Xylem Lowara Scuba User manual

Other Xylem Water Pump manuals

Xylem

Xylem Rule Mate RM500A User manual

Xylem

Xylem Goulds 3642 User manual

Xylem

Xylem Lowara Sekamatik 100 Series User manual

Xylem

Xylem GOULDS ICS User manual

Xylem

Xylem Lowara Sekamatik 200 Series General instructions

Xylem

Xylem GOULDS 45HB Operating instructions

Xylem

Xylem Goulds LB Series User manual

Xylem

Xylem Lowara e-SV 1 Series User manual

Xylem

Xylem GOULDS 2GFK2412H User manual

Xylem

Xylem JABSCO 23920 Series User manual

Xylem

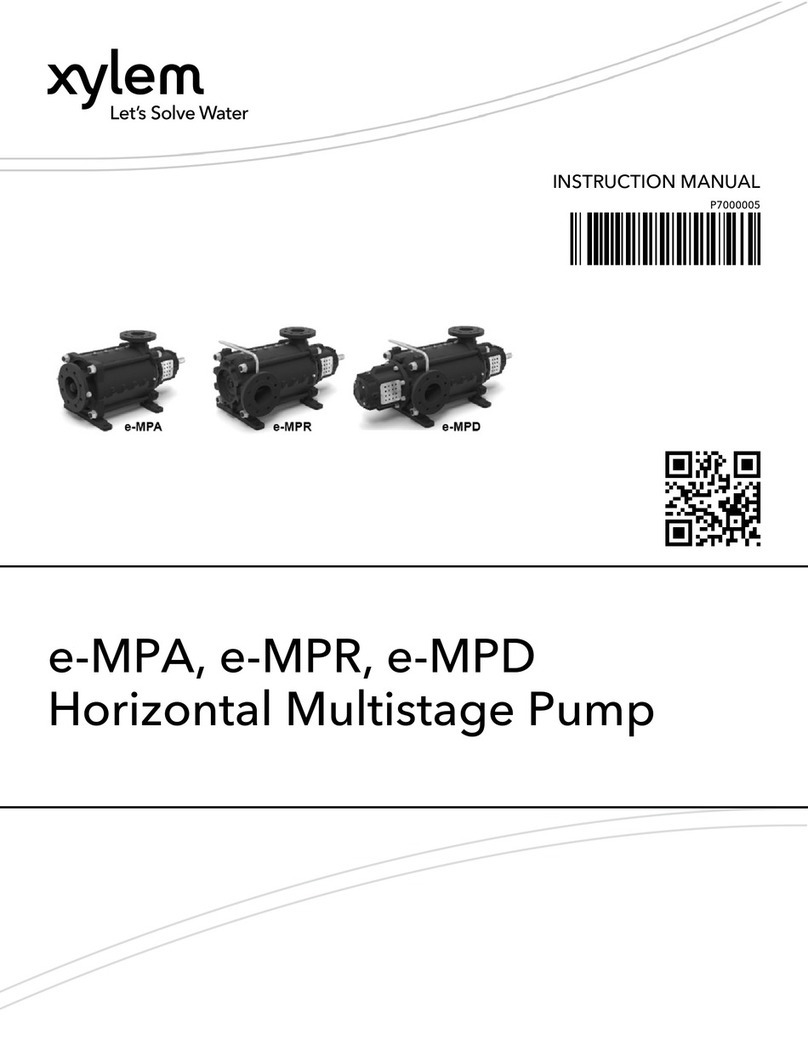

Xylem e-IXP Manual

Xylem

