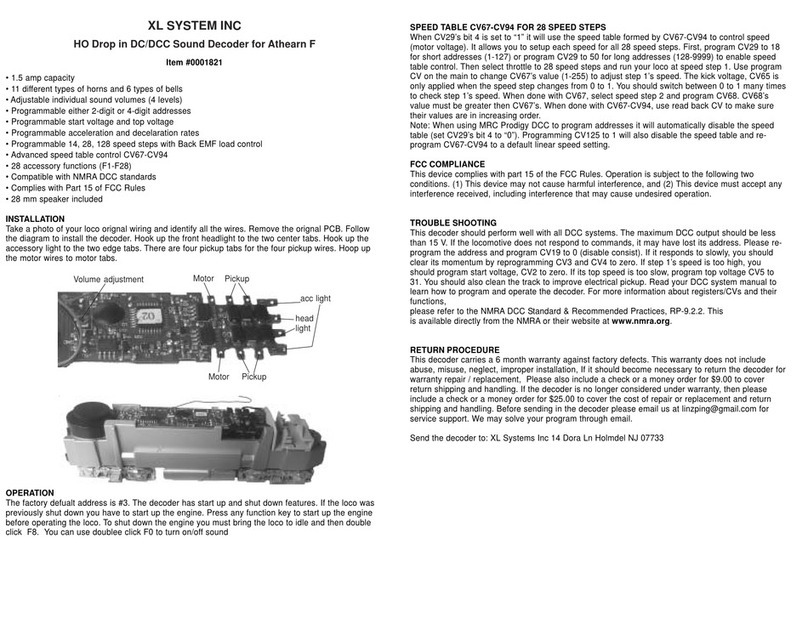

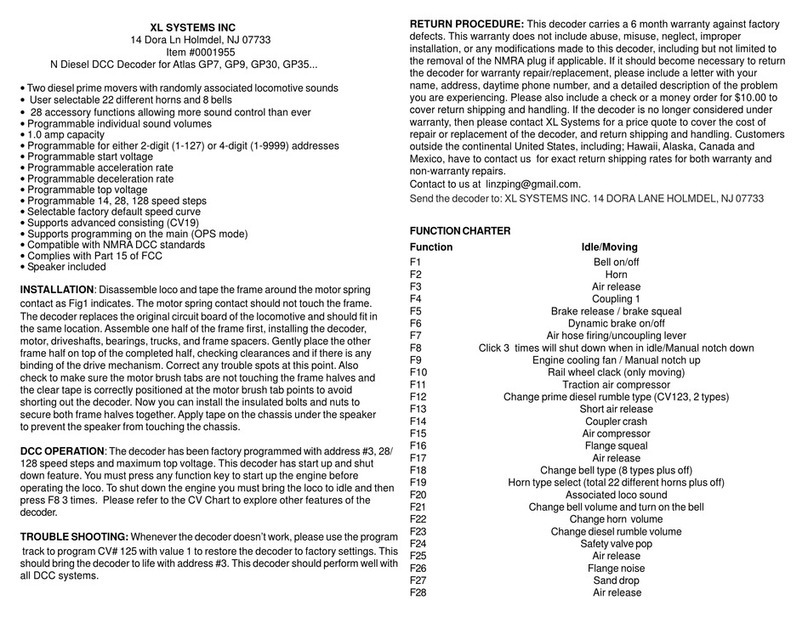

CV CHARTER

CV# Description Range defualt

CV1 Short address 1-127 3

CV2 Start voltage 0-63 10

CV3 Acceleration 0-63 0

CV4 Deceleration 0-63 0

CV5 Top voltage 0-63 63

CV29 Basic configuration 2

CV19 Advanced consist address 0-127 0

CV21 CV21=0, all accessory functions follow its own address. When CV21=1, all

functions will follow the consist address 0

CV49 Master volume control 16=max volume, 0=sound off 0-16 16

CV50 Horn type (22 types plus off, 22=off) 0-22 13

CV51 Horn volume 0-15 15

CV52 Bell type (8 types plus off, 8=off) 0-7 5

CV53 Bell volume 0-15 15

CV54 Bell ring rate 0-50 3

CV55 Diesel rumble volume 0-15 12

CV56 Brake squeal volume 0-15 12

CV57 Dynamic brake volume 0-15 12

CV58 Air release volume 0-15 12

CV59 Air pump volume 0-15 12

CV60 Safety pop valve volume 0-15 12

CV61 Engine cooling fan volume 0-15 12

CV62 Coupling volume 0-15 12

CV64 Rail wheel clack 0-15 12

CV65 Kick start voltage 0-63 63

CV67-9428 speed steps table while CV29.4=1 1-255

CV112 Back EMF start speed adjudstment 0-7 0

CV113 Back EMF load control proportional gain kp 0-31 20

CV114 Back EMF load control integral gain ki 0-31 10

