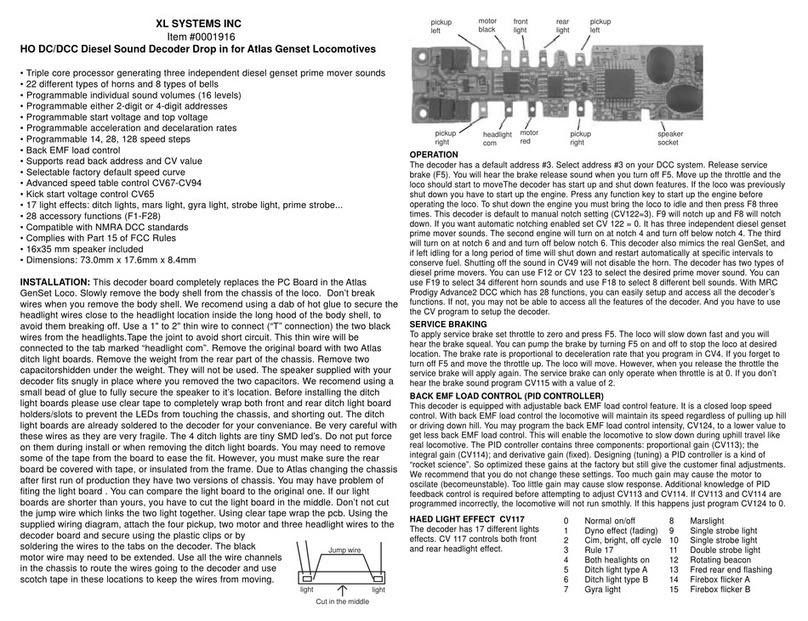

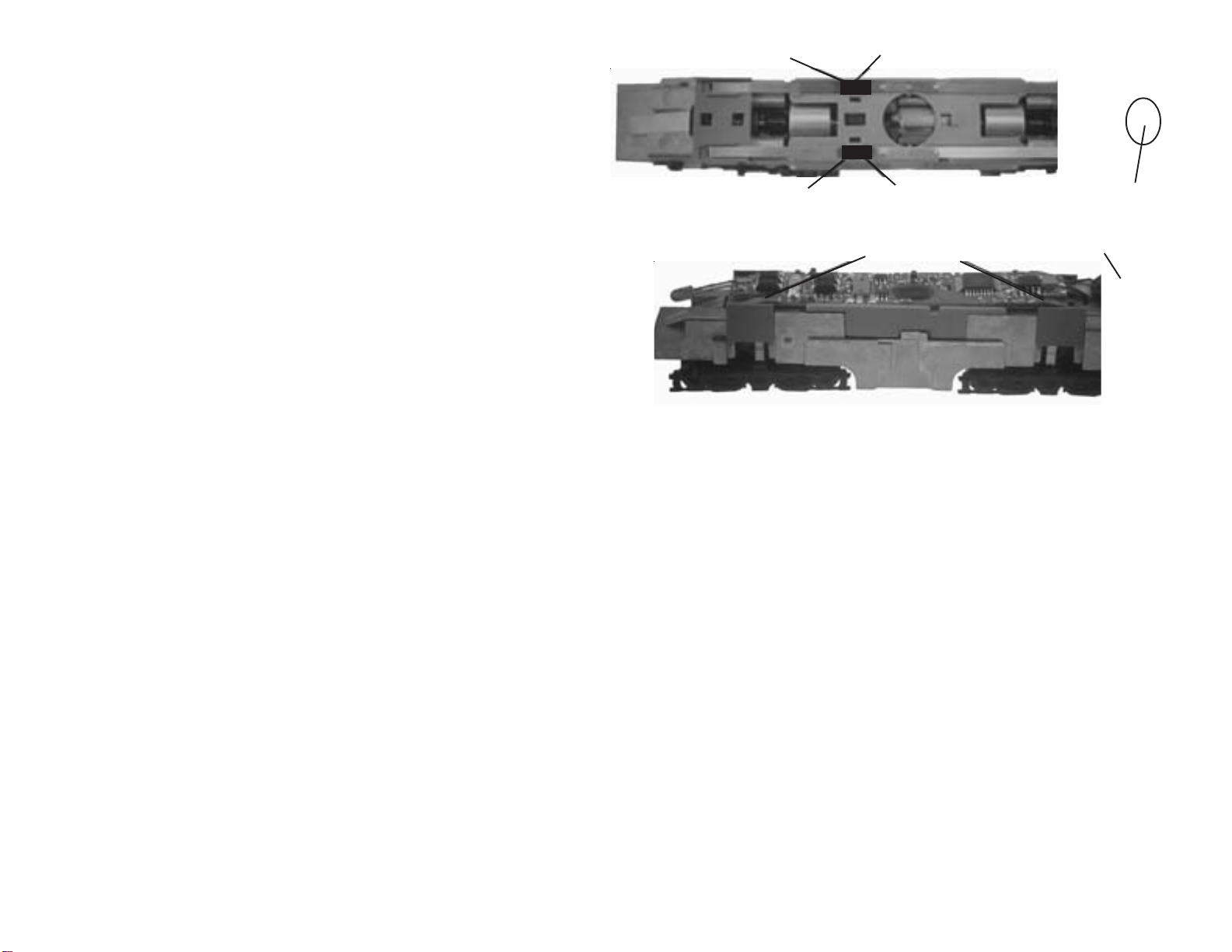

Trim off some plastic Wrap tape

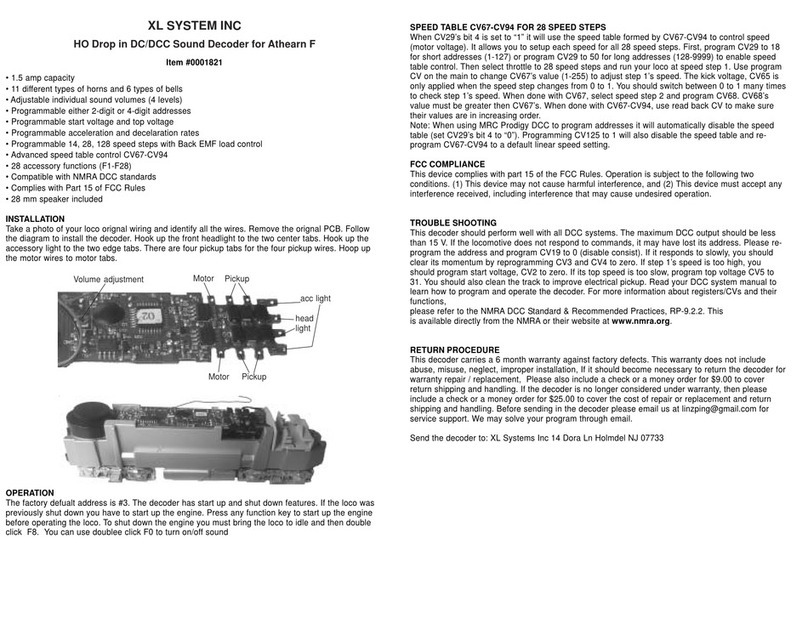

Fig 1

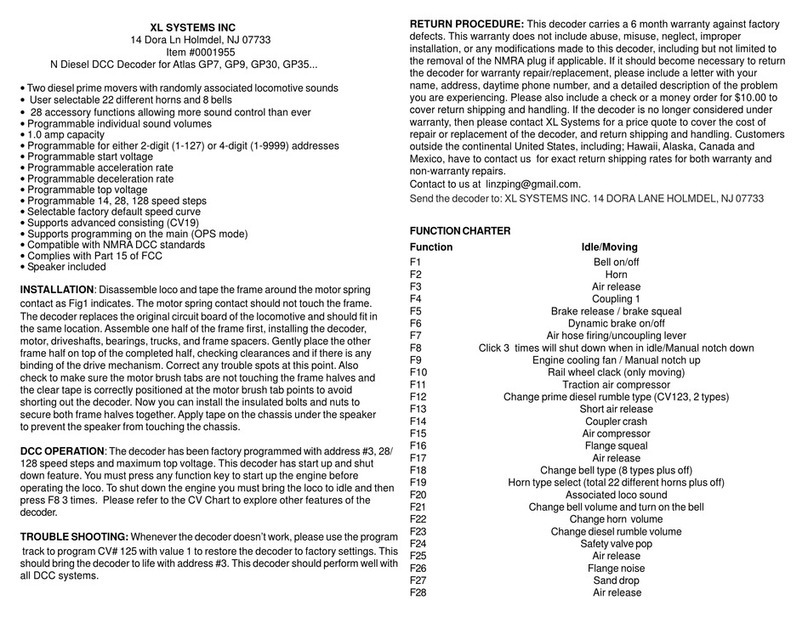

CV CHARTER

CV# Description Range Default

CV1 Short address 1-127 3

CV2 Start voltage 0-63 10

CV3 Acceleration 0-63 0

CV4 Deceleration 0-63 0

CV5 Top voltage 0-63 63

CV29 Basic configuration 2

CV19 Advanced consist address 0-127 0

CV21 CV21=0, all accessory functions follow its own address. When CV21=1, all

functions will follow the consist address 0

CV49 Master volume control 16=max volume, 0=sound off 0-16 16

CV50 Horn type (22 types plus off, 22=off) 0-22 13

