Workzone AB1600 User manual

User Manual

DEMOLITION BREAKER

AB1600

Contents

Overview 04

Contents of box 06

Explanation of symbols 07

Introduction 08

Layout 09

Scope of delivery 09

Intended use 10

Safety regulations 10

Before starting the equipment 15

Operation 15

Technical data 16

Maintenance 18

Electrical connection 19

Disposal and recycling 20

Troubleshooting 20

MODEL:AB1600 PRODUCT CODE: 53670 08/2017

AFTER SALES SUPPORT

1300 855 831 support@scheppach.com.au

AUS

Original instructions

Vers.No. 170420

ALDI guarantees that our exclusive brand products are developed to

our stringent quality specifi cations. If you are not entirely satisfi ed with this

product, please return it to your nearest ALDI store within 60 days from

the date of purchase for a full refund or replacement, or take advantage of

our after sales support by calling the supplier’s Customer Service Hotline.

Made in China

WORKZONE TITANIUM is a registered trademark of ALDI Stores

DISTRIBUTED BY:

ALDI STORES

1 SARGENTS ROAD

MINCHINBURY NSW 2770

www.aldi.com.au

5

OverviewOverview

45Pack contents/parts

Contents of Box

11 x Demolition Breaker

1 x Auxiliary handle

1 x Oil can

1 x Spanner

1 x Pointed chisel

1 x Flat chisel

1 x Storage case

2

3

4

5

6

7

AUS

AB1600

AFTER SALES SUPPORT

support@scheppach.com.au 1300 855 831

MODEL:AB1600 PRODUCT CODE: 53670 08/2017

1

Fig. 1

2

3

6

4

5

6

Fig. 2

Fig. 5

Fig. 3

3

6

9

Fig. 4

2

180°

78

910 11

1 x Pair of carbon brushes8

Fig. 6

a

4

5

AFTER SALES SUPPORT 7

1300 855 831 support@scheppach.com.au

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

AB1600 Explanation of Symbols

m Attention! These operating instructions provide places concerning

your safety which are marked with this indication.

m Caution! Failure to follow these instructions may cause light to

medium risk of injury.

m Warning! Failure to follow these instructions may cause danger to

life or danger of serious injuries!

Explanation of Symbols

Caution - Read the operating instructions to reduce the risk of

inquiry.

Wear safety goggles!

Wear ear-muffs!

Wear a breathing mask!

Wear safety shoes

Wear protective gloves.

60 The product is guaranteed to be free from defects in workmanship

and parts for a period of 60 months from the date of purchase.

Appliance Class II

8AFTER SALES SUPPORT

support@scheppach.com.au 1300 855 831

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

Introduction AB1600

I. INTRODUCTION

Congratulations on choosing to buy a WORKZONE TITANIUM®product.

All products brought to you by WORKZONE TITANIUM®are manufactured to the

highest standards of performance and safety, and as part of our philosophy of cus-

tomer service and satisfaction, are backed by our comprehensive 5 Year Warranty.

We hope you will enjoy using your purchase for many years to come.

Note:

The manufacturer of this device is not liable for damages which arise on or in con-

nection with this device in case of:

• improper handling,

• non-compliance with the instructions for use,

• repairs conducted by third party or non-authorised skilled workers,

• installation and replacement of non-original spare parts,

• improper use,

• failures of the electrical system due to the non-compliance with the electrical

specications and regulations.

Recommendations:

Read the entire text of the operating instructions prior to the assembly and operation

of the device.

These operating instructions are intended to make it easier for you to get familiar

with your device and utilise its intended possibilities of use.

The operating instructions contain important notes on how to work safely, properly

and economically with your machine and how to avoid dangers, save repair costs,

reduce downtime, and increase the reliability and working life of the machine.

In addition to the safety regulations contained herein, you must in any case comply

with the applicable regulations of your country with respect to the operation of the

machine.

Put the operating instructions in a clear plastic folder to protect them from dirt and

humidity, and store them near the machine. The instructions must be read and

carefully observed by each operator prior to starting the work. Only persons who

have been trained in the use of the machine and have been informed on the related

dangers and risks are allowed to use the machine. The required minimum age must

be met.

In addition to the safety notes contained in the present operating instructions and

the special regulations of your country, the generally recognised technical rules for

the operation of identically constructed machines must be observed.

