Welding sparks can cause fire or explosion.

■ Remove fire hazards from the welding area. If this is not possible, cover them to prevent the

welding sparks from starting a fire. Remember that welding sparks and hot materials from welding

can easily go through small cracks and opening to adjacent areas. Avoid welding near hydraulic

lines.

■ When not welding, make certain no part of the electrode circuit is touching the work or ground.

Accidental contact can cause overheating and create a fire hazard.

■ Do not weld on drums, tanks, or any closed containers unless a qualified person has tested it and

declared it or prepared it to be safe.

■ Connect the work cable to the work as close to the welding area as practical. Work cables

connected to the building framework or other locations away from the welding area increase the

possibility of the welding current passing through lifting chains, crane cables or other alternate

circuits. This can create fire hazards or overheat lifting chains or cables until they fail.

■ INSTALLATION

● The welding machine shall be installed at a place ;

free from the inflammables

less humidity, dirt and dust

protecting from influence of direct sunlight, wind and rain

not generated oil vapor and corrosive gas

operating temperature range is from -10℃ to 40℃

least 30㎝ away from wall and other welding machine

● Input Connection (Rear of the machine)

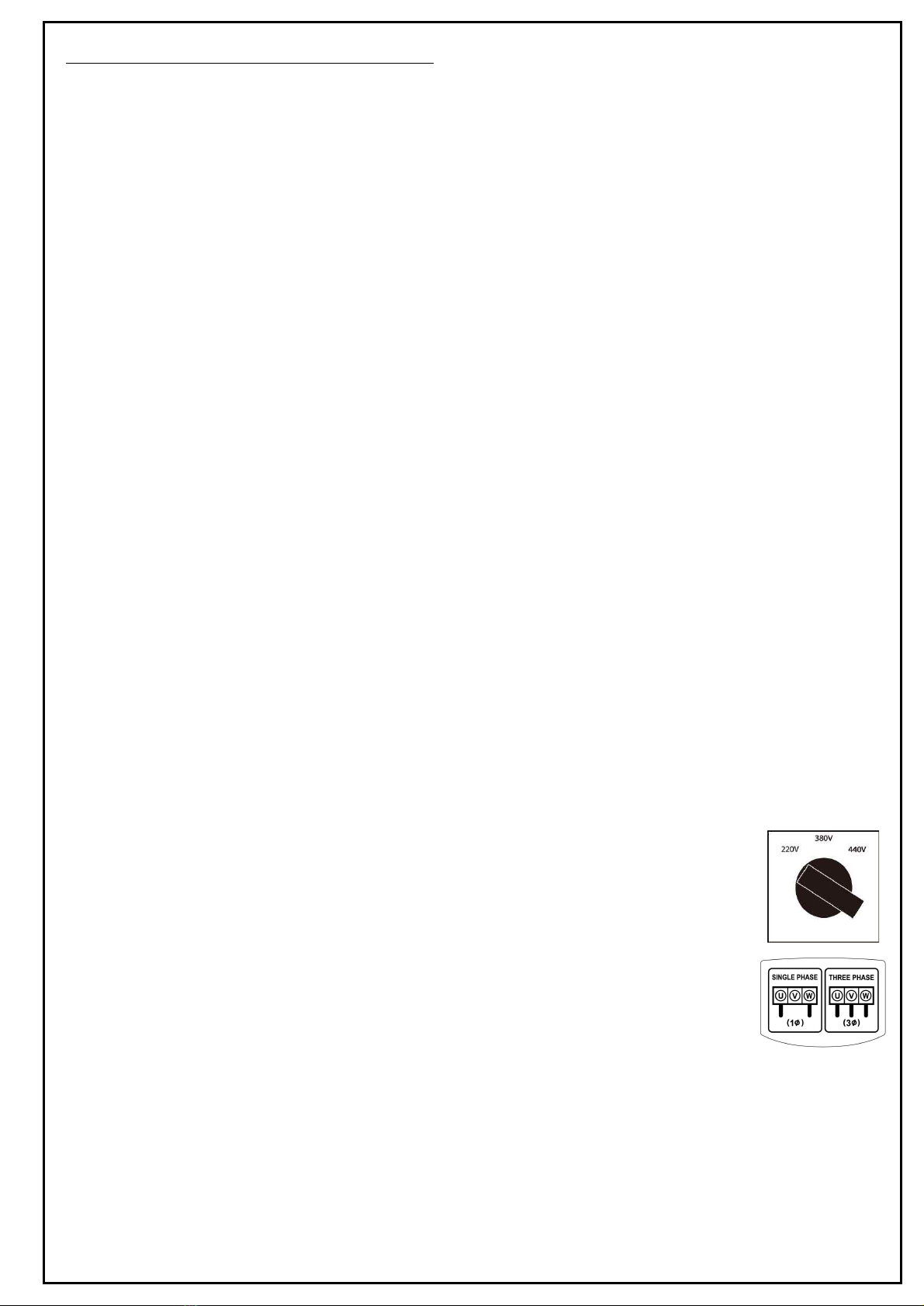

Be sure the voltage, phase and frequency of the input power is as specified on the name plate

located on the rear panel of the machine.

To connect the power cables, turn the power switch OFF

Verify the voltage to be supplied from main power.

Verify the connection of voltage selection switch. If necessary to change it, remove the

cover of voltage selection switch and turn the switch to correct voltage to be

supplied from main power. Close the cover.

Open the cover of terminal and connect the power cable to the power input terminal on

the rear of the machine and close the cover of terminal. For grounding the machine,

connect a ground wire to the ground terminal marked with the symbol is located on the

rear panel of the machine.

Connect a power cord of gas regulator to the 110V outlet on rear of the machine.

● Output Connection (Front of the machine)

Connect the work cable to the "METAL" terminal.

To connect the Wire feeder, connect a electrode cable from wire feeder to the "TORCH" terminal and

a Remote control cable from the wire feeder to the "REMOTE CONTROL" receptacle.

Install a gas regulator on a gas tank and connect a gas hose of extension cable from wire feeder to the

gas regulator on gas tank.