5

NOTE: Total discharge head should not exceed 4 feet (1.2m). To retain water in the bowl, the discharge

hose should be looped upward about 8 to 10” (20-25cm) above the base of the toilet and as near to the

toilet as can be practically accomplished without creating an unsightly plumbing situation.

CAUTION: Do not apply flame to the hose. Do not apply flame or heat to the plastic hose tails on the

toilet, rinse pump or solenoid valve. Do not use oils, greases or synthetic lubricants. Do not apply sealing

compounds to any hose connections. Do not over tighten hose clips.Any of these actions may result in

cracking or breakage of the plastic parts.

HAZARD RISK: Through-Hull Fittings – FOLLOW THESE INSTRUCTIONS!

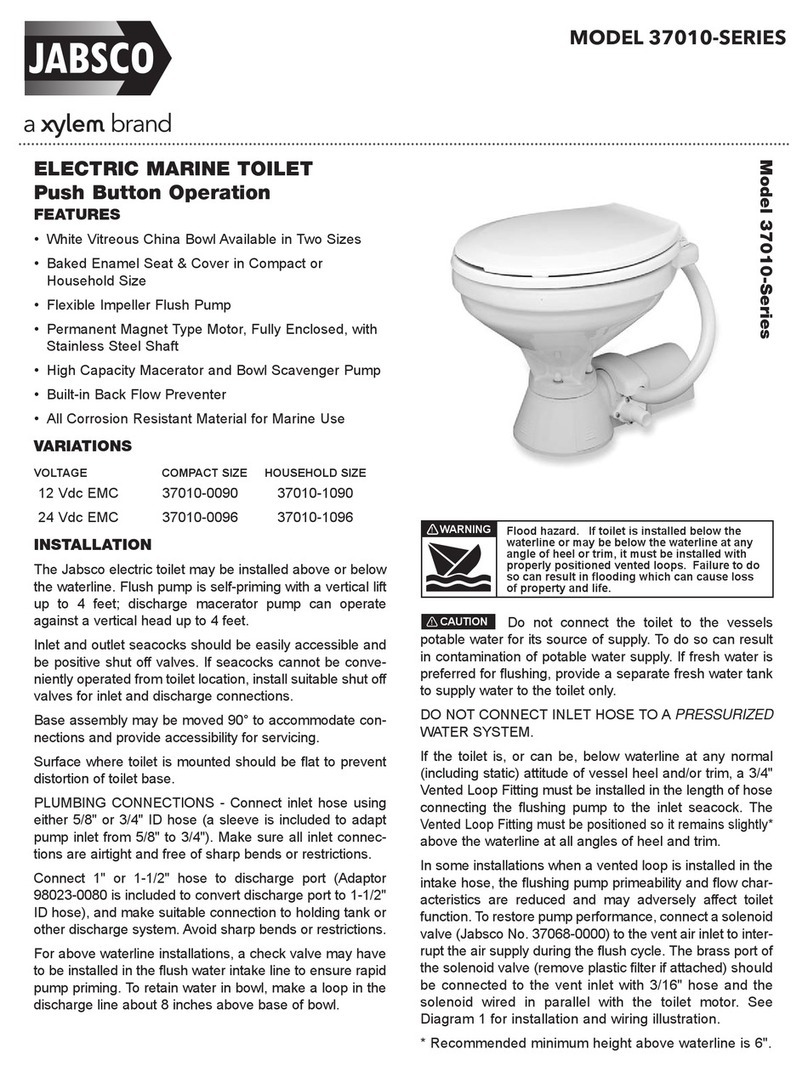

If the installation of the toilet results in it being connected to ANY through-hull fitting that may possibly be

below the waterline at ANY time, whether when the craft is at rest, underway and heeling or rolling or pitching,

you must install the toilet in accordance with these Installation Instructions. If you do not, water may flood in,

causing the craft to sink, which may result in loss of life.

HAZARD RISK: Accidental Damage – USE SEACOCKS!

If the toilet is connected to ANY through-hull fittings and if the toilet or pipework is damaged, water may flood

in causing the craft to sink, which may result in loss of life. Therefore, if you are making connections between

the toilet and ANY through-hull fittings that may possibly be below the waterline at ANYtime, full bore seacocks

must be fitted to those hull fittings,to allow them to be shut off.

The seacocks MUST also be positioned where they are easily accessible to all users of the toilet. If,for any reason,

it is not possible to do this, then secondary bore marine quality valves MUST be fitted to the hoses where they

are easily accessible.

HAZARD RISK: Bowl Rim Below Waterline – USE VENTED LOOPS!

If the toilet is connected to ANY through-hull fittings, and if the rim of the bowl falls below the waterline, water

may flood in causing the craft to sink, which may result in loss of life.

Therefore, if the rim of the toilet is less than 8” (20cm) above the waterline when the craft is at rest, or if there is

ANY possibility that the rim of the bowl may be below the waterline at ANY time, a ventilated anti-syphon loop

MUST be fitted in any pipework connected to a through-hull fitting,irrespective of whether inlet or outlet.

SPECIAL NOTE 1: The smaller bore inlet pipework is more hazardous than the larger outlet pipework.

Unless there is a ventilated anti-syphon loop in the inlet pipework, water will flow into the bowl whenever both

the inlet seacock is open and the rim of the bowl is below the actual waterline.

SPECIAL NOTE 2: Making a loop in the hose without fitting a vent may be just as hazardous as no loop at all,

because water may syphon over a loop. It is the vent that actually prevents the syphon.

Pipework – General Instructions for All Options

Hardware Requirements:

• Spiral reinforced smooth bore flexible hoses for both the 3/4” (19mm) inlet and the 1” (25mm) or 1.5” (38 mm) outlet

pipework. Toilet supplied with 1” (25 mm) to 1.5” (38 mm) adaptor

• Two stainless steel worm-drive hose clips for every hose tail connection.

• Secure the hose runs so that the hoses cannot move and chafe, and so that they do not exert any leverage on the hose

tail fittings to which they are connected, as this may cause adjacent joints to leak.

• Avoid sharp bends in the hoses as this may cause them to become kinked.

• Keep all pipework runs as straight and as short as possible, avoiding rising and falling over obstructions which creates

airlocks.

• If it is difficult to fit the hose onto the hose tails of the toilet or seacocks, lubricate it with water, or soften the hose by

dipping the end in hot water.

• Secure the ends of all hoses to the hose tails with two stainless steel worm-drive hose clips, ensuring that all inlet

connections are airtight and that all the outlet connections are water tight.