AFTER SALES SUPPORT 9

1300 855 831 support@scheppach.com.au

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

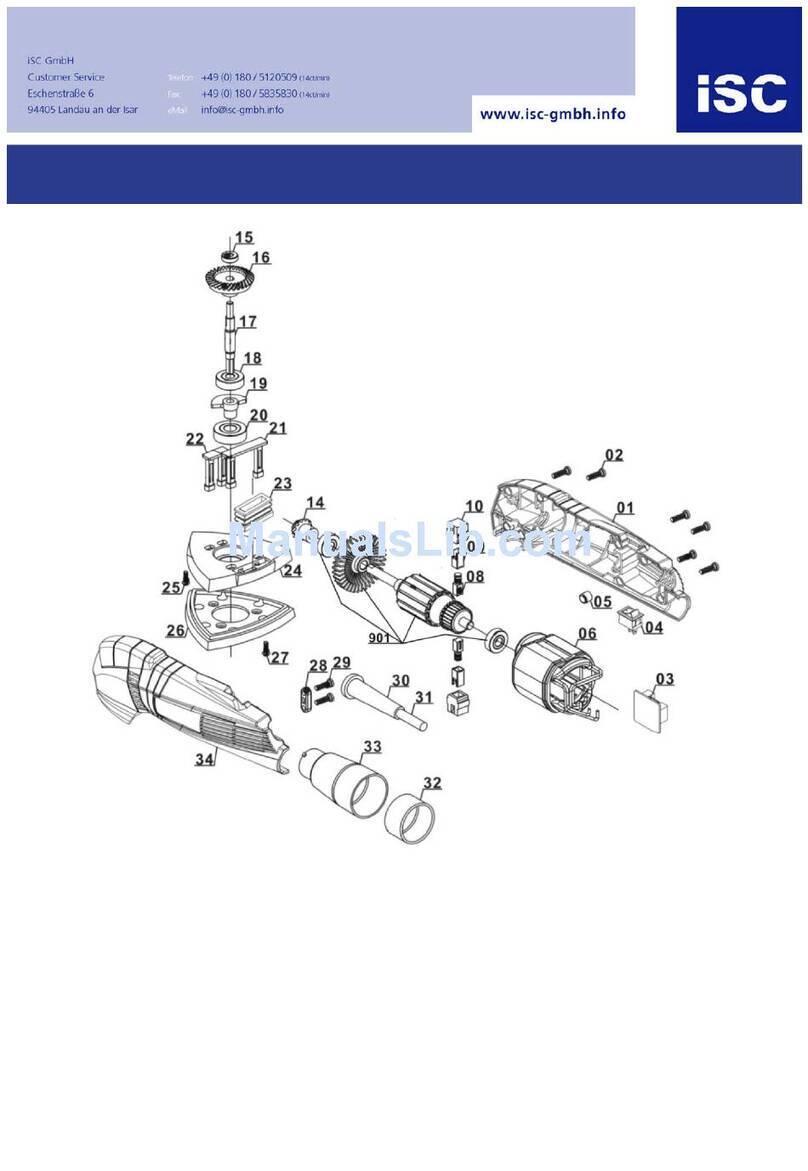

II. LAYOUT (FIG. 1-6)

1. Handle

2. Control switch

3. Auxiliary handle

4. Locking bolt

5. Chuck

6. Inspection window/ Oil ller opening

7. Pointed chisel

8. Flat chisel

9. Spanner

10. Oil can

11. Pair of carbon brushes

III. SCOPE OF DELIVERY

(1x) Demolition breaker

(1x) Auxiliary handle

(1x) Oil can

(1x) Spanner

(1x) Pointed chisel

(1x) Flat chisel

(1x) Pair of carbon brushes

(1x) Storage case

(1x) Instruction manual

(1x) Warranty card

• Open the packaging and remove the device carefully.

• Remove the packaging material as well as the packaging and transport bracing

(if available).

• Check that the delivery is complete.

• Check the device and accessory parts for transport damage.

• If possible, store the packaging until the warranty period has expired.

m Attention!

The device and packaging materials are not toys!

Children must not be allowed to play with plastic bags, lm and small parts!

There is a risk of swallowing and suffocation!

AUS

AB1600 Layout/Scope of Delivery

10 AFTER SALES SUPPORT

support@scheppach.com.au 1300 855 831

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

Intended use/Safety Regulations AB1600

IV. INTENDED USE

This machine is designed for heavy duty demolition and chiseling work using the

appropriate chisel.

