7

Calibration

3.2 Conductivity

If installed, the conductivity/temperature sensor can measure and calculate conductivity, specific conductance (temperature

compensated conductivity), salinity, non-linear function (nLF) conductivity, TDS, resistivity, and density. Calibration is only

available for specific conductance, conductivity, and salinity. Calibrating one of these options automatically calibrates the other

conductivity/temperature parameters listed above. For both ease of use and accuracy, YSI recommends calibrating specific

conductance.

Select the appropriate calibration standard for the conductivity of the sampling environment. Standards at least 1 mS/ cm (1000

μs/cm) are recommended for the greatest stability. For fresh water applications, calibrate to 1,000. For salt water applications,

calibrate to 50,000 μS.

Conductivity Calibration

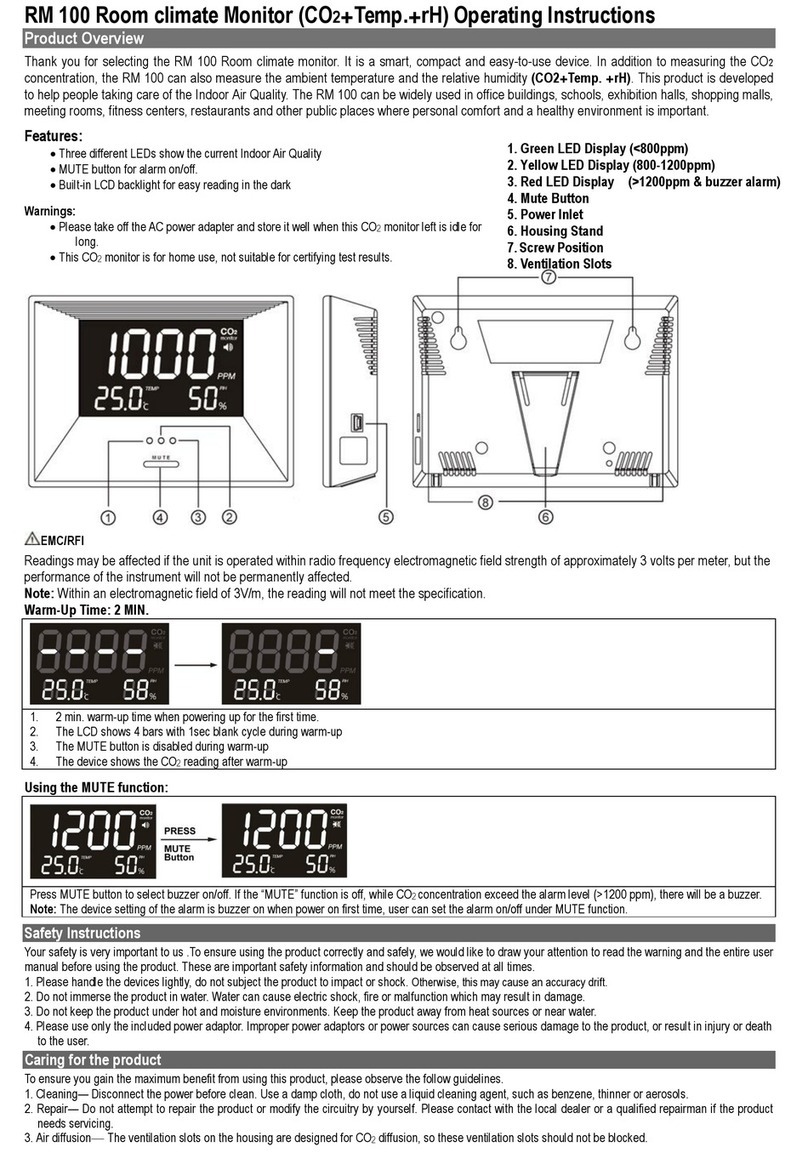

1. Make sure the conductivity sensor is clean prior to calibration. If necessary,

clean the conductivity cell with the supplied soft brush.

2. Place the correct amount of conductivity standard into a clean and dry or

pre-rinsed calibration cup.

3. Carefully immerse the sensors into the solution. Make sure the solution is

above the vent holes on the side of the conductivity sensor.

If using the ODO/CT assembly, ensure the vent holes at the top of the

sensor are completely immersed and the solution level is at least 1 cm

higher than the top vent holes (Figure 2). A graduated cylinder is included

with ODO/CT cable assemblies for the purpose of calibrating conductivity.

4. Gently rotate and/or move the sensor up and down to remove any

bubbles from the conductivity cell. Allow at least 40 seconds for

temperature equilibration before writing the value with the appropriate

Modbus command (see Modbus Configuration and Commands for

more details).

5. Rinse the sensor in clean water then dry.

NOTE: If the data is not stabilized after 40 seconds, gently rotate

the sensor or remove/reinstall the calibration cup to make

sure that no air bubbles are in the conductivity cell.

If you get calibration error messages, check for proper

sensor immersion, verify the calibration solutions is fresh,

the correct value has been entered into the handheld, and/

or try cleaning the sensor.

Figure 2 ODO/CT Cable Assembly

Top Vent

Holes

Side Vent

Holes