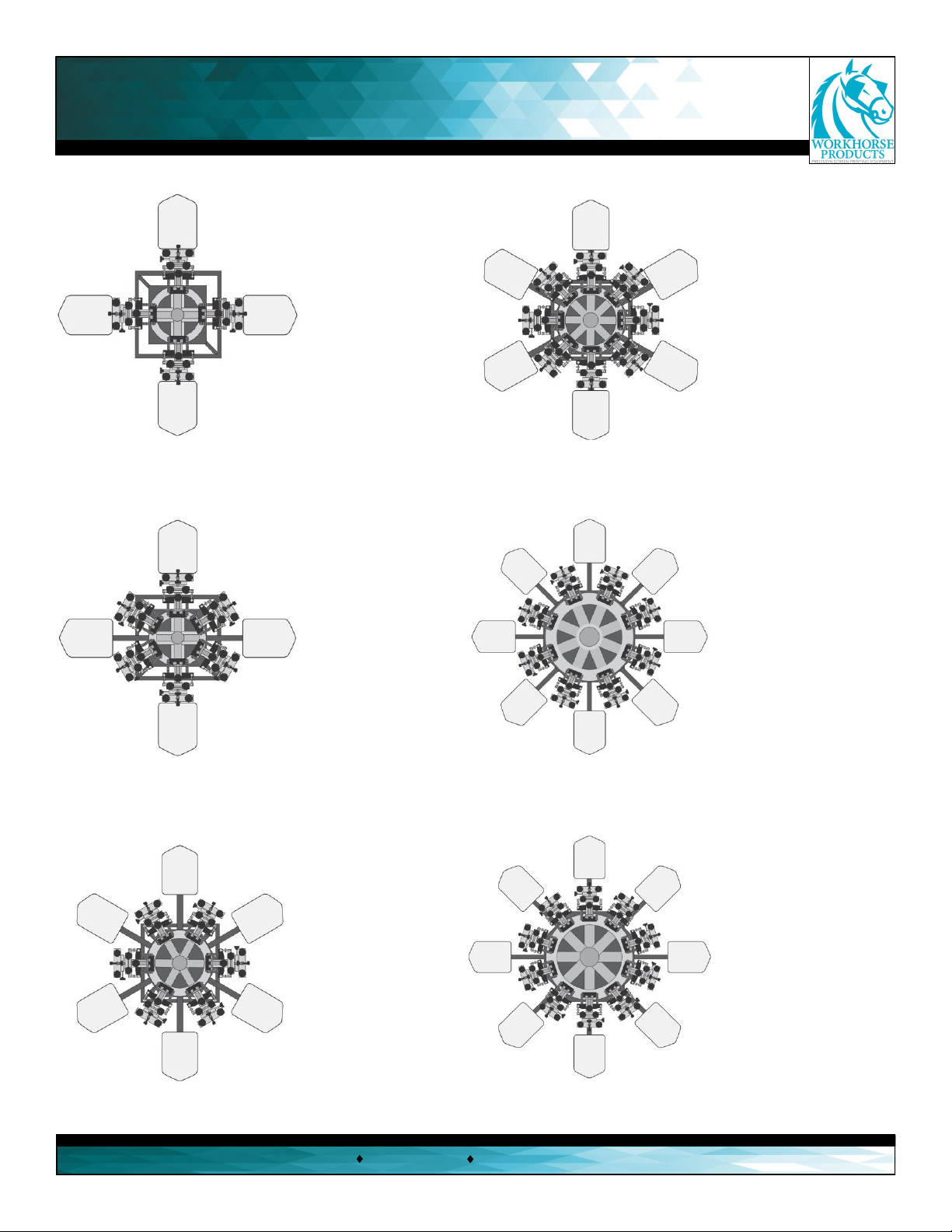

Print Head and Micro Adjustments

3730 E. Southern Avenue, Phoenix, AZ 85040 USA

800-778-8779 Workhorseproducts.com 10

(A) O Contact Adjustment Knob

(B) X and Y Micro Adjustments

(C) Micro Lockdown Knobs

(D) Side-to-Side Adjustment

(E) O Contact Jam Knob

(F) Screen Lockdown Knobs

(G) O Contact Clamp & Screen Holder

(H) Screen Tilt Adjustment

(H1) Screen Tilt Jam Nut

(H2) Screen Tilt Ring

(I) O Contact Foot Pad

Adjusng the O Contact: (A, E & I)

Even though the Mach is automacally set at a

standard o contact, there will be instances that

require adjusng it. To adjust, loosen the o contact

adjustment knob (A) and unscrew/screw down the

o contact adjustment knob to adjust the foot pad

(I) to the desired o contact. Tighten the jam knob

(E) to prevent the o contact knob (A) from moving,

avoid over ghtening.

(A)

(C) (B)

(B)

(C)

(D)

(D)

(E)

(F)

(F)

(G)

(H)

(H1)

(H2)

(I)

(B) (B)

Adjusng the Screen Tilt: (H, H1, & H2)

First, loosen the screen lt jam knob (H1) to create

room to adjust the screen lt and loosen the screen

lt knob (H). Hold the screen and lt it so that the

screen is parallel with the pallet. Then ghten the

screen lt jam knob (H1) unl it’s against the

screen lt ring (H2). While holding the screen lt

jam knob, ghten the screen lt knob unl it ght-

ens the screen lt jam knob against the screen lt

ring.

Tip: To set the o contact consistently, use two 16x1”

10mm strips of plasc for each distance. Place one strip

on the platen and one at the front and back of the

screen ,adjust the screen lt (H) unl it makes contact

with both strips. This will ensure that the front of the

screen is parallel with the back of the screen.