The machine is to be used only for its prescribed purpose. Any other use is

deemed to be a case of misuse. The user / operator and not the manufacturer will

be liable for any damage or injuries of any kind caused as a result of this.

Please note that our equipment has not been designed for use in commercial, trade

or industrial applications. Our warranty will be voided if the machine is used in com-

mercial, trade or industrial businesses or for equivalent purposes.

V. SAFETY REGULATIONS

m WARNING Read all safety warnings and all instructions. Failure to follow

the warnings and instructions may result in electric shock, re and/or serious in-

jury. Save all warnings and instructions for future reference The term "power

tool" in the warnings refers to your mains-operated (corded) power tool or bat-

tery-operated (cordless) power tool.

1. WORK AREA SAFETY

a. Keep work area clean and well lit. Cluttered and dark areas invite accidents.

b. Do not operate power tools in explosive atmospheres, such as in the presence

of ammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

c. Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2. ELECTRICAL SAFETY

a. Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodied plugs and

matching outlets will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

AFTER SALES SUPPORT 11

1300 855 831 support@scheppach.com.au

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

AB1600 Safety Regulations

Damaged or entangled cords increase the risk of electric shock.

e. When operating a power tool outdoors, use an extension cord suitable for out-

door use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f. If operating a power tool in a damp location is unavoidable, use a residual cur-

rent device (RCD) protected supply. Use of an RCD reduces the risk of electric

shock.

3. PERSONAL SAFETY

a. Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the inuence of

drugs, alcohol or medication. A moment of inattention while operating power tools

may result in serious personal injury.

b. Use safety equipment. Always wear eye protection. Safety equipment such as a

dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your nger on the switch or energising power tools that have

the switch on invites accidents.

d. Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to rotating part of the power tool may result in personal injury.

e. Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewellery or long hair can be

caught in moving parts.

g. If devices are provided for the connection of dust extraction and collection fa-

cilities, ensure these are connected and properly used. Use of these devices can

reduce dust-related hazards.

4. POWER TOOL USE AND CARE

a. Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b. Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

12 AFTER SALES SUPPORT

support@scheppach.com.au 1300 855 831

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

Safety regulations AB1600

power tools. Such preventive safety measures reduce the risk of starting the power

tool accidentally.

d. Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tools oper-

ation. If damaged, have the power tool repaired before use. Many accidents are

caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in accordance with these in-

structions and in the manner intended for the particular type of power tool, tak-

ing into account the working conditions and the work to be performed. Use of

the power tool for operations different from those intended could result in a hazardous

situation.

5. SERVICE

a. Have your power tool serviced by a qualied repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

6. RECOMMENDATION

We recommend that the tool always be supplied via residual current device with a

rated residual current of 30 mA or less.

ADDITIONAL SAFETY INSTRUCTIONS

• Wear ear protectors. Exposure to noise can cause hearing loss.

• Use the Auxiliary handles supplied with the tool. Losing control of the tool can cause

injuries.

• Hold the equipment by the insulated handles when carrying out work during

which the plug-in tool could strike concealed power cables or its own mains lead.

Contact with a live cable can also make the metal parts of the equipment live and will

cause an electric shock.

Important!

When using equipment, a few safety precautions must be observed to avoid injuries

and damage. Please read the complete operating manual with due care. Keep this

manual in a safe place, so that the information is available at all times. If you give

AFTER SALES SUPPORT 13

1300 855 831 support@scheppach.com.au

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

AB1600 Safety regulations

the equipment to any other person, give them these operating instructions as well.

We accept no liability for damage or accidents which arise due to non-observance of

these instructions and the safety information.

WORKING HINTS

• All protective and safety devices must be mounted on the machine before

beginning work.

• The machine is designed to be operated by one person. The operator is

responsible for all other persons in the working area.

• Observe all safety instructions and warnings attached to the machine.

• See to it that safety instructions and warnings attached to the machine are always

complete and perfectly legible.

• The safety, work and maintenance instructions of the manufacturer as well as the

technical data given in the calibrations and dimensions must be adhered to.

• Relevant accident prevention regulations and other, generally recognized

safety-technical rules must also be adhered to. The machine may only be used,

maintained, and operated by persons familiar with it and instructed in its operation

and procedures. Arbitrary alterations to the machine release the manufacturer

from all responsibility for any resulting damages. The machine may only be used

with original accessories and original tools made by the manufacturer.

