ELECTRIC BILGE

PUMPS

36600 Series

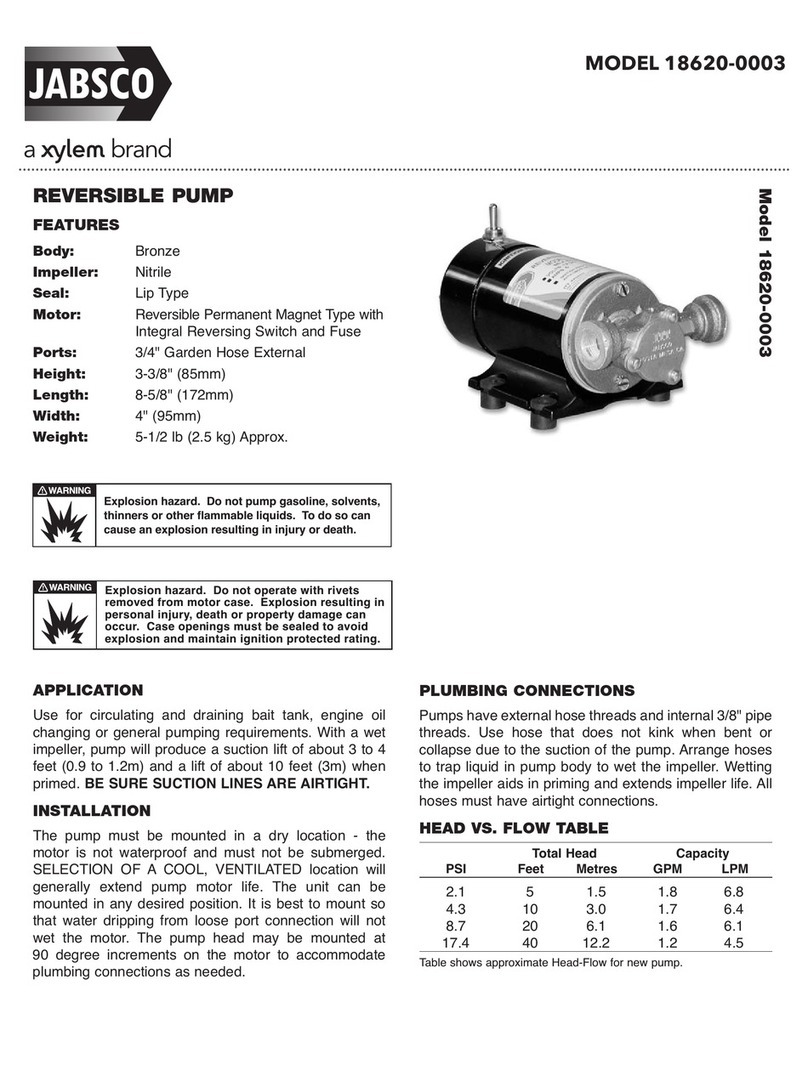

FEATURES

• Self-Priming

• Diaphragm Design Allows Dry

Running

• Quiet Operation

• Built-In Hydraulic Pulsation Dampener

• Permanently Lubricated Ball Bearings

on Shaft and Connecting Rod

• Large Vibration Absorbing Pads

• Corrosion Resistant Materials

Throughout for Sea Water Service

• Meets USCG Regulation 183.410

and ISO 8846 MARINE for Ignition

Protection

SPECIFICATIONS

Open Flow: 8.0 GPM

Vert. Dry

Suction Lift: 10 feet (3 m)

Ports: 3/4” Slip-on Hose

Weight: 11 lb

APPLICATION

Jabsco diaphragm bilge pumps are self-priming, so they can be mounted

above and outside of harsh bilge environments. Because they are mounted

remotely, the intake hose can be routed to the lowest point of the bilge

regardless of space limitations. They are supplied with an in-line strainer

to prevent damaging debris from entering pump. The reliable diaphragm

design is not damaged by dry running.

MAINTENANCE

Winter Storage

When possible, it is preferred that the complete pump or at least motor,

diaphragm and valves be removed and stored in a warm dry place. If this

is not possible, the pump must be completely drained, hoses removed and

pump run until all water is expelled.

CAUTION DO NOT USE AUTOMOTIVE TYPE ANTI-FREEZE.

Mounting

Mount upright in a dry location (above highest bilge water level) on a solid

surface. Adjust belt tension for 1/4” play between pulleys.

Plumbing

For intake and discharge use 3/4” ID non-collapsible hose. Keep intake

and discharge lines free of kinks and restrictions. Use the 3/4” bilge in-line

stainer (Model 36200-0000) in the intake line from the bilge to protect

pump from debris. Use a 3/4” thru-hull fitting for discharge.

WIRING FOR DC VOLTAGE MODELS - See Figure 1 & 3.

