A. LIMITED WARRANTY:

absco warrants that at the time of shipment, the

products manufactured by absco and sold hereunder

shall be in conformity with applicable written

specifications and descriptions referred to or set

forth herein, free from defects in material and,

merchantable, and suitable for a particular purpose,

provided such is implied by State law under the

circumstances of this sale.

B. WARRANTY ADJUSTMENT:

1. absco agrees to repair or furnish a replacement for,

but not to remove or install, any product or

component thereof which, within one (1) year from

date of purchase, shall upon test and examination

by absco prove defective within the above

warranty. Receipt verifying purchase date is required

to obtain adjustment.

2. Buyer shall notify absco of any defect within this

warranty no later than ninety (90) days after the

defect is discovered.

C. EXCLUSIONS FROM WARRANTY AND

LIMITATION OF LIABILITY:

1. The foregoing warranty is limited solely as set

forth herein and applies only for the period

designated above.

2. ABSCO SHALL NOT BE LIABLE FOR ANY LOSS,

DAMAGE, SPECIAL OR CONSEQUENTIAL

DAMAGE OF ANY KIND, WHETHER BASED

UPON WARRANTY, CONTRACT, NEGLIGENCE,

OR STRICT LIABILITY ARISING IN CONNECTION

WITH THE SALE, USE, OR REPAIR OF THE

PRODUCT.

3. THE MAXIMUM LIABILITY OF ABSCO IN

CONNECTION WITH THIS WARRANTY SHALL

NOT IN ANY CASE EXCEED THE CONTRACT

PRICE FOR THE PRODUCT CLAIMED TO BE

DEFECTIVE OR UNSUITABLE.

4. This warranty does not extend to any product

manufactured by absco which has been subjected

to misuse, neglect, accident, improper installation, or

use in violation of instructions furnished by absco.

5. This warranty does not extend to or apply to any unit

which has been repaired or altered at any place

other than absco’s factory, or by persons not

expressly approved by absco, nor to any unit the

serial number, model number, or identification of

which has been removed, defaced or changed.

6. Components manufactured by any supplier other

than absco shall bear only that warranty made by

the manufacturer of that product.

7. This warranty applies to products defined as

“consumer products” by the Consumer Product

Warranties Act as from time to time amended.

D. CONSUMER RIGHTS:

This warranty gives you specific legal rights, and you

may have other rights which vary from state to state.

Some states do not allow exclusion or limitation

of damages.

STANDARD WARRANTY: If the products manufactured

and sold hereunder are not Consumer Products, the

warranty extended to Buyer shall be as set forth in

subparagraphs (A), (B), and (C), EXCEPT THAT ALL

EXPRESS OR IMPLIED WARRANTIES OR

MERCHANTABILITY OR SUITABILITY FOR ANY

PARTICULAR PURPOSE ARE EXCLUDED.

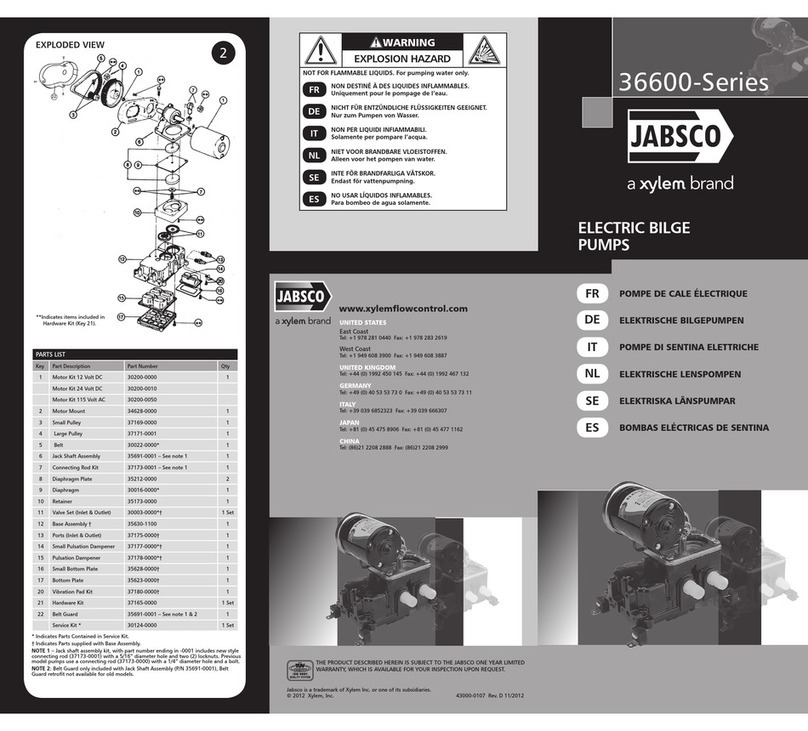

ONE YEAR LIMITED WARRANTY

THE PRODUCTS DESCRIBED HEREIN ARE

SUB ECT TO THE ABSCO ONE YEAR LIMITED

WARRANTY, WHICH IS AVAILABLE FOR YOUR

INSPECTION UPON REQUEST.

Jabsco is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem, Inc. 43000-0462 Re B 10/2012

www.xylemflowcontrol.com

Jabsco, 100 Cummings Center, Ste. 535-N, Beverly, MA 01915

Tel: +1 978 281 0440 Fax: +1 978 283 2619

Jabsco, Bingley Road, Hoddesdon, Hertfordshire, EN11 0BU

Tel: +44 (0) 1992 450 145 Fax: +44 (0) 1992 467 132

NHK Jabsco Co Ltd, 3-21-10, Shin - Yokohama Kohoku-ku, Yokohama 222

Tel: +81 (0) 45 475 8906 Fax: +81 (0) 45 475 8908

Jabsco GmbH, Oststraße 28, 22844 Norderstedt

Tel: +49 (0) 40 53 53 73 0 Fax: +49 (0) 49 53 53 73 11

Jabsco Italia, s.r.l., Via Tommaseo, 6, 20059 Vimercate, Milano

Tel: +39 039 685 2323 Fax: +39 039 666 307

USA

UK

JAPAN

GERMANY

ITALY