• Any other use exceeds authorization. The manufacturer is not responsible for any

damages resulting from unauthorized use; risk is the sole responsibility of the

operator.

• Caution: The use of other tools or accessories than the ones specied in the

operating instructions may present a risk of injury for you.

Residual risks

The machine has been built according to the state of the art and the

recognised technical safety requirements. However, individual residual

risks can arise during operation.

Mechanical hazards related to:

Machine parts or workpieces:

• shape;

• relative location;

• mass and velocity (kinetic energy of elements in controlled or uncontrolled

motion);

• mechanical strength.

• Crushing hazard

• Cutting or severing hazard

• Entanglement hazard

• Drawing-in or trapping hazard

14 AFTER SALES SUPPORT

support@scheppach.com.au 1300 855 831

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

Safety regulations AB1600

Electrical hazards due to:

• Contact of persons with live parts (direct contact)

• Contact of persons with parts which have become live under faulty conditions

(indirect contact)

• Electrostatic phenomena

Hazards generated by noise, resulting in:

• Hearing loss (deafness), other physiological disorders (loss of balance, loss of

awareness)

• Interference with speech communication, acoustic signals.

• Hazards generated by materials and substances (and their constituent ele-

ments) processed or used by the machinery

• Hazards from contact with or inhalation of harmful uids and dusts

• Fire hazard

Hazards generated by neglecting ergonomic principles in machinery design

related to:

• Unhealthy postures or excessive effort

• Hand-arm or foot-leg anatomy

• Local lighting

• Mental overload and underload, stress

• Human error, human behaviour

• Design, location or identication of manual controls

Combination of hazards

Unexpected start up, unexpected overrun / overspeed (or any similar

malfunction) from:

• Failure/disorder of the control system

• External inuences on electrical equipment

• Errors made by the operator (due to mismatch of machinery with human

characteristics and abilities)

• Impossibility of stopping the machine in the best possible conditions

• Variations in the rotational speed of tools

• Failure of the power supply

• Failure of the control circuit

• Errors of tting

• Break-up during operation

• Falling or ejected objects or uids

• Loss of stability / overturning of machinery

AFTER SALES SUPPORT 15

1300 855 831 support@scheppach.com.au

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

AB1600 Before starting equipment/Operation

VI. BEFORE STARTING THE EQUIPMENT

Before you connect the equipment to the mains supply make sure that the data on

the rating plate are identical to the mains data.

Always pull the power plug before making adjustments to the equipment.

Check the oil level before using the machine. Place the machine on the oor with the

tool mounting pointing downwards. The oil must be at least 3 mm above the bottom

edge of the inspection window (6). (Fig. 5)

Check the drilling point for concealed electrical cables, gas and water pipes using a

cable/pipe detector.

Auxiliary handle (Fig. 2 / Item 3)

For safety reasons you must only use the demolition hammer with the Auxiliary

handle. The Auxiliary handle (3) enables you to achieve better stability whilst using

the demolition hammer. The Auxiliary handle (3) can be turned into any required

position. Undo the screw (a) by turning it in the “+” direction. Now turn the Auxiliary

handle (3) into the most comfortable working position for yourself and then tighten

the screw (a) again by turning it in the “-” direction.

Inserting the accessory (Fig. 3)

• Clean the accessory before tting it and apply a thin coating of grease to the

accessory shaft.

• Pull out the locking bolt (4) as far as possible, turn it through 180° and release it.

• Insert the accessory into the tool mounting (5) and push it in as far as possible.

(see Fig. 3)

• Pull out the locking bolt (4) again, turn it through 180° in the opposite direction

and release it.

• Check the lock by pulling the accessory.

Removing the accessory

To remove the accessory, proceed in reverse order.

VII. OPER ATION

This demolition hammer is designed for use in the breaking of hard surfaces - con-

crete and masonry and for the loosening of impacted dirt and soil. Its powerful motor

and attachments ensure the quick and easy removal of material

16 AFTER SALES SUPPORT

support@scheppach.com.au 1300 855 831

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

Operation/Technical data AB1600

The pointed chisel is used mainly for general chiseling and the demolition of mason-

ry, concrete and loose rock. It is particularly well suited to breaking and loosening.