CV51 Horn volume 0-15 15

CV52 Bell type (8 types plus off, 8=off) 0-7 5

CV53 Bell volume 0-15 15

CV54 Bell ring rate 0-50 3

CV55 Diesel rumble volume 0-15 12

CV56 Brake squeal volume 0-15 12

CV57 Dynamic brake volume 0-15 12

CV58 Air release volume 0-15 12

CV59 Air pump volume 0-15 12

CV60 Safety pop valve volume 0-15 12

CV61 Engine cooling fan volume 0-15 12

CV62 Coupling volume 0-15 12

CV64 Rail wheel clack 0-15 12

CV65 Kick start voltage 0-63 63

CV67-9428 speed steps table while CV29.4=1 1-255

CV112 Sand dropping sound volume 0-7 0

CV113 Back EMF load control proportional gain kp 0-31 20

CV114 Back EMF load control integral gain ki 0-31 10

CV115 Auto brake squeal enable/disable 0-1 1

CV116 Flange squeal volume 0-15 0

CV117 Light brightness 0-255 255

CV121 Air compressor mode (1=change with engine rpm) 0-1 0

CV122 Diesel notch mode, 0=auto notch 3=manual notch 0-3 0

CV123 Diesel prime mover select 0-5 0

CV124 Back EMF load control intensity (0=off) 0-255 0

CV125 Program to “1” will restore some CV’s to factory settings …. 0

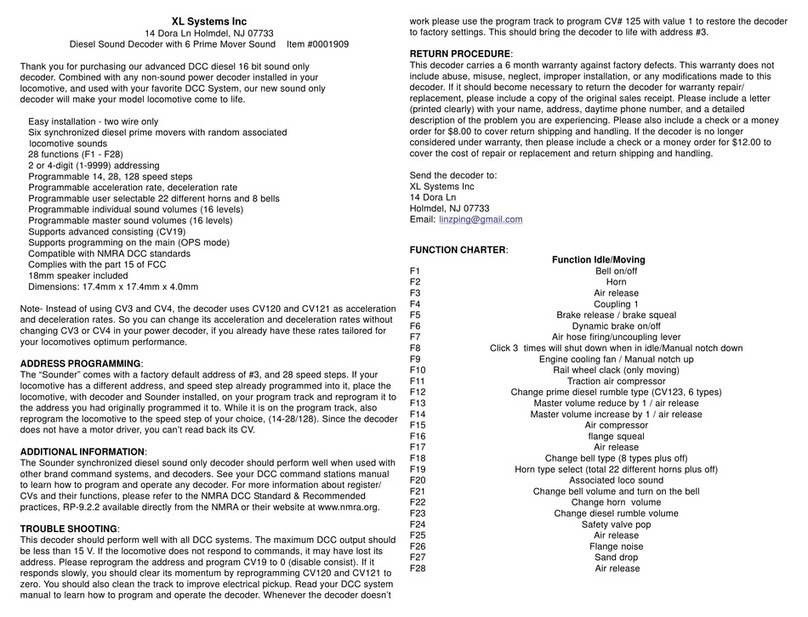

FCC COMPLIANCE

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions. (1) This device may not cause harmful interference, and (2) This device must accept any

interference received, including interference that may cause undesired operation.

