2

30-10001669

Table of Contents

Important Warnings……………………………………………………………………………………………………...3

Description .........................................................................................................................................................4

Features and Functions.....................................................................................................................................5

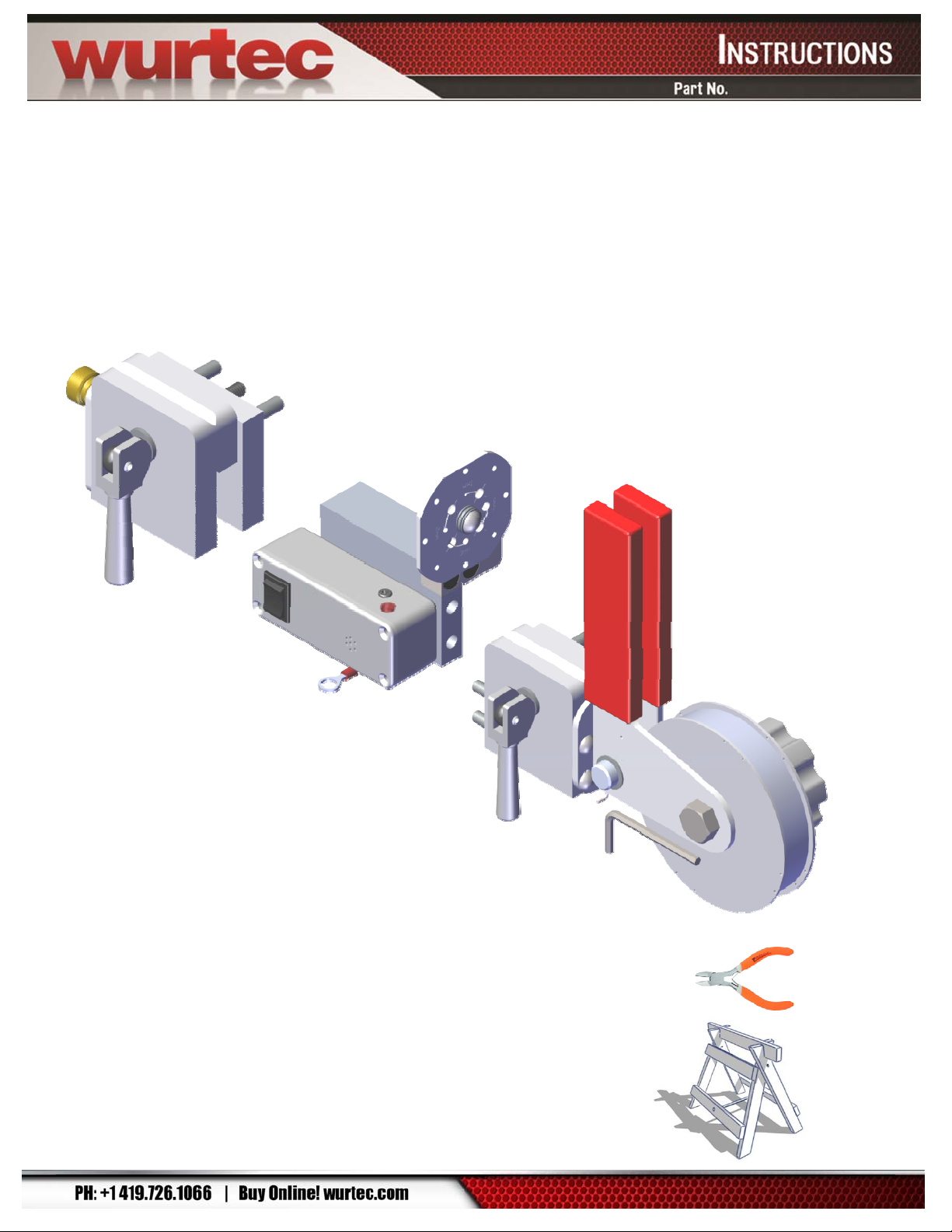

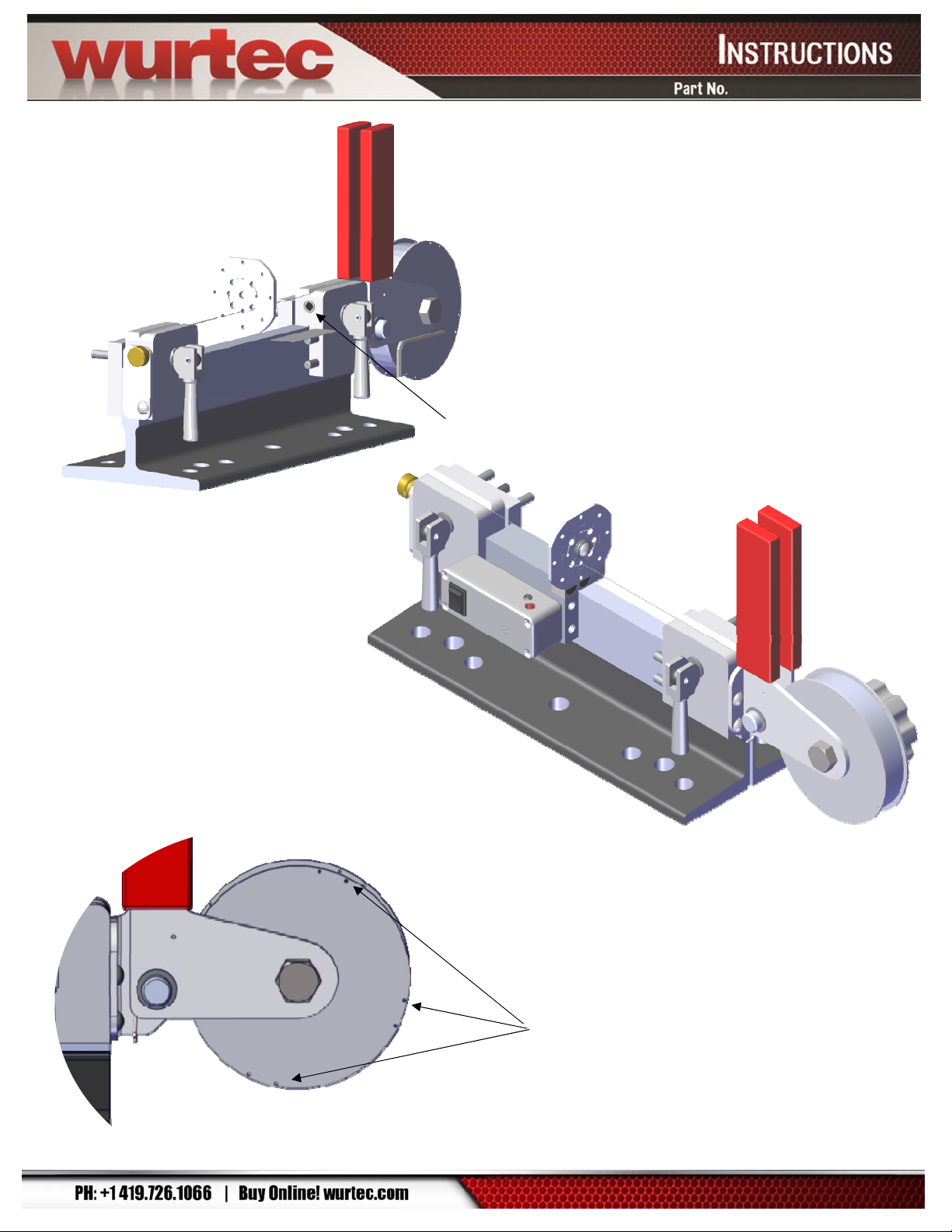

Set Up..................................................................................................................................................................9

1. Rail Set Up ...............................................................................................................................................9

2. Rail Straightness Tester Set Up.............................................................................................................9

