XL SYSTEMS INC

14 Dora Ln Holmdel, NJ 07733

Item #0001960

N Diesel DCC/DC Decoder for Kato SD70, AC4400 and more

• Two diesel prime movers with randomly associated locomotive sounds

•User selectable 22 different horns and 8 bells

•28 accessory functions allowing more sound control than ever

• Programmable individual sound volumes

• 1.0 amp capacity

• Programmable for either 2-digit (1-127) or 4-digit (1-9999) addresses

• Programmable start voltage

• Programmable acceleration rate

• Programmable deceleration rate

• Programmable top voltage

• Programmable 14, 28, 128 speed steps

• Selectable factory default speed curve

• Supports advanced consisting (CV19)

• Supports programming on the main (OPS mode)

• Compatible with NMRADCC standards

• Complies with Part 15 of FCC

• Speaker included

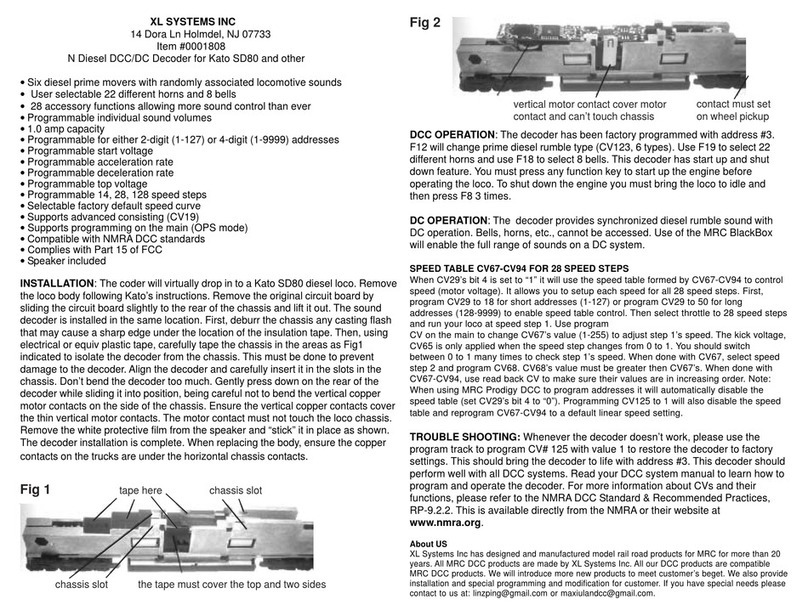

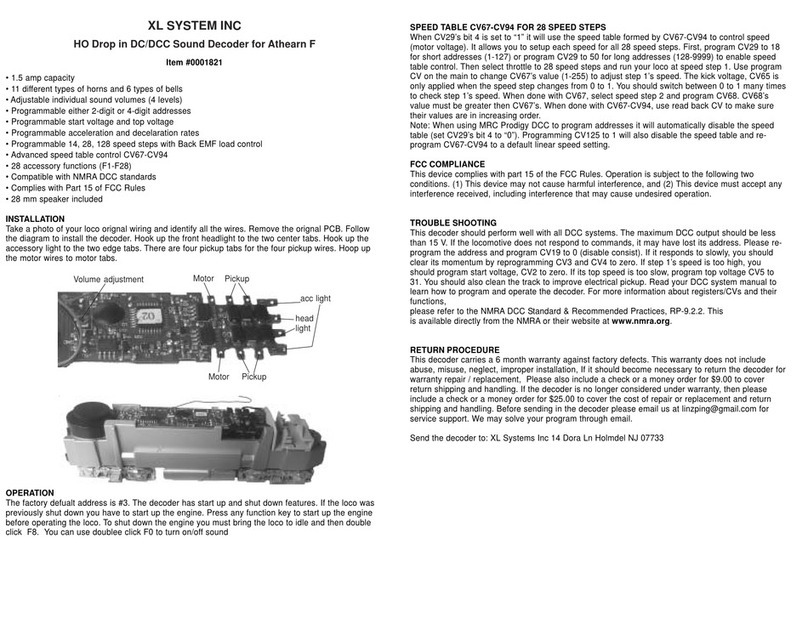

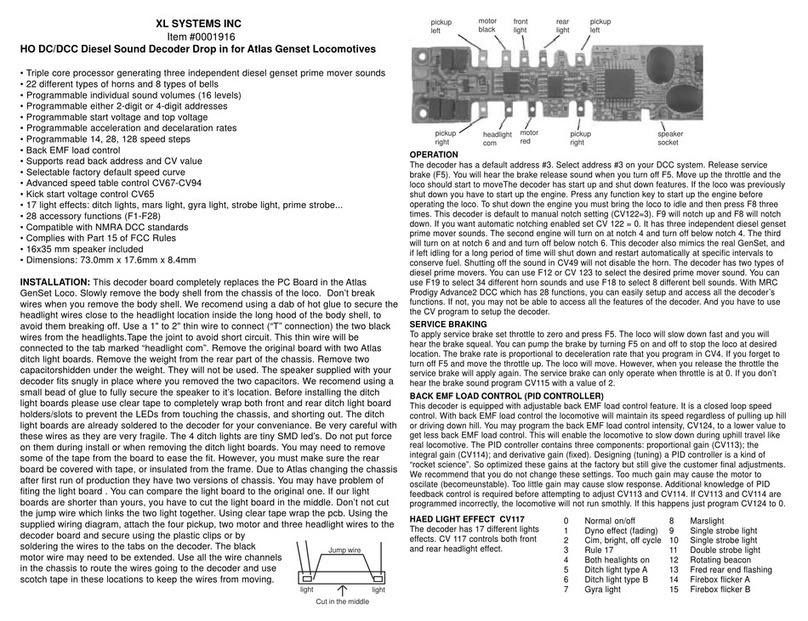

INSTALLATION: This Decoder will drop in Kato SD70 diesel loco.Although easy,

please follow instructions carefully. Remove two motor contact tabs attached to the

original PCB. Remove these two tabs and set aside, you will need to install them on

the decoder board in the same location. Lift and slide out the Kato PCB . Using

electrical or equiv plastic tape, carefully tape the chassis in the areas as indicated

(See fig 1 & 2) to isolate the decoder from the chassis. This must be done to

prevent damage to the decoder due to a short circuit between chassis halves and

the decoder. Any part of the decoder except the four pickup tabs touching chassis

will damage the decoder. Align the decoder and carefully insert it in the slots in the

chassis. Gently press down on the rear (speaker side) of the decoder while sliding it

into position. Don’t bend the decoder too much. Bending too much will damage the

decoder. Re-install the motor contacts tabs. Ensure the vertical brass contacts (on

the decoder) cover the thin vertical motor contacts.The motor, and decoder

contacts must not touch the loco chassis.

OPERATION: The decoder has been factory programmed with address #3.

Release service brake (F5) and dynamic brake (F6). You will hear the brake release

sound when you turn off F5. Move up the throttle and the loco should start to move.

This decoder has start up and shut down feature. You must press any function key

to start up the engine before operating the loco. To shut down the engine you must