Wire pump in a circuit independent of all other electrical fixtures. Use

stranded copper wire. Install fuse/breaker in positive circuit. See table for

recommended wire and fuse size. See diagram for wiring connections.

After installation, it is recommended that voltage be checked at the motor

terminals with motor operating under full load and all other appliances in

the circuit operating. Voltage should not be less than 90% of rated motor

voltage.

WIRING FOR AC VOLTAGE MODELS

Use 16 gauge standard copper wire for lengths up to 100 feet from power

source. Connect the grounded, unswitched conductor (white) to the white

motor lead. Connect the ungrounded switched conductor (black ) to the

black motor lead. This conductor should include, at the power source, a

1.5 amp 125 Volt fuse. The green motor lead must be connected to the AC

circuit ground.

ES

Dimensional Drawings

Standard Models

Model No. Voltage Amperage Nominal

36600-0000 12 Vdc 11.0

36600-0010 24 Vdc 5.5

36600-0031 115 Vac 1.0

MINIMUM WIRE SIZES

Model

Number Voltage

Wire Size for

Length of Run

1–25’ 25–50’

Fuse/

Breaker*

36600-0000 12 Vdc 12 AWG 10 AWG 15 amp

36600-0010 24 Vdc 14 AWG 14 AWG 8 amp

36600-0031 115 Vdc 16 AWG 16 AWG 1-1/2 amp

*Customer supplied, not included with pump.

Rule Model 41/42

1

WARNING

Wiring must comply with applicable electrical standards and

include a properly sized fuse or circuit breaker. IMPROPER WIRING

CAN CAUSE A FIRE RESULTING IN INJURY OR DEATH.

FIRE HAZARD

3

SERVICIO - Ver la gura 2.

1. Desconecte la corriente eléctrica de la bomba. Retire los cuatro pernos de fijación.

2. Levante el contraeje y el conjunto del diafragma de la base de la bomba.

3. Retire los dos tornillos de retención del diafragma y el retenedor del diafragma.

4. Retire la tuerca de fijación. Retire el vástago de conexión y el diafragma del contraeje, luego

desatornille el perno para separar el diafragma y las placas.

5. Inspeccione el diafragma para asegurar que no tenga cortes o grietas. Inspeccione el cojinete

del ensamblaje del vástago para asegurar que no muestre un desgaste excesivo. Reemplácelo

si muestra mucho desgaste.

6. Sin apretar, vuelva a ensamblar el diafragma, las placas del diafragma, la arandela y el perno

del diafragma con el vástago de conexión. Fije firmemente el vástago de conexión al contraeje

con una tuerca de fijación. Fije el diafragma a la montura del motor con el retenedor del

diafragma y los dos tornillos.

7. Apriete el perno del vástago de conexión.

REEMPLAZO DE VÁLVULAS - Ver la Figura 2.

1. Desconecte la corriente eléctrica de la bomba. Retire los cuatro pernos de fijación.

2. Levante el contraeje y el diafragma adjunto de la base de la bomba para que las válvulas

queden expuestas. Retire y limpie o reemplace las válvulas.

3. Instale las válvulas, asegurando que la aleta de hule esté hacia ARRIBA en la toma y hacia

ABAJO en la descarga.

4. Vuelva a colocar el ensamblaje del motor, el soporte y el diafragma y fíjelo de forma uniforme

a la base con los cuatro pernos de fijación.

REEMPLAZO DE LOS HUMIDIFICADORES DE PULSACIÓN - Ver la Figura 2.

1. Desconecte los cables de alimentación de la bomba y retírela del soporte.

2. Retire los nueve tornillos inferiores de la tapa y los tres tornillos inferiores de la placa. Retire la

tapa inferior y la placa. Saque y reemplace los humidificadores de pulsación.

3. Vuelva a colocar la tapa inferior, la placa y los tornillos. Apriete los tornillos de forma

uniforme para asegurar que quede sellada contra aire y agua.

4. Vuelva a instalar la bomba y conecte los cables de corriente.

RESOLUCIÓN DE PROBLEMAS

PROBLEMA SOLUCIÓN

Pérdida de succión para bombear -Escape de aire en la línea de succión.

-La toma de la sentina no está sumergida.

-Manguera de entrada torcida u obstruida.

-Válvula de toma o descarga atorada o sucia.

-Diafragma perforado.

Funcionamiento irregular o con ruido. -Manguera de entrada o descarga torcida u obstruida.

-La bomba no está montada firmemente.

-Tornillo excéntrico flojo.

-Humidificador de pulsación perforado o colapsado.

PRECAUCIÓN

POSIBLE INCOMPATIBILIDAD DE COMPONENTES – SÓLO PARA AGUA

PRECAUCIÓN

LA BASE DEL MOTOR SE PODRÍA CALENTAR AL OPERAR DURANTE PERÍODOS

LARGOS. EL CONTACTO PROLONGADO CON LA PIEL PUEDE CAUSAR QUEMADURAS.