順送りカット機能

順送りカット機能

SELECT

9

START

START

Green LED

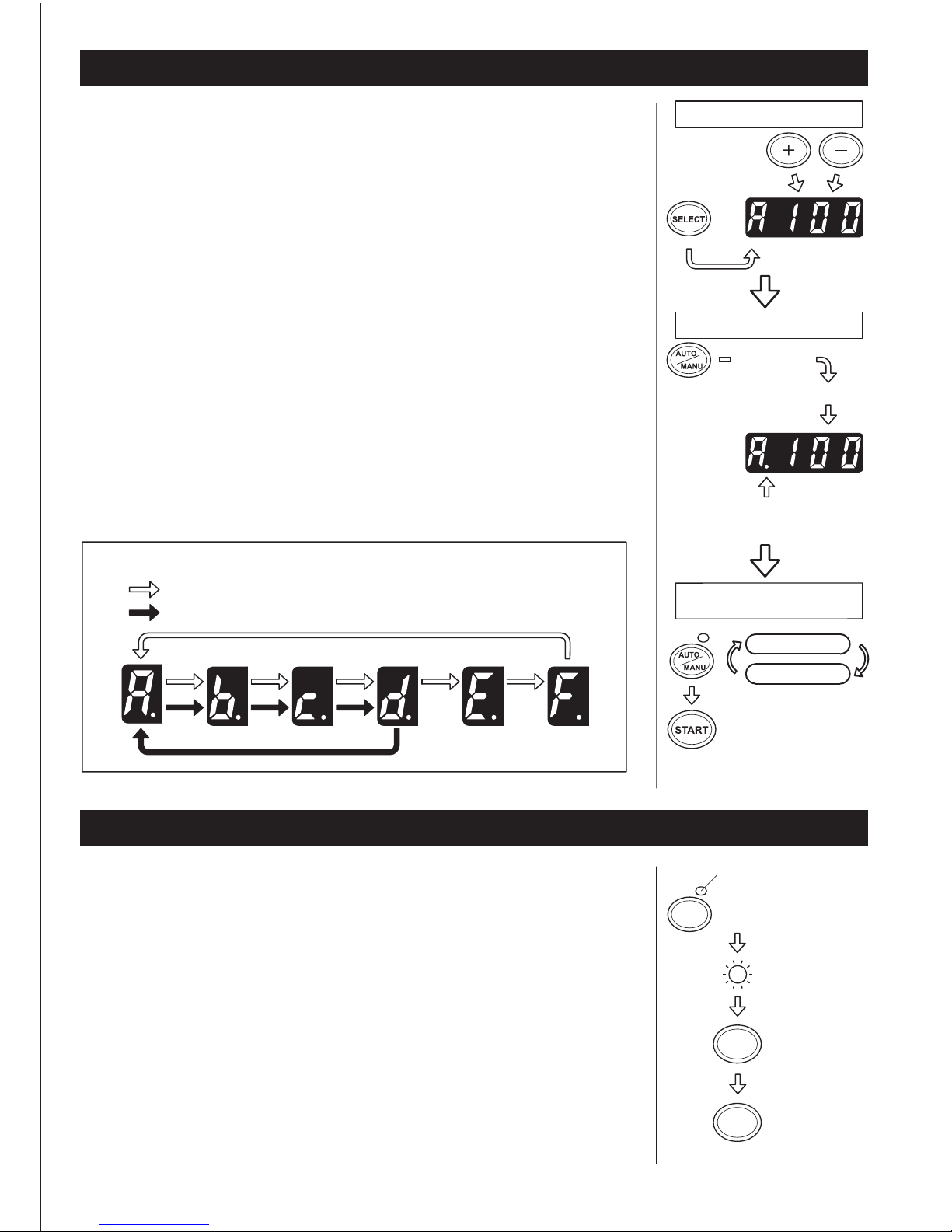

Programing Function

Folding Mode

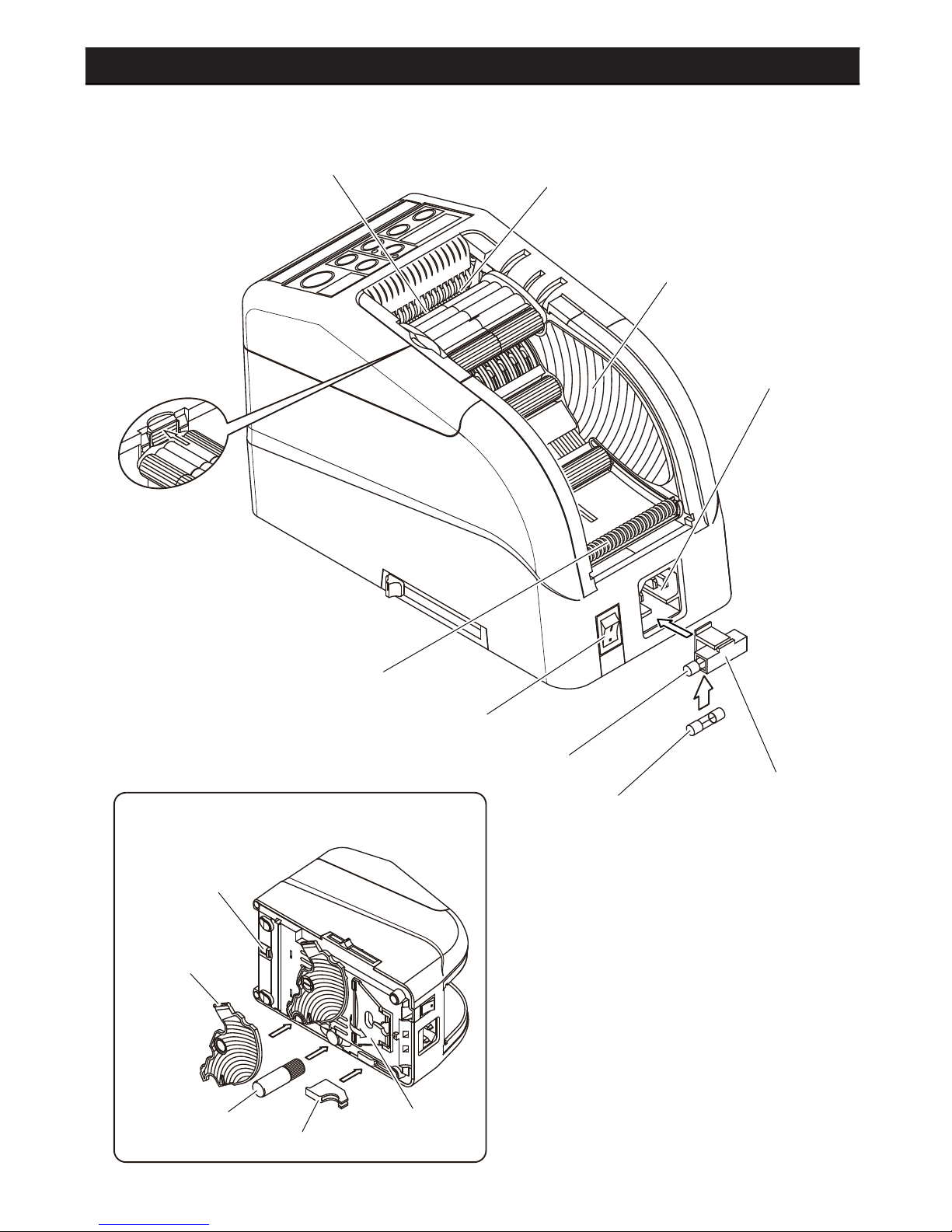

Function that cuts the material registered from A to F accordingly.

As refer to the following figure, operation will keep working.

This function may apply every mode.

◆Please follow the instruction on page 7.

◆Set the cutting length from A to F as you prefer.

◆Please set the cutting length in ZERO for between B to F if not necessary.

Then skip the position registered with ZERO accordingly and operate

repeatedly.

◆Apply the cutting length to your first cutting.

◆Press AUTO/MANUAL BUTTON more than 1 second.

Then [ . ] will appear on the lower right of Alphabet.

◆Press AUTO/MANUAL button and select AUTO MODE or MANUAL MODE.

◆Press START BUTTON and tape is ready to take.

When setting MANUAL MODE, the next cutting length will be desplayed.

When setting AUTO MODE, the next cutting tape is ready to take with

displaying the cutting length.

◆When discontinuing Program Function, please press AUTO/MANUAL

BUTTON longer and make sure that [ . ] is eliminated.

Operating Example

in the case of 6 different cut length setting

in the case of zero setting for E. F.

