-------------------------------------Introduction

,-,.

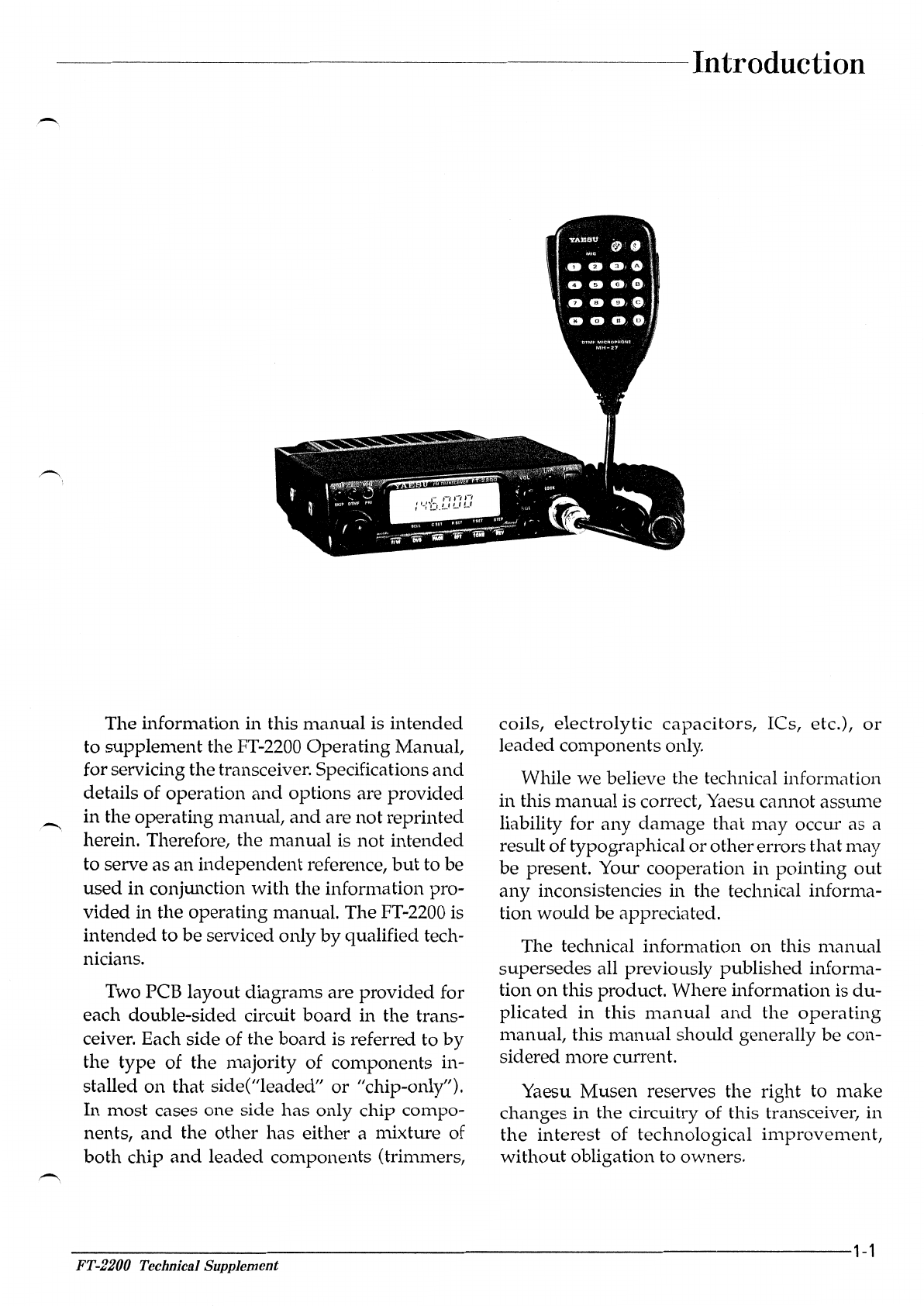

The information in this manual is intended

to supplement the

FT-2200

Operating Manual,

for servicing the transceiver. Specifications

and

details of operation

and

options are provided

in the operating manual,

and

are not reprinted

herein. Therefore, the manual is not intended

to serve as

an

independent reference,

but

to be

used in conjunction with the information pro-

vided

in the operating manual. The

FT-2200

is

intended to

be

serviced only

by

qualified tech-

nicians.

Two PCB layout diagrams are provided for

each double-sided circuit

board

in the trans-

ceiver. Each side of the board is referred to

by

the type of the majority of components in-

stalled on that side("leaded"

or

"chip-only").

In most cases one side has only chip compo-

nents,

and

the other has either a mixture of

both

chip

and

leaded components (trimmers,

coils, electrolytic

capacitors,

ICs, etc.),

or

leaded components only.

While

we

believe the technical information

in this manual is correct, Yaesu cannot assume

liability for

any

damage that

may

occur as a

result oftypographical

or

othererrorsthatmay

be present. Your cooperation

in

pointing

out

any

inconsistencies in the technical informa-

tion would be appreciated.

The technical information on this manual

supersedes all previously published informa-

tion

on

this product. Where information is

du-

plicated

in

this

manual

and

the

operating

manual, this manual should generally be con-

sidered more current.

Yaesu Musen reserves the right to make

changes

in

the circuitry of this transceiver, in

the

interest of technological

improvement,

without obligation to owners.

-----------------------------1-1

FT-2200 Technical Supplement