EC-WS10

EC-DWS10 <With digital speed controller>

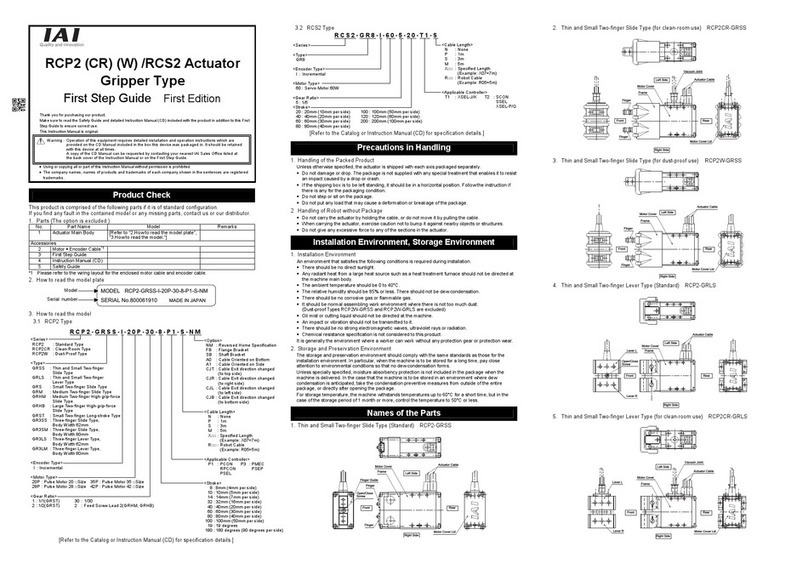

■Model Specification Items

EC - - - -

Series - Type Lead - Stroke - Power • I/O cable length - Options

WS10 Standard S20mm 50 50mm See power • I/O cable length

below

See options

below

DWS10 Digital speed controller H12mm

~

~

M6mm 500 500mm

L3mm (Every 50mm)

デジタルスピコン

■Stroke

Stroke

(mm) WS10 DWS10 Stroke

(mm) WS10 DWS10

50 300

100 350

150 400

200 450

250 500

Selection

Notes

(1) The maximum speed decreases as the stroke becomes longer

due to the dangerous number of rotation of the ball screw.

Confirm the maximum speed, referring to the “Stroke and Max.

Speed” of the desired stroke.

(2) “Main Specifications” displays the payload’s maximum value. If

the energy-saving setting is enabled, the main specifications will

change. Please refer to “Table of Payload by Speed/Acceleration”

for details.

(3) If performing push-motion operations, refer to the“Correlation

between Torque and Current Limit” diagram. The torques listed

are only reference values. Refer to P. 26 for precautions.

(4) Pay close attention to the installation orientation.

Please refer to P. 5 for details.

(5) The “H” and “S” leads cannot be vertically mounted.

(6) Reference value of the overhang load length is under 400mm in

the Ma, Mb, and Mc directions. Refer to descriptions about the

overhang length on P. 5.

(7) The center of gravity of the attached object should be less than

1/2 of the overhang distance. Even when the overhang distance

and load moment are within the allowable range, the operating

conditions should be moderated if some abnormal vibration or

noise is observed.

■Options

Name Option code

Reference page

RCON-EC connection specification (Note 1) ACR 23

Brake B23

Air cylinder mounting plate CS 23

Digital speed controller installation direction (left) (Note 2)

DL 24

Digital speed controller installation direction (right) (Note 2)

DR 24

Designated grease specification

(Note 3)

G1/G5 25

Non-motor end specification NM 25

PNP specification PN 25

Slider part roller specification SR 25

Split motor and controller power supply specification TMD2 25

Battery-less

absolute encoder specification WA 25

Wireless communication specification WL 25

Wireless axis operation specification WL2 25

(Note 1) If the RCON-EC connection specification (ACR) is selected, the PNP specification

(PN) and split motor and controller power supply specification (TMD2) cannot be

selected.

(Note 2) Available only for DWS10. Be sure to enter a model in the options section of the

model number.

(Note 3) When using Lead 3 in a vertical mount, the max. speed is 110mm/s if the

specified grease specification (G1) is selected.

■Power · I/O cable length

■Standard connector cable

Cable code Cable

length

User wiring specification

(flying leads)

RCON-EC connection specification (Note 5)

(with connectors on both ends)

CB-EC-PWBIO£££-RB

supplied

CB-REC-PWBIO£££-RB

supplied

0No cable (Note 4)

1 ~ 3 1 ~ 3m

4 ~ 5 4 ~ 5m

6 ~ 7 6 ~ 7m

8 ~ 10 8 ~ 10m

(Note 4) Only terminal block connector is included. Please refer to P. 31 for details.

(Note 5) If RCON-EC connection specification (ACR) is selected as an option.

(Note) Robot cable is standard.

■4-way connector cable

Cable code Cable

length

User wiring specification

(flying leads)

RCON-EC connection specification (Note 6)

(with connectors on both ends)

CB-EC2-PWBIO£££-RB

supplied

CB-REC2-PWBIO£££-RB

supplied

S1 ~ S3 1 ~ 3m

S4 ~ S5 4 ~ 5m

S6 ~ S7 6 ~ 7m

S8 ~ S10 8 ~ 10m

(Note 6) If RCON-EC connection specification (ACR) is selected as an option.

(Note) Robot cable is standard.

24V

Stepper

Motor

Body Width

100

mm

Coupled

Motor

Simple

Dust-

proof

Horizontal

Side

Ceiling

EC-WS10/DWS10

Digital speed controller

EC-WS10 EC-DWS10

7

ECELECYLINDER®