A~u:A 100mm

Set a cutting length

Programing Function setting

Press more

than 1 second

Press more

than 1 second

Buzzer sound

Buzzer sound

Setting

example

AUTO/MANUAL setting

MANUAL MODE

AUTO MODE

Confirm [ . ] description

Display the first cutting length

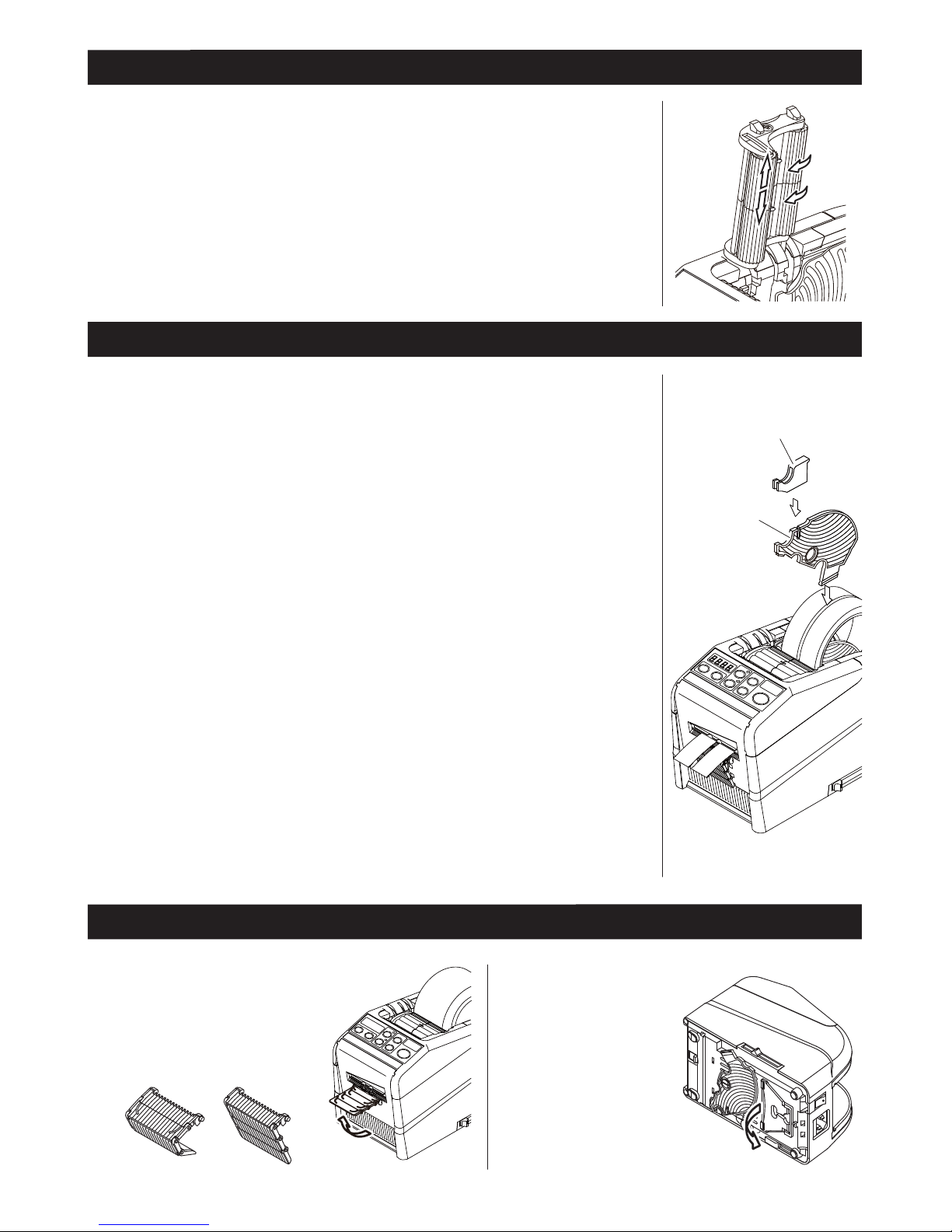

This mode is to fold the tape edge.

This mode can be used with other function.

◆Press SELECT BUTTON more than 1 second.

Green LED will be flashing if pressing SELECT BUTTON more than 1

second. If setting is completed and press START BUTTON, a piece of

tape with folding the edge as set the cutting length will be ready to take

after pressing START BUTTON again.

◆Set other mode as depends on your requirement.

◆In the case of folding mode, minimum cutting length is 15mm.

The folding length is fixed by 7mm.

◆When cancelling folding mode, please press SELECT BUTTON more

than 1 second. Please make sure that green LED is off.

Green LED Flassing

Feed a tape without

folding the edge

Feed a tape with

folding the edge