CV115 Brake sound type: 2=breke sound off 0-2 0

CV117 Light brightness 0-15 0

CV120 Light brightness 0-255 255

CV121 Air compressor mode (1=change with engine rpm) 0-1 0

CV122 Diesel notch mode, 0=auto notch 3=manual notch 0-3 0

CV123 Diesel prime mover select 0-5 0

CV124 Back EMF load control intensity (0=off) 0-255 0

CV125 Program to “1” will restore some CV’s to factory settings …. 0

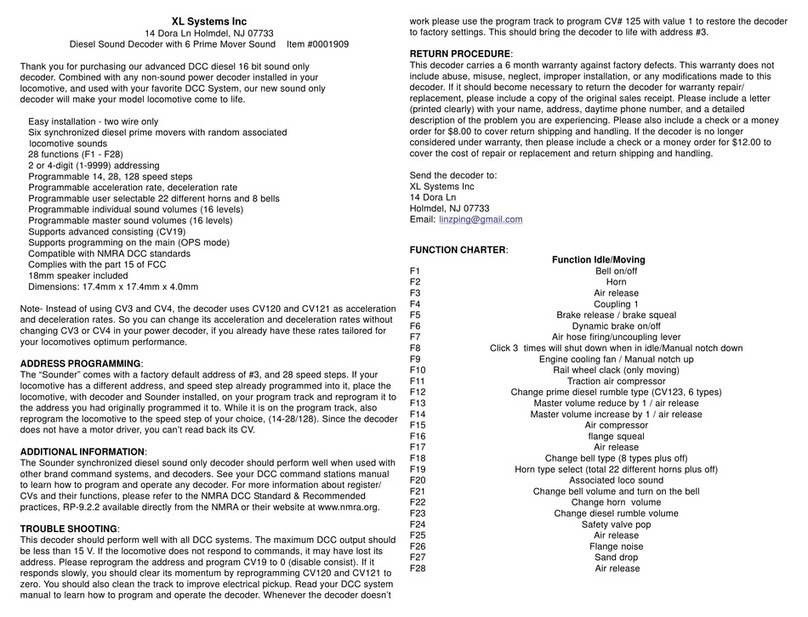

FUNCTION CHARTER

Function Idle/Moving

F1 Bell on/off

F2 Horn

F3 Air release

F4 Coupling 1

F5 Brake release / brake squeal

F6 Dynamic brake on/off

F7 Air hose firing/uncoupling lever

F8 Click 3 times will shut down when in idle/Manual notch down

F9 Engine cooling fan / Manual notch up

F10 Rail wheel clack (only moving)

F11 Traction air compressor

F12 Change prime diesel rumble type (CV123, 6 types)

F13 Master volume reduce by 1 / air release

F14 Master volume increase by 1 / air release

F15 Air compressor

F16 flange squeal

F17 Air release

F18 Change bell type (8 types plus off)

F19 Horn type select (total 22 different horns plus off)

F20 Associated loco sound

F21 Change bell volume (go up by 1 and back 0 when reach top)