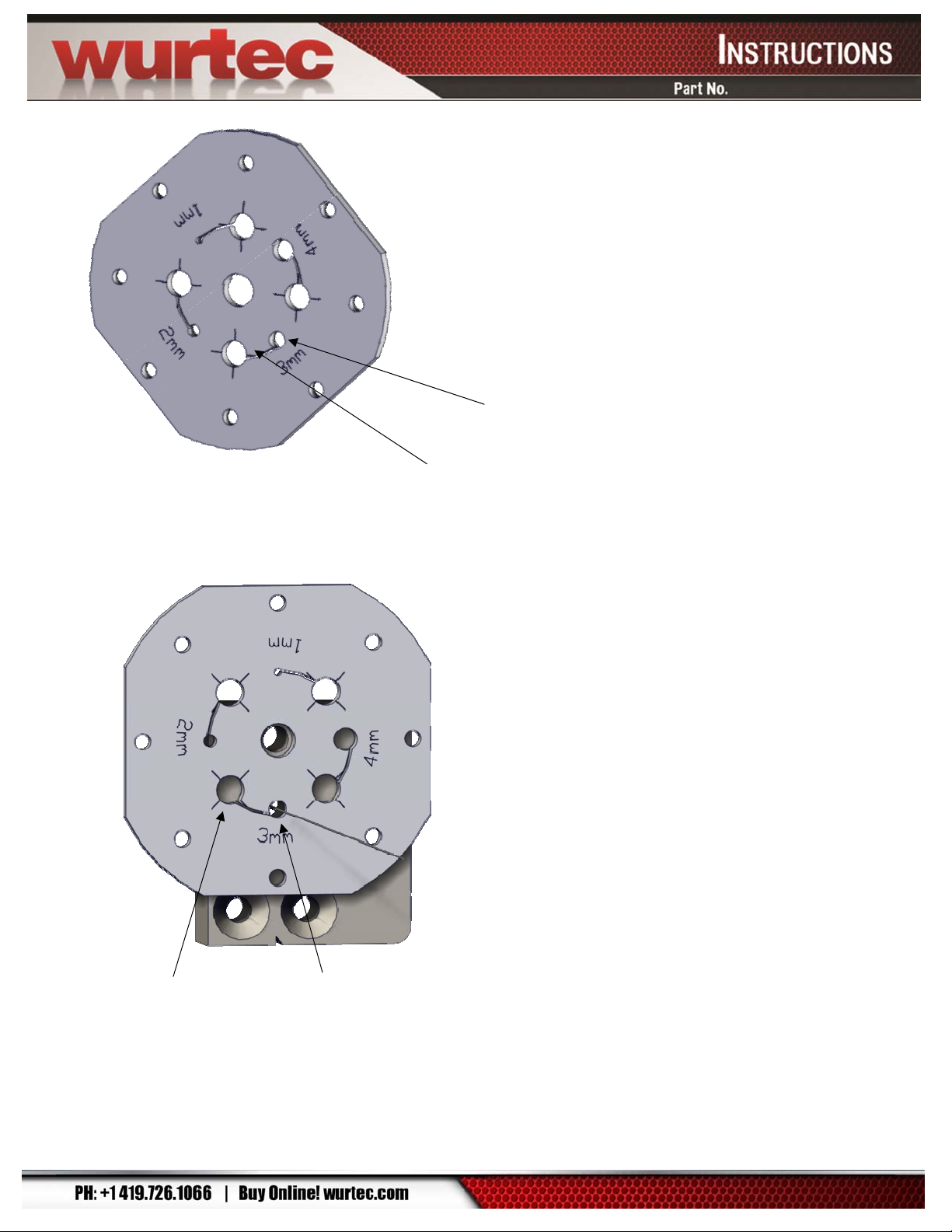

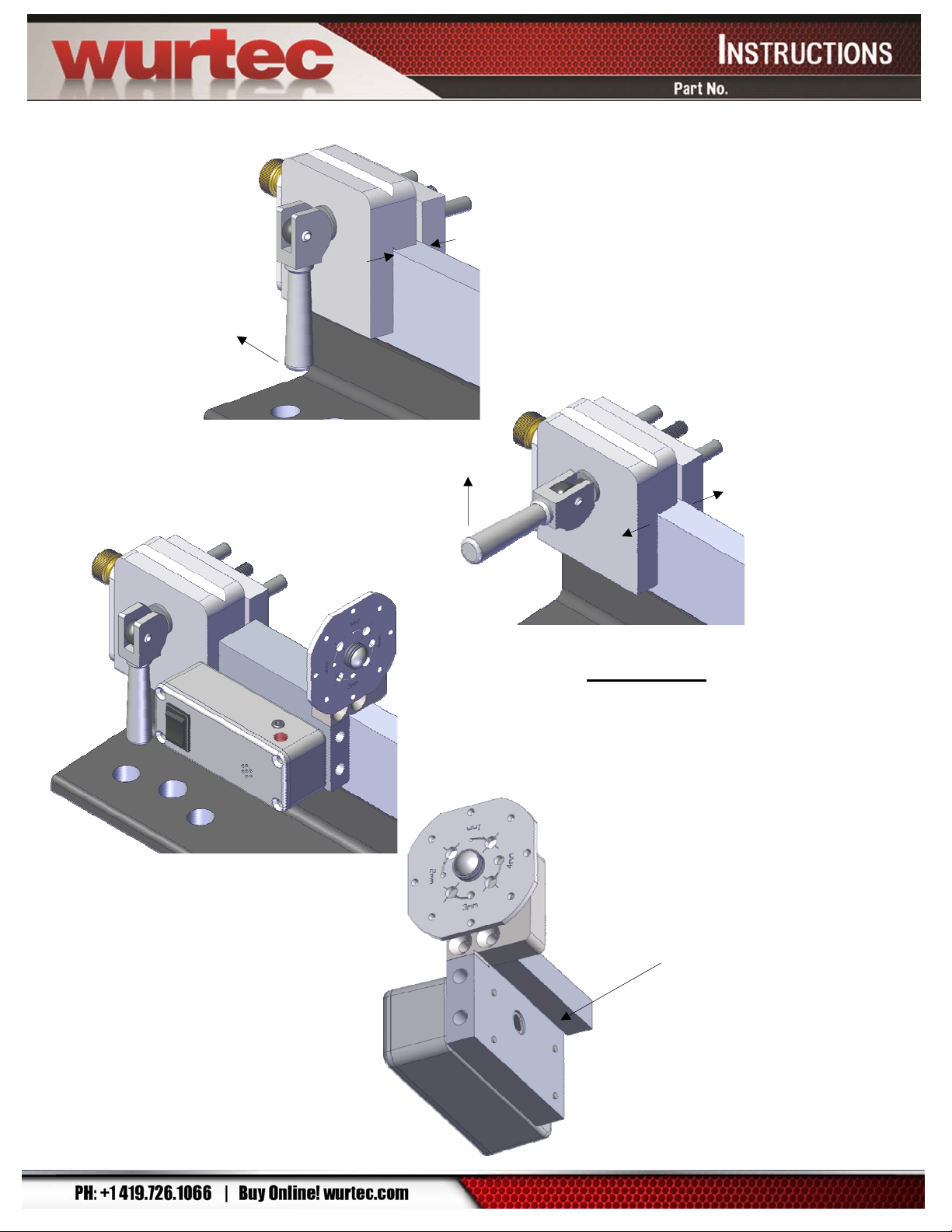

a. Rail End Clamp...............................................................................................................................10

c. Rail End Clamp (with Spool Assembly) .......................................................................................11

d. Steel Wire Installation....................................................................................................................11

Testing and Operation.....................................................................................................................................13

Troubleshooting...............................................................................................................................................14

Replacement Parts.......................................................................................................................................14

Bill of Materials.................................................................................................................................................15

Rail End Clamp 30-10001686...........................................................................................................................15

Exploded View..........................................................................................................................................15

Parts List...................................................................................................................................................15

Sensor Block 30-10001673..............................................................................................................................16

Exploded View..........................................................................................................................................16

Parts List...................................................................................................................................................16

Rail End Clamp 30-10001698...........................................................................................................................17

Exploded View..........................................................................................................................................17

Parts List...................................................................................................................................................18