The at chisel is used for general chiseling, demolition and the breaking of masonry,

concrete and loose stone. With its selective breaking action the at chisel is used for

the removal of protruding concrete and masonry or for the removal residual mortar.

m Important!

To avoid the risk of electric shock, the machine must only be held using the two

handles (1/3). You may suffer an electric shock if you chisel into electrical cables or

power supplies.

Switching on and off (Fig. 4)

To switch on:

Press the control switch (2).

To switch off:

Release the control switch (2).

Practical tips

Sharpening chisel accessories

You will only achieve good results if you use sharp chisels. You should therefore

sharpen the chisels promptly to ensure that they produce good results and provide a

long service life. Sharpen the chisels with an angle grinder.

mImportant!

You only require slight contact pressure for chiseling. Excessive contact pressure

will place an unnecessary strain on the motor. Check the chisels at regular intervals.

Sharpen or replace blunt chisels.

VIII. TECHNICAL DATA

Dimensions L x W x H mm 652 x 157 x 276

Blowing force Joule 50

Vibration level m/s² 18.2

Weight kg 16

Motor V~ 230 - 240

Frequency Hz 50

Power input W 1600

Protection class II

Subject to technical modications!

AFTER SALES SUPPORT 17

1300 855 831 support@scheppach.com.au

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

AB1600 Technical data

Noise

Total values determined in accordance with EN 60745.

Sound pressure level LpA 98.6 dB(A)

Uncertainty KpA 0.70 dB

Sound power level LWA 105 dB(A)

Uncertainty KWA 0.70 dB

Wear ear / hearing protection

The impact of noise can cause damage to hearing. Total vibration values (vector

sum of three directions) determined in accordance with EN 60745.

Total vibration values (vector sum of three directions) determined in accordance

with EN 60745.

Chiseling

Vibration emission value ah = 18.2 m/s² K uncertainty = 1.5 m/s²

mImportant!

The vibration value changes according to the area of application of the

electric tool and may exceed the specied value in exceptional circum-

stances.

Reduce noise generation and vibration to a minimum!

Use only equipment that is in perfect condition.

Maintain and clean the equipment regularly.

Adopt your way of working to the equipment.

Do not overload the equipment.

Have the equipment checked if necessary.

Switch off the equipment when not in use.

Wear protective gloves.

The gures quoted are emission levels and are not necessarily safe working levels.

Whilst there is a correlation between the emission and exposure levels, this

cannot be used reliably to determine whether or not further precautions are required.

Factors that inuence the actual level of exposure of the workforce include the

characteristics of the work room and the other sources of noise etc. i.e. the number

of machines and other adjacent processes. Also the permissible exposure level can

vary from country to country. This information, however, will enable the user of the

machine to make a better evaluation of the hazard and risk.

18 AFTER SALES SUPPORT

support@scheppach.com.au 1300 855 831

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

Maintenance AB1600

IX. MAINTENANCE

m Warning! Always pull out the mains power plug before starting any cleaning

work.

Cleaning

Disconnect the mains plug, and wait until the rotating tool stands still. All protection

and safety devices must be immediately re-installed once the repair and

maintenance work is completed. The built-in ball bearings are maintenance-free.

Recommendations:

• Keep all safety devices, air vents and the motor housing free of dirt and dust

as far as possible. Wipe the equipment with a clean cloth or blow it with com-

pressed air at low pressure.

• We recommend that you clean the device immediately each time you have n-

ished using it.

• Clean the equipment regularly with a moist cloth and some soft soap. Do not

use cleaning agents or solvents; these could attack the plastic parts of the

equipment. Ensure that no water can seep into the device.

Carbon brushes

In case of excessive sparking, have the carbon brushes checked only by a qualied

electrician. Important! The carbon brushes should not be replaced by anyone but

a qualied electrician.

Check the oil level (Fig. 5)

Check the oil level before using the machine. Place the machine on the oor with the

tool mounting pointing downwards. The oil must be at least 3 mm above the bottom

edge of the inspection window (6). Changing the oil: The oil should be changed after

around 40-50 hours of use. Recommended oil: 25ml SAE 15W/40 or an alternative

of the same quality.

Oil change (Fig. 7)

Switch off the machine and pull the mains plug out of the socket.

Undo the hexagonal head screw with the inspection window (6) using the spanner

(9) and drain the oil. To prevent the oil from running out in an uncontrolled manner,

hold a small metal chute under the opening and collect the oil in a vessel until it has

fully drained out of the machine.