About US

XL Systems Inc has designed and manufactured model rail road products for MRC for more than 20

years. All MRC DCC products are made by XL Systems Inc. All our DCC products are compatible

MRC DCC products. We will introduce more new products to meet customer’s beget. We also

provide installation and special programming and modification for customer. If you have special

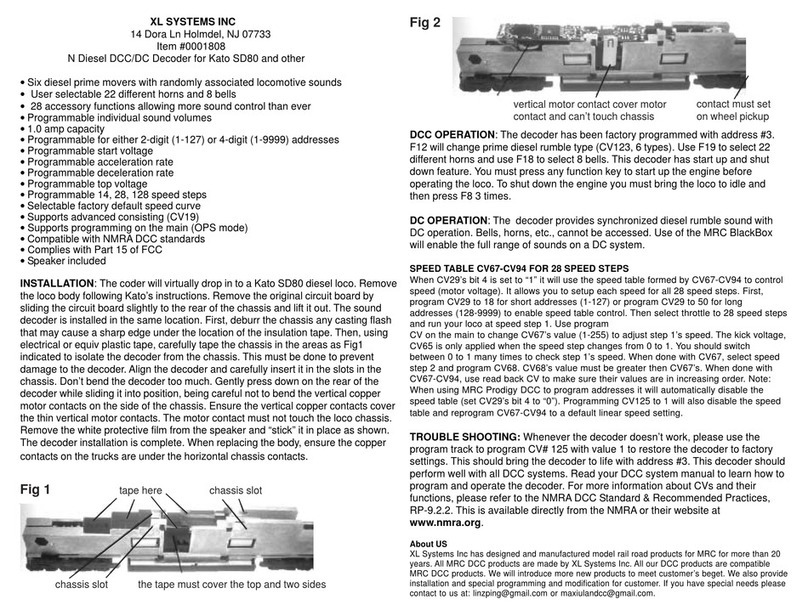

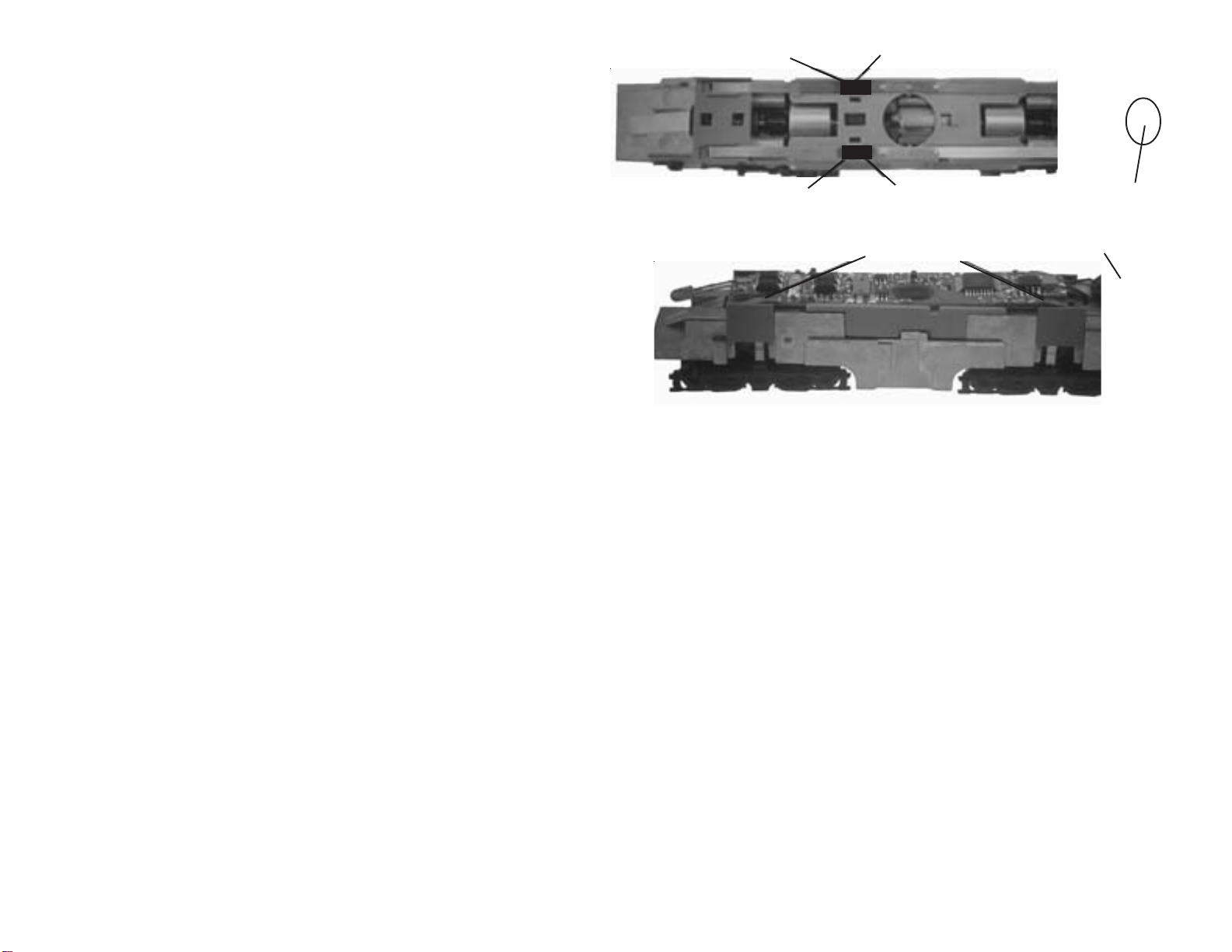

Fig 2 Bend spring pickup contacts Speaker

Trim off some plastic Wrap tape Option: drill 10mm x 2mm hole

SPEED TABLE CV67-CV94 FOR 28 SPEED STEPS

When CV29’s bit 4 is set to “1” it will use the speed table formed by CV67-CV94 to control speed

(motor voltage). It allows you to setup each speed for all 28 speed steps. First, program CV29 to

18 for short addresses (1-127) or program CV29 to 50 for long addresses (128-9999) to enable

speed table control. Then select throttle to 28 speed steps and run your loco at speed step 1. Use

program

CV on the main to change CV67’s value (1-255) to adjust step 1’s speed. The kick voltage, CV65

is only applied when the speed step changes from 0 to 1. You should switch between 0 to 1

many times to check step 1’s speed. When done with CV67, select speed step 2 and program

CV68. CV68’s value must be greater then CV67’s. When done with CV67-CV94, use read back

CV to make sure their values are in increasing order.

Note: When using MRC Prodigy DCC to program addresses it will automatically disable the speed

table (set CV29’s bit 4 to “0”). Programming CV125 to 1 will also disable the speed table and re-

program CV67-CV94 to a default linear speed setting.

CV123PRIMEMOVERCHARTER

CV123 Prime mover Suitable for the locomotive

0 EMD645E SD39, SD40, SD40A, SD40-2, SD40T-2, SD45, SDP45, SD45X, SD45-2,

SD45T-2, F45, FP45, DDA40X, GP15T, GP39, GP39-2, GP40, GP40-2

1 EMD645 SW 1000, SW1001, SW1500, SW1500, SW1504, MP15DC, MP15AC,MP15T,

GP38, GP38-2, SD38, SD38-2, GP15AC, GP15-1

2 EMD710 SD70AC, SD70M-2

3 ALCO244 RS-3, PA1, PB1

4 ALCO539T S-2, S-4, RS-1, RSC-1, RSD-1, DL-105, DL-107, DL-108, DL-109, DL-110

5 EMD567 F2A/B, F3A/B, F7A/B, F9A/B, BL1, BL2, FP7, FL9, FT, GP7, GP9 ,GP,GP28

E6, E7, E8, E9, NW2, NW3, NW4, SW1, SW7, SW8, SW9, SW600, SW900