2 of 10 Workrite Ergonomics | 800.959.9675 www.workriteergo.com

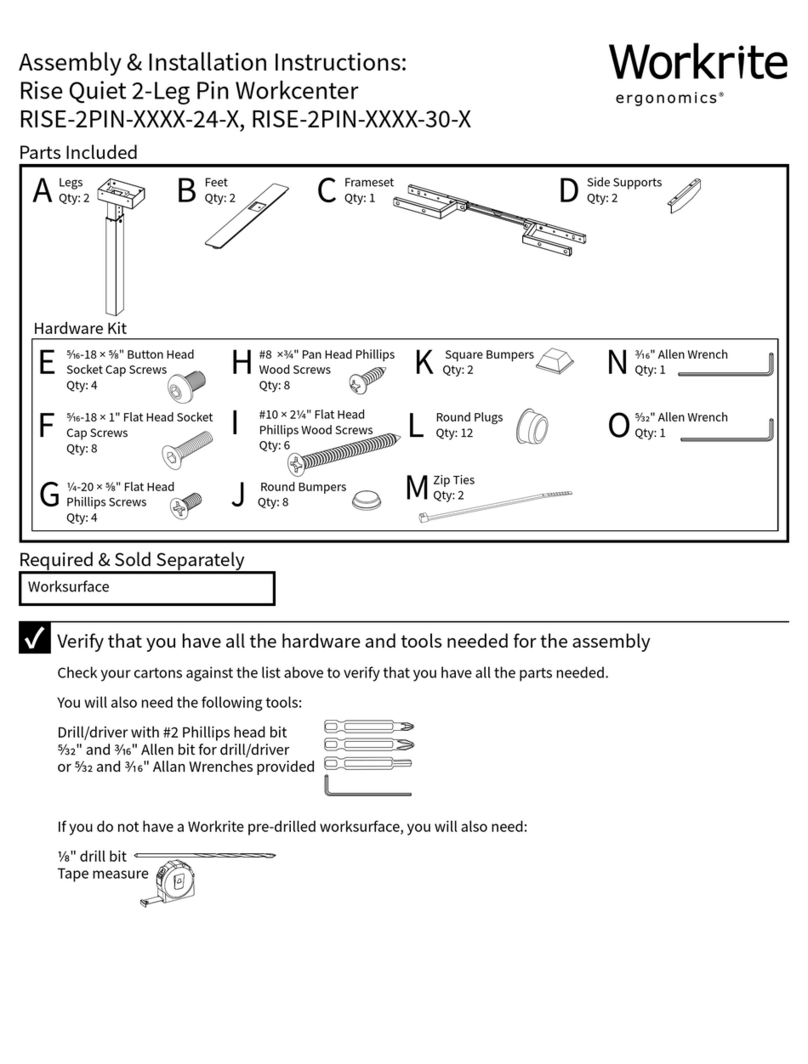

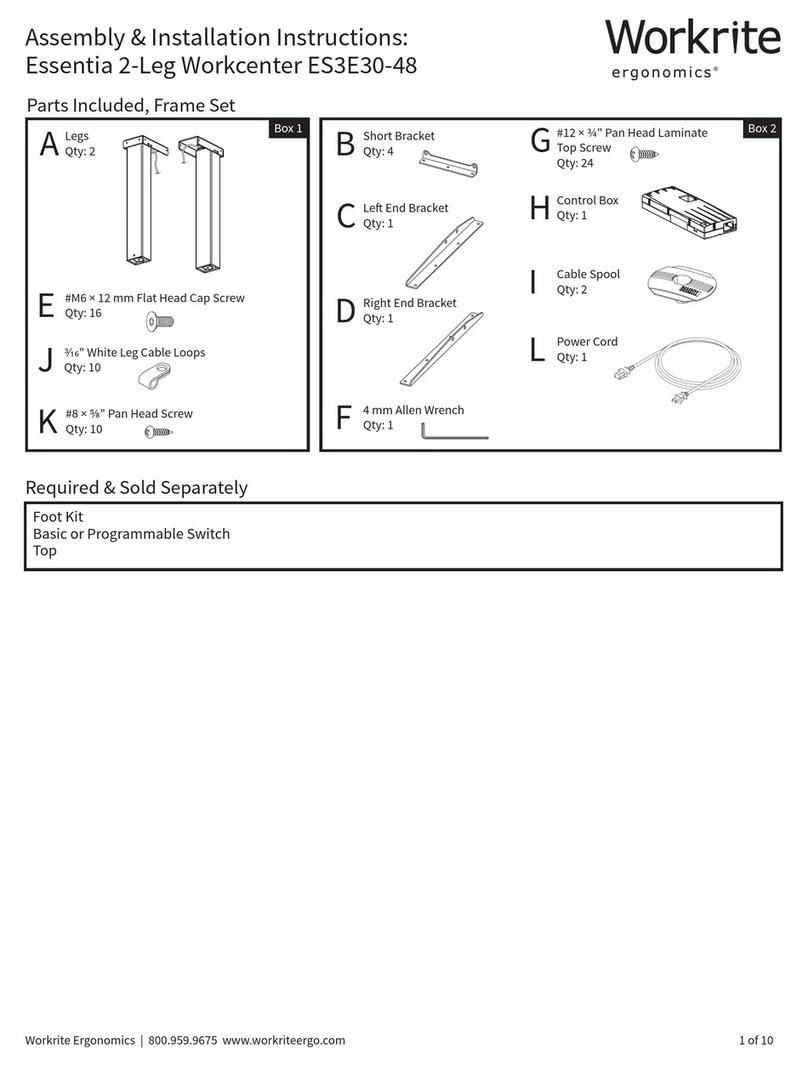

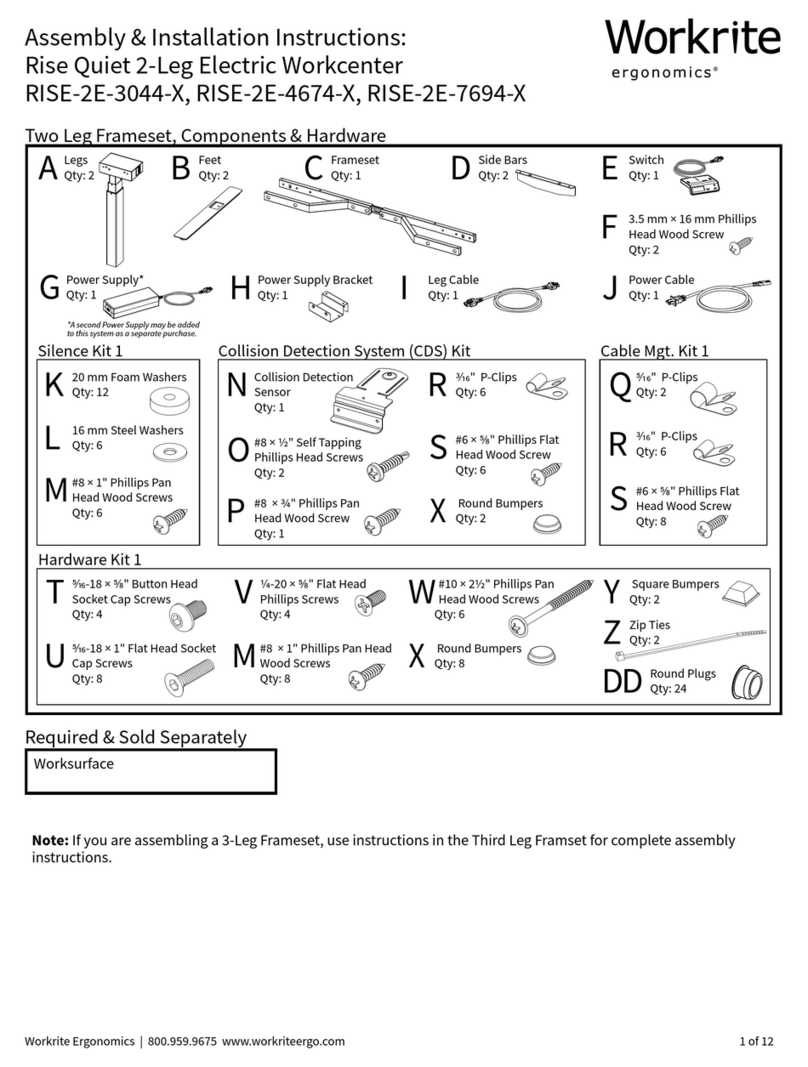

Verify that you have all the tools needed for the assembly

You will need the following tools:

#2 tip Phillips screwdriver or drill/driver

#3 tip Phillips screwdriver or drill/driver

M4 tip bit or 4 mm Allen Wrench (I)

If you do not have a Workrite worksurface, you will also need:

⅛" pilot drill bit

" pilot drill bit

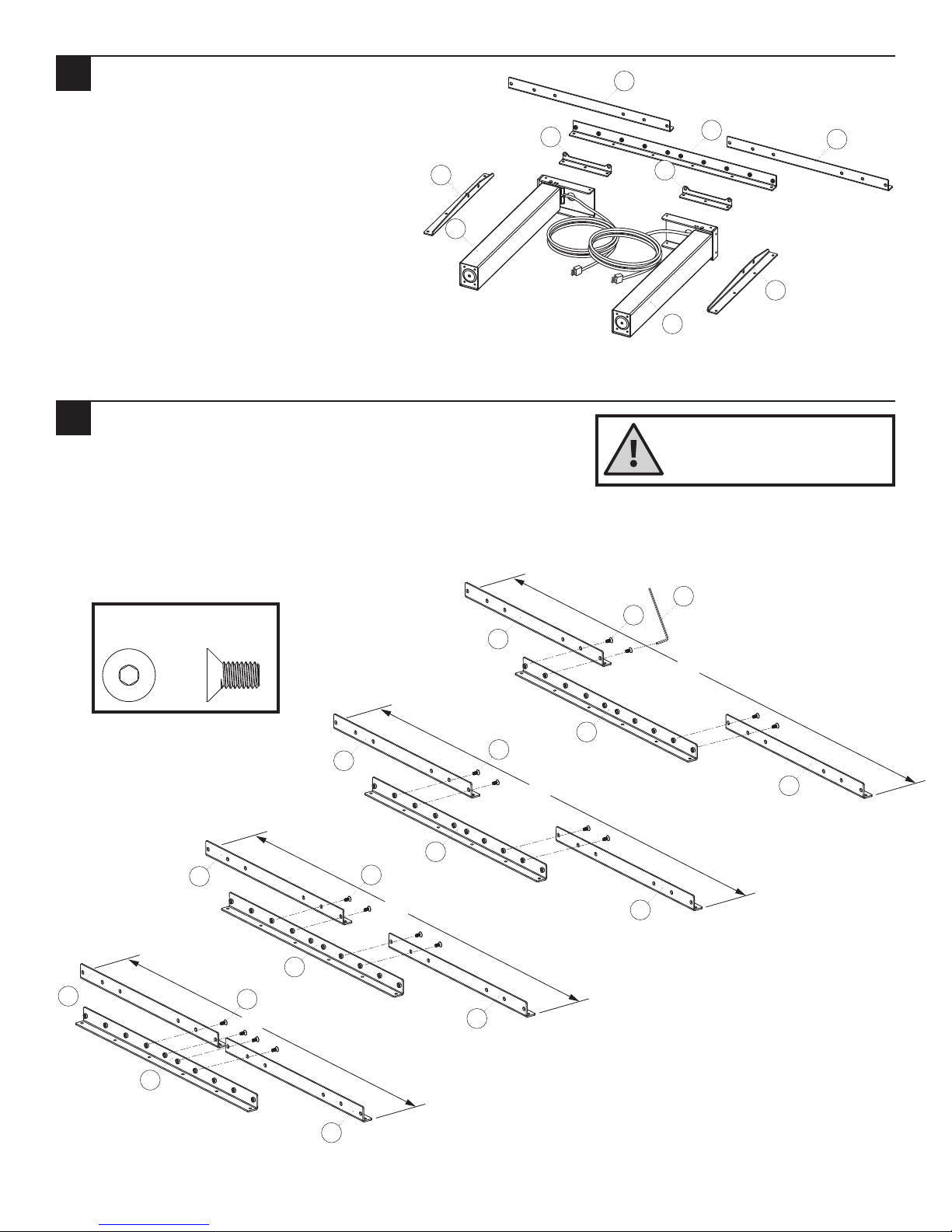

WARNING: Maximum loading of table assembly is 225 lb. (102 kg). Maximum load includes the weight of the

table top itself, any equipment placed upon it, and any equipment suspended or hanging under it. Loading should be evenly distributed

over table surfaces. “Payload Capacity” is the Workrite Ergonomics recommended maximum loading which includes the Workrite sourced

table top.

Essentia 2-leg

V = 120 VAC, 60 Hz / 8 A maximum

IMPORTANT SAFETY INSTRUCTIONS:

When using an electrical furnishing, basic precautions should always be followed, including the following:

Read all instructions before using this Essentia Workcenter.

DANGER:To reduce the risk of electric shock, always unplug this Essentia Workcenter from the electrical outlet before

cleaning.

WARNING:To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Unplug from outlet before putting on or taking o parts.

2. Close supervision is necessary when this furnishing is used by, or near children, invalids, or disabled persons.

3. Use this furnishing only for its intended use as described in these instructions. Do not use attachments not recommended by the

manufacturer.

4. Never operate this furnishing if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or

dropped into water. Return the furnishing to a service center for examination and repair.

5. Keep the cord away from heated surfaces.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8. To disconnect, remove plug from outlet.

9. Each surface intended to support an equipment payload of 225 pounds.

FOR COMMERCIAL USE ONLY

SAVE THESE INSTRUCTIONS

or

✓

IMPORTANT NOTE!

You must complete initialization (Step 13) at the end of

assembly or your workcenter WILL NOT FUNCTION PROPERLY.