XL SYSTEMS INC

Item #0001916

HO DC/DCC Diesel Sound Decoder Drop in for Atlas Genset Locomotives

• Triple core processor generating three independent diesel genset prime mover sounds

• 22 different types of horns and 8 types of bells

• Programmable individual sound volumes (16 levels)

• Programmable either 2-digit or 4-digit addresses

• Programmable start voltage and top voltage

• Programmable acceleration and decelaration rates

• Programmable 14, 28, 128 speed steps

• Back EMF load control

• Supports read back address and CV value

• Selectable factory default speed curve

• Advanced speed table control CV67-CV94

• Kick start voltage control CV65

• 17 light effects: ditch lights, mars light, gyra light, strobe light, prime strobe...

• 28 accessory functions (F1-F28)

• Compatible with NMRA DCC standards

• Complies with Part 15 of FCC Rules

• 16x35 mm speaker included

• Dimensions: 73.0mm x 17.6mm x 8.4mm

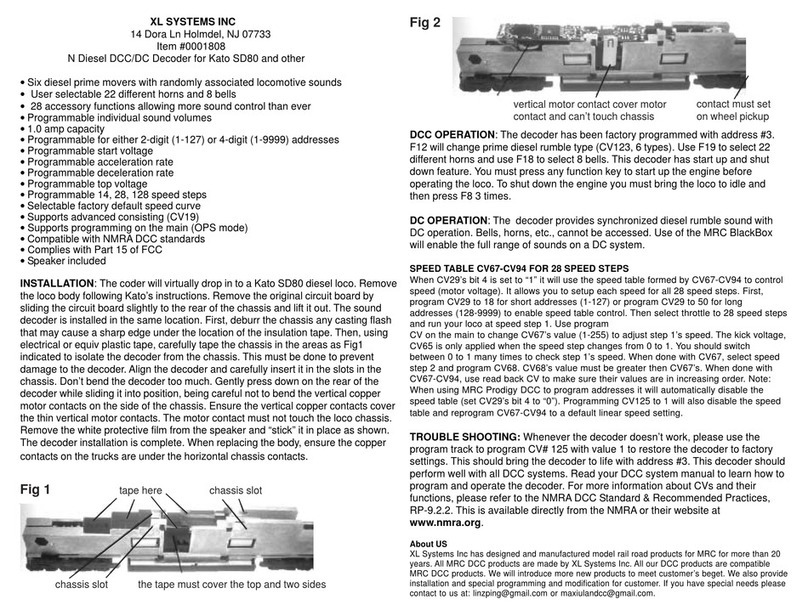

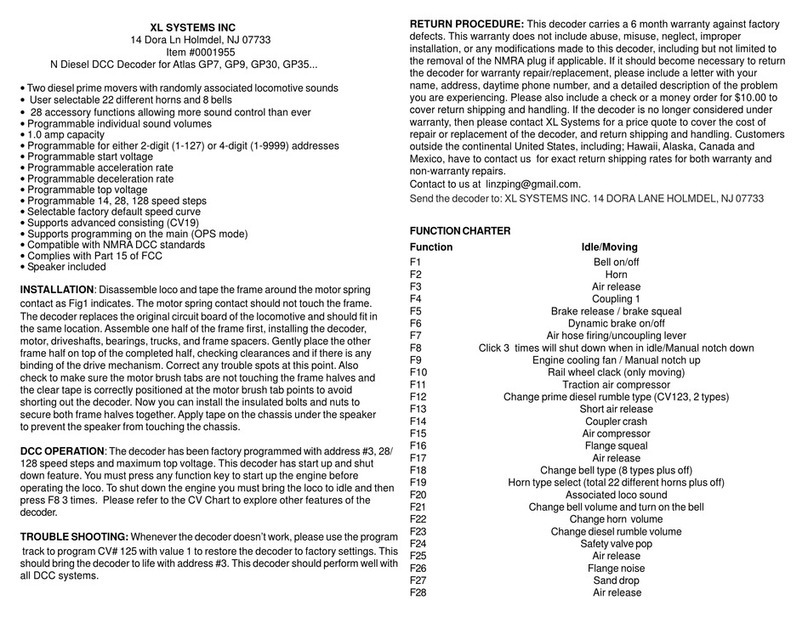

INSTALLATION: This decoder board completely replaces the PC Board in the Atlas

GenSet Loco. Slowly remove the body shell from the chassis of the loco. Don’t break

wires when you remove the body shell. We recomend using a dab of hot glue to secure the

headlight wires close to the headlight location inside the long hood of the body shell, to

avoid them breaking off. Use a 1" to 2" thin wire to connect (“T” connection) the two black

wires from the headlights.Tape the joint to avoid short circuit. This thin wire will be

connected to the tab marked “headlight com”. Remove the original board with two Atlas

