XL Systems Inc

14 Dora Ln Holmdel, NJ 07733

Diesel Sound Decoder with 6 Prime Mover Sound Item #0001909

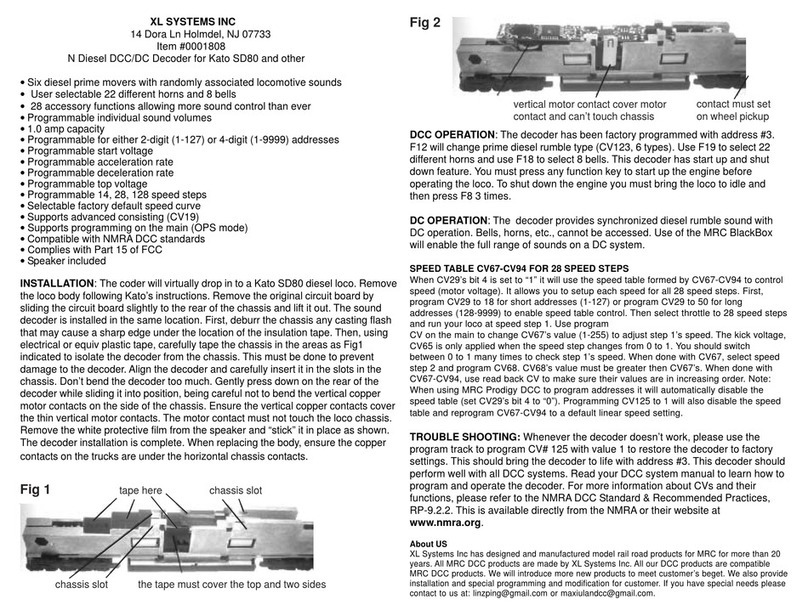

Thank you for purchasing our advanced DCC diesel 16 bit sound only

decoder. Combined with any non-sound power decoder installed in your

locomotive, and used with your favorite DCC System, our new sound only

decoder will make your model locomotive come to life.

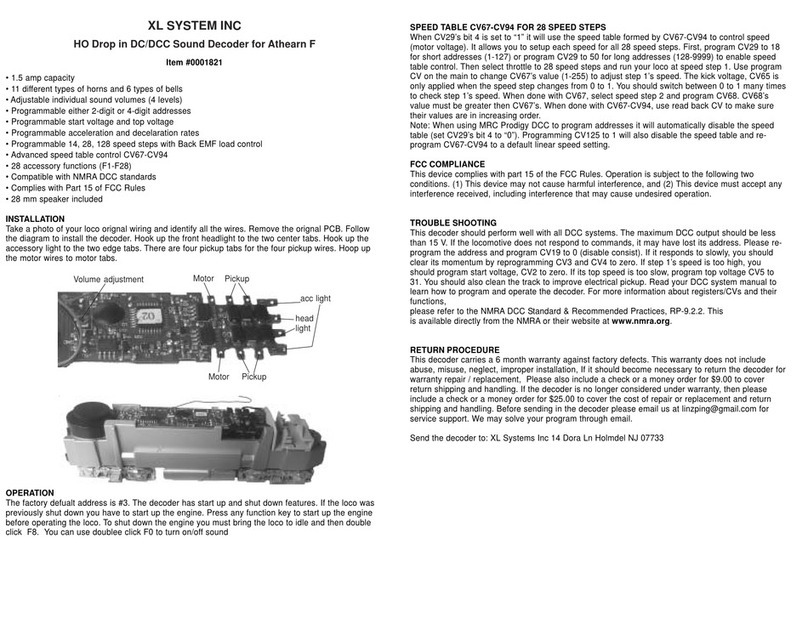

Easy installation - two wire only

Six synchronized diesel prime movers with random associated

locomotive sounds

28 functions (F1 - F28)

2 or 4-digit (1-9999) addressing

Programmable 14, 28, 128 speed steps

Programmable acceleration rate, deceleration rate

Programmable user selectable 22 different horns and 8 bells

Programmable individual sound volumes (16 levels)

Programmable master sound volumes (16 levels)

Supports advanced consisting (CV19)

Supports programming on the main (OPS mode)

Compatible with NMRA DCC standards

Complies with the part 15 of FCC

18mm speaker included

Dimensions: 17.4mm x 17.4mm x 4.0mm

Note- Instead of using CV3 and CV4, the decoder uses CV120 and CV121 as acceleration

and deceleration rates. So you can change its acceleration and deceleration rates without

changing CV3 or CV4 in your power decoder, if you already have these rates tailored for

your locomotives optimum performance.

ADDRESS PROGRAMMING:

The “Sounder” comes with a factory default address of #3, and 28 speed steps. If your

locomotive has a different address, and speed step already programmed into it, place the

locomotive, with decoder and Sounder installed, on your program track and reprogram it to

the address you had originally programmed it to. While it is on the program track, also

reprogram the locomotive to the speed step of your choice, (14-28/128). Since the decoder

does not have a motor driver, you can’t read back its CV.

ADDITIONAL INFORMATION:

The Sounder synchronized diesel sound only decoder should perform well when used with

other brand command systems, and decoders. See your DCC command stations manual

to learn how to program and operate any decoder. For more information about register/

CVs and their functions, please refer to the NMRA DCC Standard & Recommended

practices, RP-9.2.2 available directly from the NMRA or their website at www.nmra.org.