bring the loco to idle and then press F8 3 times. There are many more program

features available with this decoder. Please refer to the CV Chart to explore other

features of the decoder. You can use F19 to select 22 different horns and use F18

to select 8 different bells. F12 will toggle between max master volume and sound

off. F13 willr reduce the master volume reduce by 1. F14 will increase the master

volume by 1. You can program CV122 to 3 for manual notch for realistic operation.

And then use F9 to notch up and use F8 to notch down.

FUNCTION CHARTER

Function Idle/Moving

F1 Bell on/off

F2 Horn

F3 Air release

F4 Coupling 1

F5 Brake release / brake squeal

F6 Dynamic brake on/off

F7 Air hose firing/uncoupling lever

F8 Click 3 times will shut down when in idle/Manual notch down

F9 Engine cooling fan / Manual notch up

F10 Rail wheel clack (only moving)

F11 Traction air compressor

F12 toggle between maximum master volume and sound off

F13 Master volume reduce by 1 / air release

F14 Master volume increase by 1 / air release

F15 Air compressor

F16 flange squeal

F17 Air release

F18 Change bell type (8 types plus off)

F19 Horn type select (total 22 different horns plus off)

F20 Associated loco sound

F21 Change bell volume and turn on the bell

F22 Change horn volume

F23 Change diesel rumble volume

F24 Safety valve pop

F25 Air release

F26 Flange noise

F27 Sand drop

F28 Air release

SERVICE BRAKING

To apply service brake set throttle to zero and press F5. The loco will slow down

fast and you will hear the brake squeal. You can pump the brake by turning F5 on

and off to stop the loco at desired location. The brake rate is proportional to

deceleration rate that you program in CV4. If you forget to turn off F5 and move the

throttle up. The loco will move. However, when you release the throttle the service

brake will apply again. The service brake can only operate when throttle is at 0. If

you don’t hear the brake sound program CV115 with a value of 2.

DYNAMIC BRAKING

You can use dynamic brake F6 to reduce the speed. When you turn on F6 the

prime mover will notch down to 1 and you will hear the dynamic brake sound and

the loco will reduce its speed. When you release F6 the loco will speed up to the

orignal speed. If you forget to turn off F6 and move throttle up it will automatically

disable the dynamic brake and loco will start to move. To apply the dynamic brake

again you have to cycle F6 off and on.