ditch light boards. Remove the weight from the rear part of the chassis. Remove two

capacitorshidden under the weight. They will not be used. The speaker supplied with your

decoder fits snugly in place where you removed the two capacitors. We recomend using a

small bead of glue to fully secure the speaker to it’s location. Before installing the ditch

light boards please use clear tape to completely wrap both front and rear ditch light board

holders/slots to prevent the LEDs from touching the chassis, and shorting out. The ditch

light boards are already soldered to the decoder for your conveniance. Be very careful with

these wires as they are very fragile. The 4 ditch lights are tiny SMD led’s. Do not put force

on them during install or when removing the ditch light boards. You may need to remove

some of the tape from the board to ease the fit. However, you must make sure the rear

board be covered with tape, or insulated from the frame. Due to Atlas changing the chassis

after first run of production they have two versions of chassis. You may have problem of

fiting the light board . You can compare the light board to the original one. If our light

boards are shorter than yours, you have to cut the light board in the middle. Don’t not cut

the jump wire which links the two light together. Using clear tape wrap the pcb. Using the

supplied wiring diagram, attach the four pickup, two motor and three headlight wires to the

decoder board and secure using the plastic clips or by

soldering the wires to the tabs on the decoder. The black

motor wire may need to be extended. Use all the wire channels

in the chassis to route the wires going to the decoder and use

scotch tape in these locations to keep the wires from moving.

SERVICE BRAKING

To apply service brake set throttle to zero and press F5. The loco will slow down fast and you will

hear the brake squeal. You can pump the brake by turning F5 on and off to stop the loco at desired

location. The brake rate is proportional to deceleration rate that you program in CV4. If you forget to

turn off F5 and move the throttle up. The loco will move. However, when you release the throttle the

service brake will apply again. The service brake can only operate when throttle is at 0. If you don’t

hear the brake sound program CV115 with a value of 2.

OPERATION

The decoder has a default address #3. Select address #3 on your DCC system. Release service

brake (F5). You will hear the brake release sound when you turn off F5. Move up the throttle and the

loco should start to moveThe decoder has start up and shut down features. If the loco was previously

shut down you have to start up the engine. Press any function key to start up the engine before

operating the loco. To shut down the engine you must bring the loco to idle and then press F8 three

times. This decoder is default to manual notch setting (CV122=3). F9 will notch up and F8 will notch

down. If you want automatic notching enabled set CV 122 = 0. It has three independent diesel genset

prime mover sounds. The second engine will turn on at notch 4 and turn off below notch 4. The third

will turn on at notch 6 and and turn off below notch 6. This decoder also mimics the real GenSet, and

if left idling for a long period of time will shut down and restart automatically at specific intervals to

conserve fuel. Shutting off the sound in CV49 will not disable the horn. The decoder has two types of

diesel prime movers. You can use F12 or CV 123 to select the desired prime mover sound. You can

use F19 to select 34 different horn sounds and use F18 to select 8 different bell sounds. With MRC

Prodigy Advance2 DCC which has 28 functions, you can easily setup and access all the decoder’s

functions. If not, you may not be able to access all the features of the decoder. And you have to use

the CV program to setup the decoder.

Jump wire

Cut in the middle

light light

BACK EMF LOAD CONTROL (PID CONTROLLER)

This decoder is equipped with adjustable back EMF load control feature. It is a closed loop speed

control. With back EMF load control the locomotive will maintain its speed regardless of pulling up hill

or driving down hill. You may program the back EMF load control intensity, CV124, to a lower value to

get less back EMF load control. This will enable the locomotive to slow down during uphill travel like

real locomotive. The PID controller contains three components: proportional gain (CV113); the

integral gain (CV114); and derivative gain (fixed). Designing (tuning) a PID controller is a kind of

“rocket science”. So optimized these gains at the factory but still give the customer final adjustments.

We recommend that you do not change these settings. Too much gain may cause the motor to

oscilate (becomeunstable). Too little gain may cause slow response. Additional knowledge of PID

feedback control is required before attempting to adjust CV113 and CV114. If CV113 and CV114 are

programmed incorrectly, the locomotive will not run smothly. If this happens just program CV124 to 0.

HAED LIGHT EFFECT CV117

The decoder has 17 different lights

effects. CV 117 controls both front

and rear headlight effect.

0 Normal on/off 8 Marslight

1 Dyno effect (fading) 9 Single strobe light

2 Cim, bright, off cycle 10 Single strobe light

3 Rule 17 11 Double strobe light

4 Both healights on 12 Rotating beacon

5 Ditch light type A 13 Fred rear end flashing

6 Ditch light type B 14 Firebox flicker A

7 Gyra light 15 Firebox flicker B

pickup

left

pickup

right

motor

black

motor

red speaker

socket

headlight

com

front

light rear

light pickup

left

pickup

right