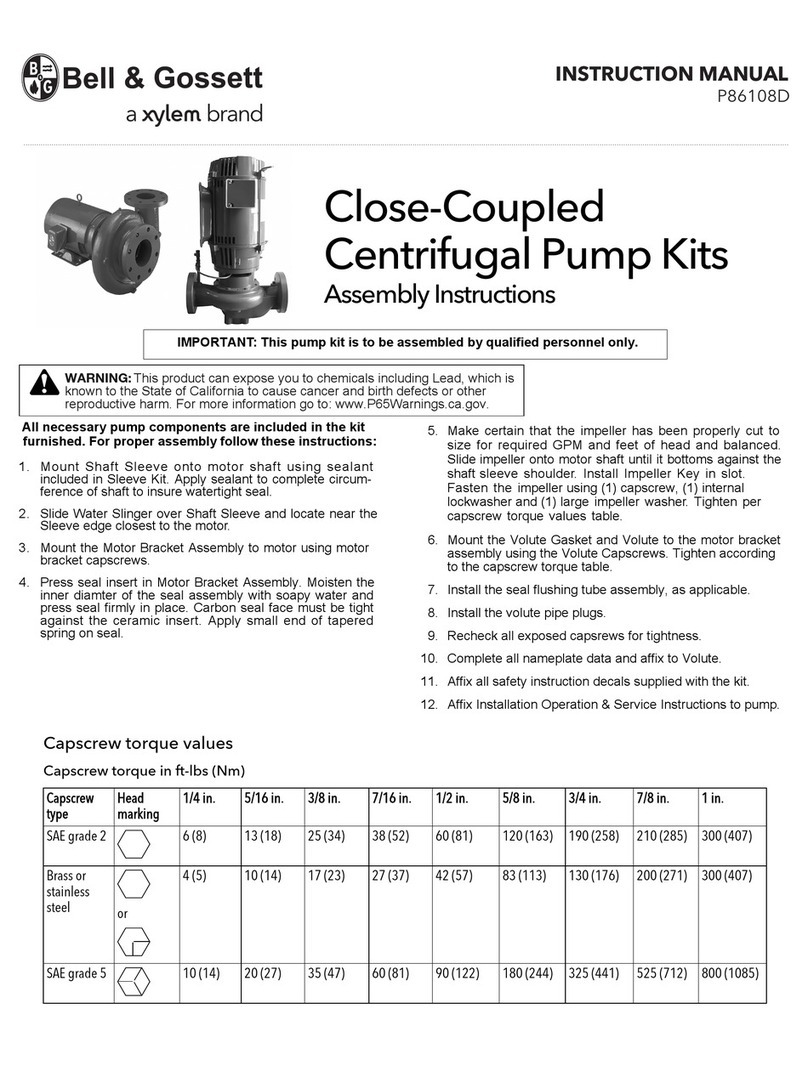

DIMENSIONAL DRAWING

Inches (Millimetres)

© Copyright 2009, ITT Corp All Rights Reserved Form: 43000-0737 Rev. 08/2009

For more information

visit us online at www.jabsco.com

12/07

AL¼ - 200 Self Priming Flexible Impeller Pump

Performance

Parts List

Dimensions in mm (inches)

AL¼ - 200 Series

Note : Performance shown is for a new pump, pumping water at

20ºC, performance may vary by up to 15%. Consult

factory for performance of alternative impeller compounds.

Key Description Part Number

A

Impeller Kit

(Contains Impeller (X),

O-Ring (X))

B

End Cover Kit

(Contains End Cover (X),

Screws (X), O-Ring (X))

C

Shaft Kit

(Contains Shaft (X),

Bearings (X), Retaining

Rings (X & X), Dust Shield

(X))

D

Service Kit

(Contains Impeller (X),

O-Ring (X), Mechanical

Seal (X), End Cover

Screws (X))

E

Seal Kit

(Contains Mechanical Seal

(X), O-Ring (X), Support

Washer (X))

Warranty: All products of the company are sold and all services of the company are offered subject to the company’s warranty and terms and conditions of sale, copies of which will be furnished upon request.

The information provided herein is for guidance only, it does not constitute a guarantee of the performance or specification of any individual product or component.