F22 Change horn volume (go up by 1 and back 0 when reach top)

F23 Change diesel rumble volume(go up by 1 and back 0 when reach top)

F24 Safety valve pop

F25 Air release

F26 Flange noise

F27 Sand drop

F28 Air release

RETURN PROCEDURE

This decoder carries a 6 month warranty against factory defects. This warranty

does not include abuse, misuse, neglect, improper installation, or any modifications

made to this decoder, including but not limited to the removal of the NMRA plug if

applicable. If it should become necessary to return the decoder for warranty repair/

replacement, please include a letter with your name, address, daytime phone

number, and a detailed description of the problem you are experiencing. Please

also include a check or a money order for $9.00 to cover return shipping and

handling. If the decoder is no longer considered under warranty, then please contact

XL Systems for a price quote to cover the cost of repair or replacement of the

decoder, and return shipping and handling. Customers outside the continental

United States, including; Hawaii,Alaska, Canada and Mexico, have to contact us

for exact return shipping rates for both warranty and non-warranty repairs. Contact

Send the decoder to: XL SYSTEM INC. 14 DORA Lane HOLMDEL, NJ 07733

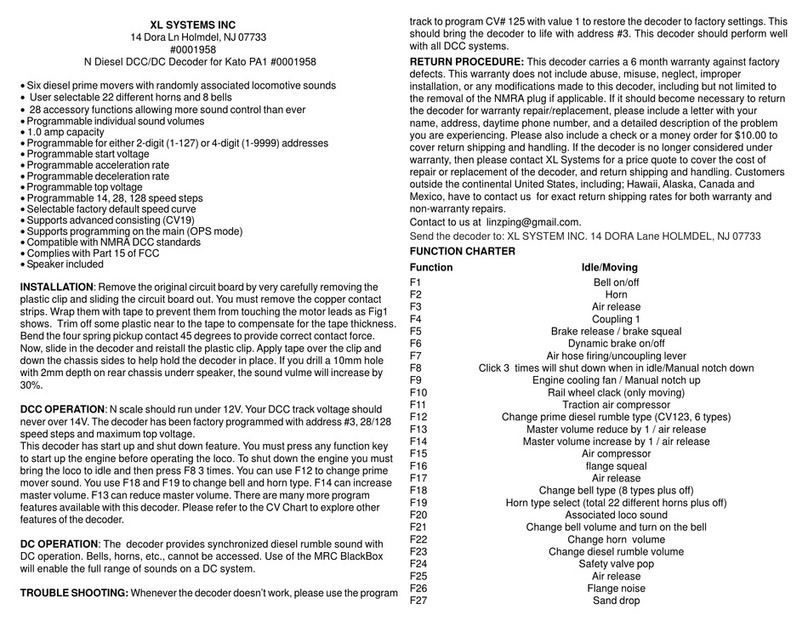

CV123 PRIME MOVER CHARTER

CV123 Prime mover Suitable for the locomotive

0 EMD645E SD39, SD40, SD40A, SD40-2, SD40T-2, SD45, SDP45, SD45X, SD45-2,

SD45T-2, F45, FP45, DDA40X, GP15T, GP39, GP39-2, GP40, GP40-2

1 EMD645 SW 1000, SW1001, SW1500, SW1500, SW1504, MP15DC, MP15AC,MP15T,

GP38, GP38-2, SD38, SD38-2, GP15AC, GP15-1

2 EMD710 SD70AC, SD70M-2

3 ALCO244 RS-3, PA1, PB1

4 ALCO539T S-2, S-4, RS-1, RSC-1, RSD-1, DL-105, DL-107, DL-108, DL-109, DL-110

5 EMD567 F2A/B, F3A/B, F7A/B, F9A/B, BL1, BL2, FP7, FL9, FT, GP7, GP9 ,GP,GP28

E6, E7, E8, E9, NW2, NW3, NW4, SW1, SW7, SW8, SW9, SW600, SW900