Xylem Goulds SHV Series Manual

Xylem

Xylem Flygt 3102 Series User manual

Xylem

Xylem Lowara Scuba Series Original instructions

Xylem

Xylem FLOJET BW5000 Series User manual

Xylem

Xylem LOWARA ecocirc PRO User manual

Xylem

Xylem Bell & Gossett TECHNOForce e-HV Series User manual

Xylem

Xylem Goulds Marlow Series User manual

Xylem

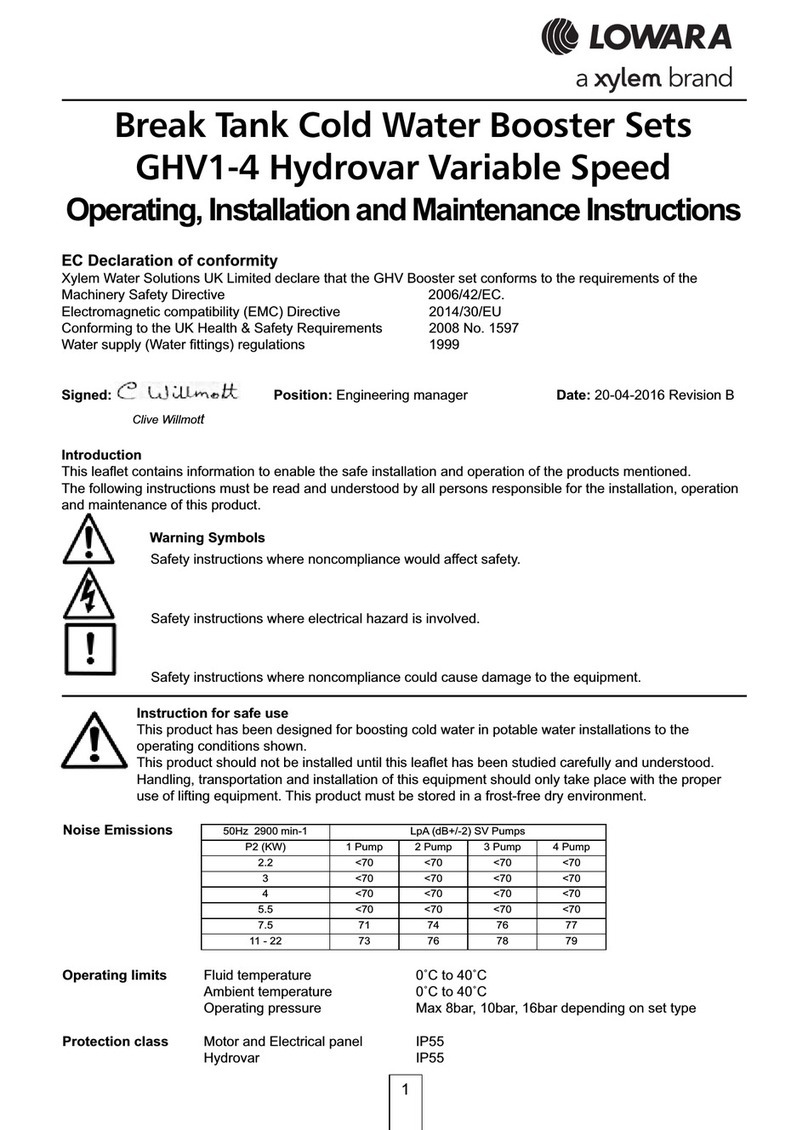

Xylem Lowara GHV1 User manual

Xylem

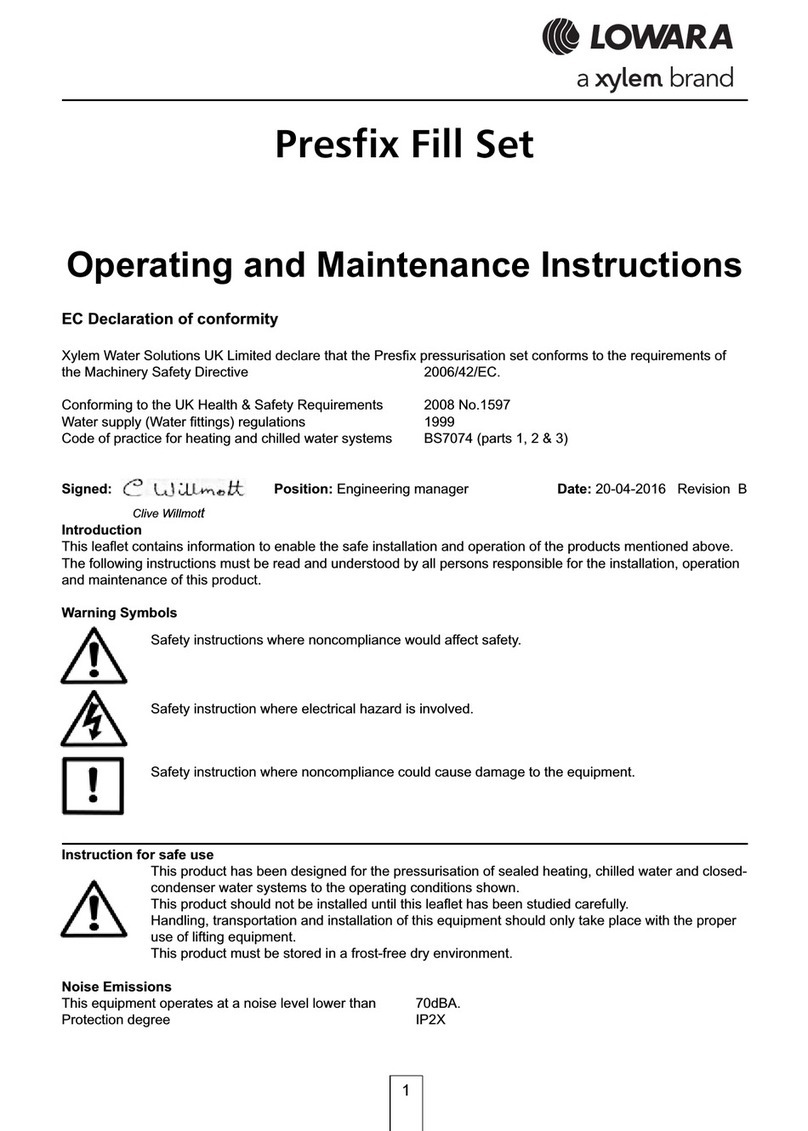

Xylem LOWARA Manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual

GÜDE

GÜDE HWW 900 GC Translation of the original instructions