AFTER SALES SUPPORT 19

1300 855 831 support@scheppach.com.au

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

AB1600 Maintenance/Electrical connection

Important: The waste oil must be disposed of in the appropriate collection point for

waste oil. Add new oil (approx. 25 ml) through the oil ller opening (6) until the oil

level reaches the required level. Tighten the hexagonal screw again. Re-check the

oil level after a short period of operation.

X. ELECTRICAL CONNECTION

The electrical motor installed is connected and ready for operation. The

connection complies with the applicable Australian standards.

The customer‘s mains connection as well as the extension cable used must

also comply with these regulations.

Damaged electrical connection cable

The insulation on electrical connection cables is often damaged.

This may have the following causes:

• Passage points, where connection cables are passed through windows or

doors.

• Kinks where the connection cable has been improperly fastened or routed.

• Places where the connection cables have been cut due to being driven over.

• Insulation damage due to being ripped out of the wall outlet.

• Cracks due to the insulation ageing.

Such damaged electrical connection cables must not be used and are life-threat-

ening due to the insulation damage. Check the electrical connection cables for

damage regularly. Make sure that the power is switched off before inspecting the

cable. Electrical connection cables must comply with the applicable Australian

standards and must be correctly marked. Only use connection cables with the

marking ''H07RN-F''.Replacement cables can only be tted by an approved and

certied electrician. If you are in any doubt please contact the help line at the foot

of this page.

AC motor

• The mains voltage must be 230 - 240 V~.

• Extension cables up to 25 m long must have a cross-section of 1.5 mm2.

• The mains connection must be protected with a delay action fuse of 16 A.

Connections and repairs of electrical equipment may only be carried out by an

electrician.

Please provide the following information in the event of any enquiries:

• Type of current for the motor

• Machine data - type plate

20 AFTER SALES SUPPORT

support@scheppach.com.au 1300 855 831

MODEL: AB1600 PRODUCT CODE: 53670 08/2017

AUS

Disposal and Recycling/Troubleshooting AB1600

XI. DISPOSAL AND RECYCLING

The equipment is supplied in packaging to prevent it from being damaged in

transit. The raw materials in this packaging can be reused or recycled. The

equipment and its accessories are made of various types of material, such as

metal and plastic. Defective components must be disposed of as special waste.

Ask your dealer or your local council.

XII. TROUBLESHOOTING

Problem Possible Cause Help

Motor does not

start

a) Failure of mains fuse a) Check the mains fuse

b) Extension cable defec-

tive

b) Replace defective extension

cable

c) Connections at the mo-

tor or switch out of order

c) Check with the help of an elec-

trician

d) Motor or switch defective d) Check with the help of an

electrician

Motor does not

work, the fuse

responds

a) Cross section of the ex-

tension cable insufciently

a) Refer to Electrical Connection

b) Overload b) Check tool

5

DEMOLITION BREAKER

Warranty Details

The product is guaranteed to be free from defects in workmanship and parts for a period

of 60 months from the date of purchase. Defects that occur within this warranty period,

under normal use and care, will be repaired, replaced or refunded at our discretion.

The benets conferred by this warranty are in addition to all rights and remedies in respect of

the product that the consumer has under the Competition and Consumer Act 2010 and similar

state and territory laws.

Our goods come with guarantees that cannot be excluded under the Australian Consumer

Law. You are entitled to a replacement or refund for a major failure and for compensation

for any other reasonably foreseeable loss or damage. You are also entitled to have the goods

repaired or replaced if the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

AFTER SALES SUPPORT

1300 855 831 support@scheppach.com.au

AUS Hotline Costs MODEL:DH1300PLUS PRODUCT CODE: 53670 08/2017

5

REGISTER YOUR PURCHASE AT www.aldi.com.au/en/about-aldi/product-registration/ TO KEEP UP-TO-DATE WITH IMPORTANT PRODUCT INFORMATION

DEMOLITION BREAKER

Repair and Refurbished Goods

or Parts Notice

Unfortunately, from time to time, faulty products are manufactured which need to be returned

to the Supplier for repair.

Please be aware that if your product is capable of retaining user-generated data (such as les

stored on a computer hard drive, telephone numbers stored on a mobile telephone, songs

stored on a portable media player, games saved on a games console or les stored on a USB

memory stick) during the process of repair, some or all of your stored data may be lost.