TROUBLE SHOOTING:

This decoder should perform well with all DCC systems. The maximum DCC output should

be less than 15 V. If the locomotive does not respond to commands, it may have lost its

address. Please reprogram the address and program CV19 to 0 (disable consist). If it

responds slowly, you should clear its momentum by reprogramming CV120 and CV121 to

zero. You should also clean the track to improve electrical pickup. Read your DCC system

manual to learn how to program and operate the decoder. Whenever the decoder doesn’t

work please use the program track to program CV# 125 with value 1 to restore the decoder

to factory settings. This should bring the decoder to life with address #3.

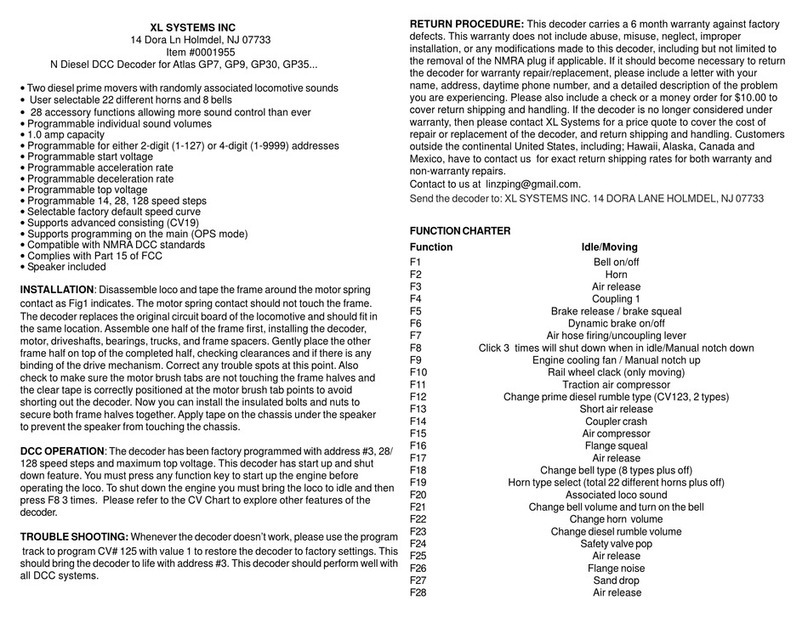

RETURN PROCEDURE:

This decoder carries a 6 month warranty against factory defects. This warranty does not

include abuse, misuse, neglect, improper installation, or any modifications made to this

decoder. If it should become necessary to return the decoder for warranty repair/

replacement, please include a copy of the original sales receipt. Please include a letter

(printed clearly) with your name, address, daytime phone number, and a detailed

description of the problem you are experiencing. Please also include a check or a money

order for $8.00 to cover return shipping and handling. If the decoder is no longer

considered under warranty, then please include a check or a money order for $12.00 to

cover the cost of repair or replacement and return shipping and handling.

Send the decoder to:

XL Systems Inc

14 Dora Ln

Holmdel, NJ 07733

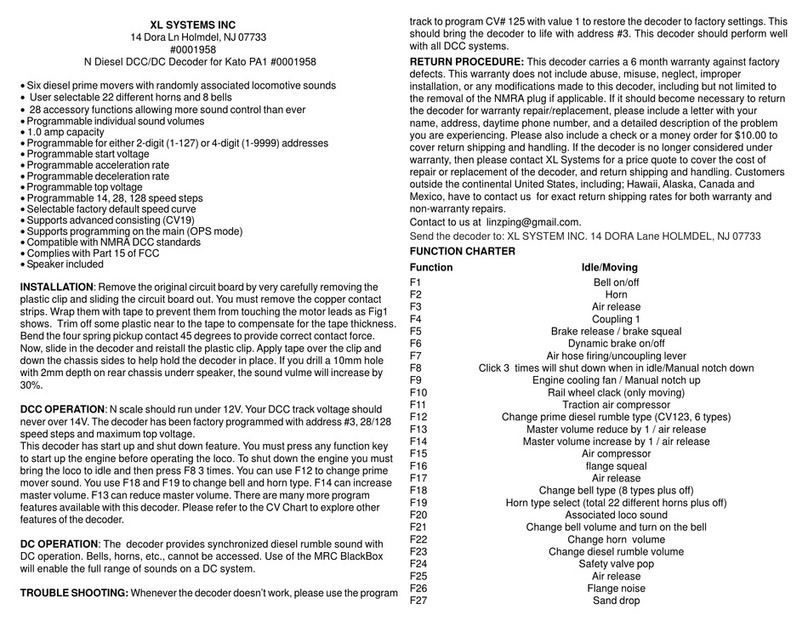

Function Idle/Moving

F1 Bell on/off

F2 Horn

F3 Air release

F4 Coupling 1

F5 Brake release / brake squeal

F6 Dynamic brake on/off

F7 Air hose firing/uncoupling lever

F8 Click 3 times will shut down when in idle/Manual notch down

F9 Engine cooling fan / Manual notch up

F10 Rail wheel clack (only moving)

F11 Traction air compressor

F12 Change prime diesel rumble type (CV123, 6 types)

F13 Master volume reduce by 1 / air release

F14 Master volume increase by 1 / air release

F15 Air compressor

F16 flange squeal

F17 Air release

F18 Change bell type (8 types plus off)

F19 Horn type select (total 22 different horns plus off)

F20 Associated loco sound

F21 Change bell volume and turn on the bell

F22 Change horn volume

F23 Change diesel rumble volume

F24 Safety valve pop

F25 Air release

F26 Flange noise

F27 Sand drop

F28 Air release

FUNCTION CHARTER: