. This will start solution spraying from the tips

once the pump is turned on. The pressure will decrease

slightly when the boom is spraying.

—

BOOMLESS NOZZLE SPRAY INFORMATION

When boom spraying, the recommended boom nozzle

height is 24”- 48” above ground level. (Fig. 4)and the pump

pressure should be between 14psi and 18psi (See tip

chart at the bottom of this page). The manifold has

three (3) valves; 2 for left/right spray control on the boom

and the other agitates and adjusts pressure. The pressure

is adjusted while the sprayer is running. We recommend

testing/setting theboom pressure using water. Turn the

pump on and open the ¼ turn valve to the boom; then

adjust the ¼ turn valve on the bypass/agitation line by

opening and/or closing the valve to the desired pressure

(your gauge will indicate pressure). Once desired pressure

has been set, turn off the valve to the boom and leave

the bypass/agitation valve set. It is normal to see a raise

in pressure while the pump is returning to the tank which

also helps to agitate the tank contents. The pressure is

set for the boom; you will also be able to use the wand

while the boom is off without adjusting the setting. The

pump will run until you shut off the pump with the in-line

on/off switch.

SPEED IN MPH Time Required in Seconds to Travel a distance of:

(Miles Per Hour)

100 ft 200 ft 300 ft

1.0

2.0

3.0

4.0

5.0

6.0

7.0

68.0

34.0

23.0

17.0

14.0

11.0

9.7

136

68

45

34

27

23

19

205

102

68

51

41

34

29

1200PS

PSI

20

30

40

GPM

1.0

1.2

1.4

SPRAY

DISTANCE

14 ft.

14 ft.

14 ft.

35

42

49.5

18

21

25

12

14

16.5

9

10

12

7

8

10

6

7

8

5

6

7

1 2 3 4

SPEED (MPH)(1/4” MNPT)

5 6 7

GALLONS PER ACRE

Gallons per 1000 sq. ft = GPM x 136

MPH x Spray Width in Inches

Gallons per Acre = GPM x 5940

MPH x Spray Width in Inches

CONVERSION FORMULAS