©Copyright 2003 ITT Industries 43000-0789

UK

Xylem

Bingley Road, Hoddesdon

Hertfordshire EN11 0BU

Tel: +44 (0)1992 450145

Fax: +44 (0)1992 467132

USA

Xylem

100 Cummings Center Drive

Suite 535-N, Beverly, MA 01915

Tel: +1 978 281-0440

Fax: +1 978 283-2619

ITALY

Xylem

Via Tommaseo, 6

20059 Vimercate, Milano

Tel: +39 039 685 2323

Fax: +39 039 666 307

GERMANY

Xylem

Oststrasse 28

22844 Norderstedt

Tel: +49-40-53 53 73-0

Fax: +49-40-53 53 73-11

JAPAN

Xylem

3-21-10, Shin-Yokohama

Kohoku-Ku, Yokohama, 222-0033

Tel: +81-045-475-8906

Fax: +81-045-477-1162

www.xyleminc.com

Warranty: All products of the company are sold, and all services of the company are offered subject to the company’s warranty and terms of sale, copies of which will

be furnished upon request. Details correct at time of printing. We reserve the right to change specifications without prior notice.

© Copyright 2015XylemInc. Jabsco is a trademark of Xylem Inc. or one of its subsidiaries. 43000-07

43000-0737 Rev. C 8/2015

COMMERCIAL WARRANTY

Warranty. For goods sold to commercial buyers, Seller warrants the goods sold to Buyer hereunder (with the exception of membranes, seals,

gaskets, elastomer materials, coatings and other "wear parts" or consumables all of which are not warranted except as otherwise provided in the

quotation or sales form) will be (i) be built in accordance with the specifications referred to in the quotation or sales form, if such specifications

are expressly made a part of this Agreement, and (ii) free from defects in material and workmanship for a period of one (1) year from the date of

installation or eighteen (18) months from the date of shipment (which date of shipment shall not be greater than thirty (30) days after receipt of

notice that the goods are ready to ship), whichever shall occur first, unless a longer period is specified in the product documentation (the ìWarran-

tyî).

Except as otherwise required by law, Seller shall, at its option and at no cost to Buyer, either repair or replace any product which fails to conform

with the Warranty provided Buyer gives written notice to Seller of any defects in material or workmanship within ten (10) days of the date when

any defects or non-conformance are first manifest. Under either repair or replacement option, Seller shall not be obligated to remove or pay for

the removal of the defective product or install or pay for the installation of the replaced or repaired product and Buyer shall be responsible for

all other costs, including, but not limited to, service costs, shipping fees and expenses. Seller shall have sole discretion as to the method or means

of repair or replacement. Buyerís failure to comply with Sellerís repair or replacement directions shall terminate Sellerís obligations under this

Warranty and render the Warranty void. Any parts repaired or replaced under the Warranty are warranted only for the balance of the warranty

period on the parts that were repaired or replaced. Seller shall have no warranty obligations to Buyer with respect to any product or parts of a

product that have been: (a) repaired by third parties other than Seller or without Sellerís written approval; (b) subject to misuse, misapplication,

neglect, alteration, accident, or physical damage; (c) used in a manner contrary to Sellerís instructions for installation, operation and mainte-

nance; (d) damaged from ordinary wear and tear, corrosion, or chemical attack; (e) damaged due to abnormal conditions, vibration, failure to

properly prime, or operation without flow; (f) damaged due to a defective power supply or improper electrical protection; or (g) damaged

resulting from the use of accessory equipment not sold or approved by Seller. In any case of products not manufactured by Seller, there is no

warranty from Seller; however, Seller will extend to Buyer any warranty received from Sellerís supplier of such products.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, GUARANTEES,

CONDITIONS OR TERMS OF WHATEVER NATURE RELATING TO THE GOODS PROVIDED HEREUNDER, INCLUDING WITHOUT LIMITA-

TION ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE HEREBY EXPRESSLY

DISCLAIMED AND EXCLUDED. EXCEPT AS OTHERWISE REQUIRED BY LAW, BUYERíS EXCLUSIVE REMEDY AND SELLERíS AGGREGATE

LIABILITY FOR BREACH OF ANY OF THE FOREGOING WARRANTIES ARE LIMITED TO REPAIRING OR REPLACING THE PRODUCT AND

SHALL IN ALL CASES BE LIMITED TO THE AMOUNT PAID BY THE BUYER FOR THE DEFECTIVE PRODUCT. IN NO EVENT SHALL SELLER BE

LIABLE FOR ANY OTHER FORM OF DAMAGES, WHETHER DIRECT, INDIRECT, LIQUIDATED, INCIDENTAL, CONSEQUENTIAL, PUNITIVE,

EXEMPLARY OR SPECIAL DAMAGES, INCLUDING BUT NOT LIMITED TO LOSS OF PROFIT, LOSS OF ANTICIPATED SAVINGS OR REVENUE,

LOSS OF INCOME, LOSS OF BUSINESS, LOSS OF PRODUCTION, LOSS OF OPPORTUNITY OR LOSS OF REPUTATION.