We recommend you save this data elsewhere prior to sending the product for repair.

You should also be aware that rather than repairing goods, we may replace them with

refurbished goods of the same type or use refurbished parts in the repair process.

Please be assured though, refurbished parts or replacements are only used where they

meet ALDI’s stringent quality specications.

If at any time you feel your repair is being handled unsatisfactorily, you may escalate your

complaint. Please telephone us on 1300 855 831 or write to us at:

RossMac Pty. Ltd.

P.O. Box 261, Essendon North, Victoria, 3041

1300 855 831

support@scheppach.com.au

AFTER SALES SUPPORT

1300 855 831 support@scheppach.com.au

MODEL:AB1600 PRODUCT CODE: 53670 08/2017

5

Table of contents

Other Workzone Power Tools manuals

Workzone

Workzone HS-060A-2 User manual

Workzone

Workzone WBJ-900 Operation instructions

Workzone

Workzone WMW 300-1 User manual

Workzone

Workzone WOT-280 Operation instructions

Workzone

Workzone DP17L User manual

Workzone

Workzone CGN300A User manual

Workzone

Workzone WMW 300-2 Product information sheet

Workzone

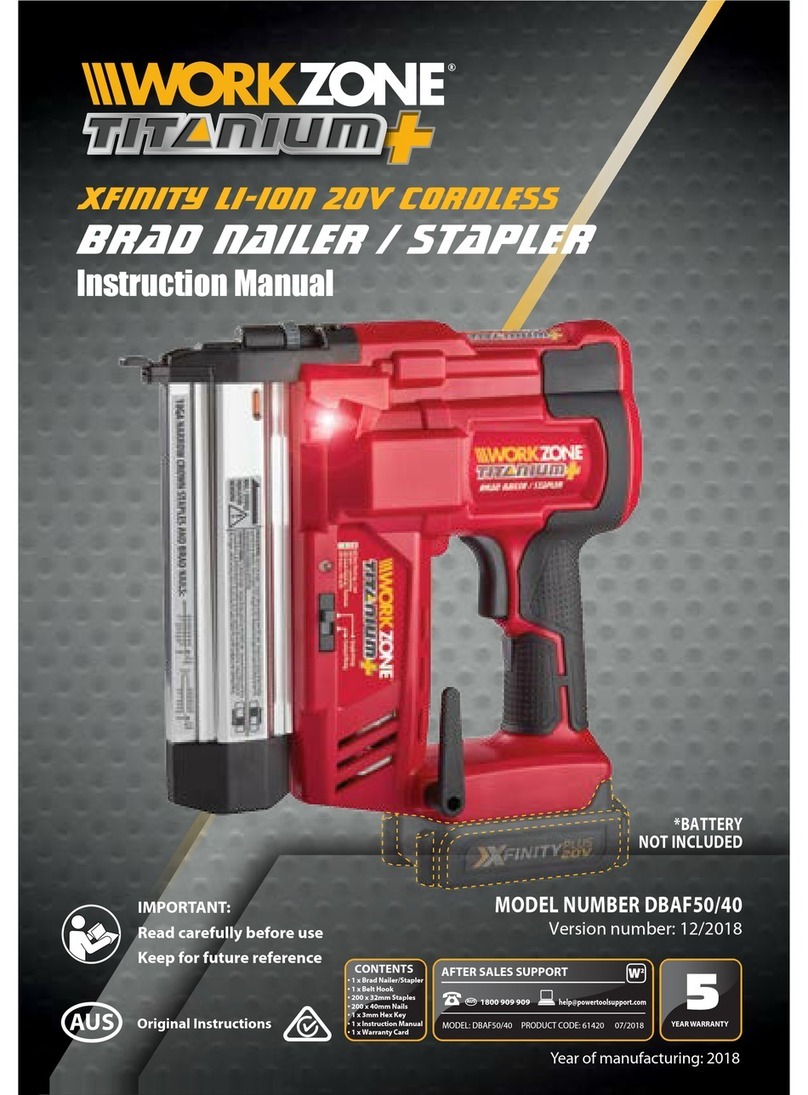

Workzone Titanium DBAF50/40 User manual

Workzone

Workzone WOC-1013 Operation instructions

Workzone

Workzone BT-CK 18 Li User manual