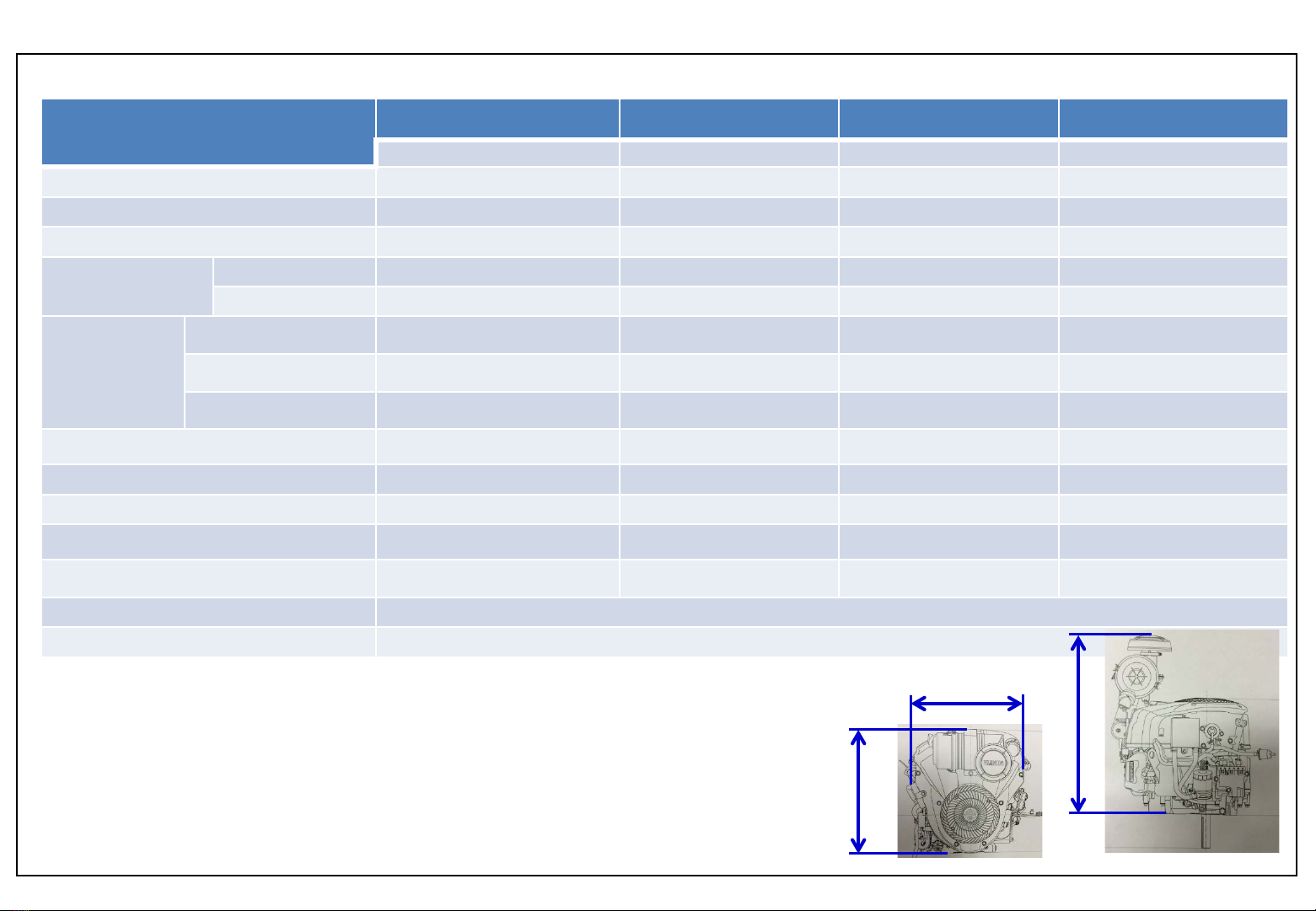

Specification

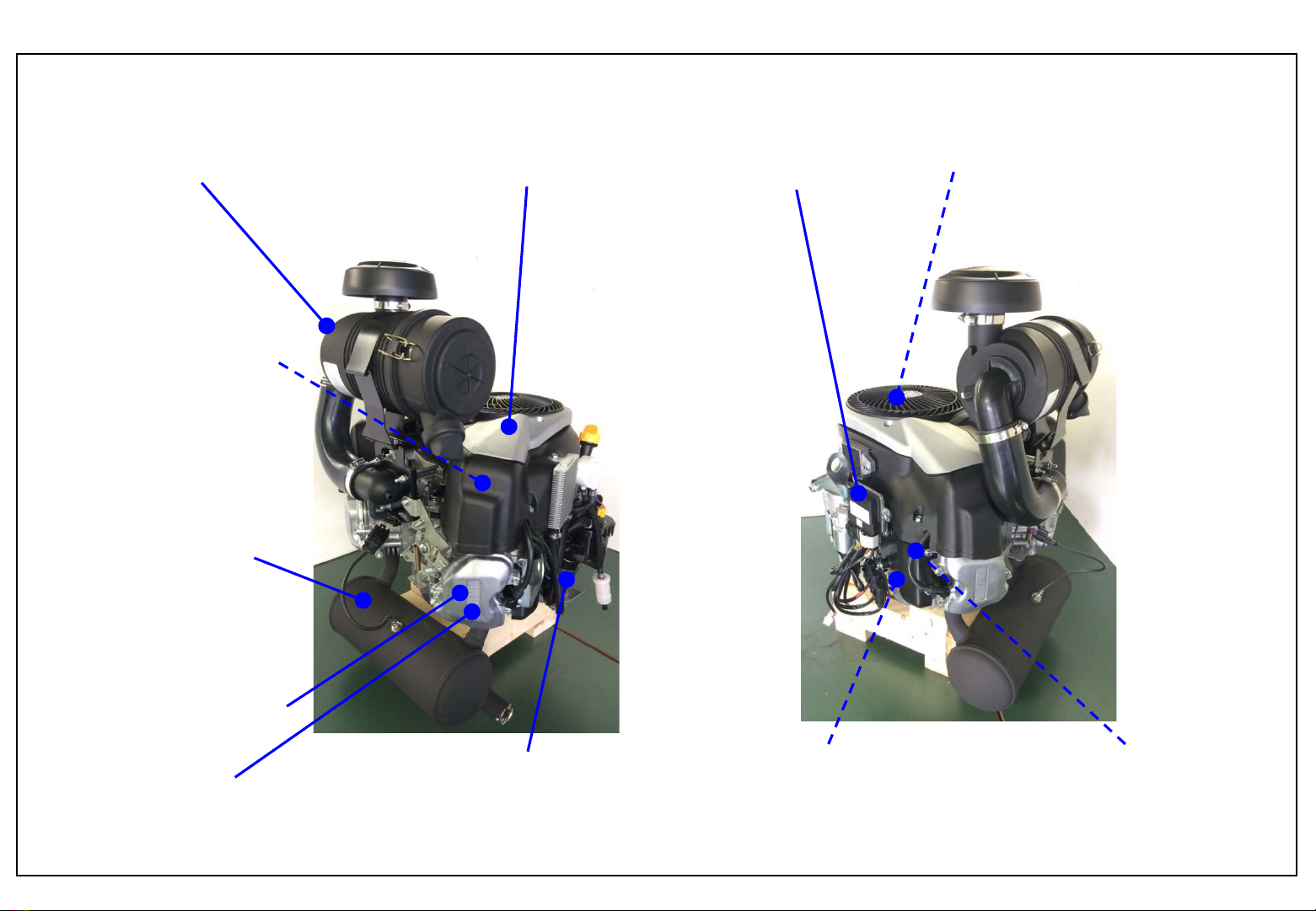

Model :MX825V-EFI

Model Name MX825V-EFI ECV 880 Vanguard 810 FX850V

Yamaha Kohler B&S Kawasaki

Dimensions* (in.) L x W x H 19.6 x 18.3 x 25.2 19.7 x 20.5 x 24 19.9 x 18.5 x 22.9 18.9 x 18.1 x 24.2

Weight –kg (lbs)60.0 (132.2) 61.7 (136) 41.3 (91) 47.6 (105)

Displacement –cc (ci) 824 (50.3) 824 (50.3) 810 (49.4) 852 (51.9)

Maximum Power

SAE J1995 (hp)

SAE J2723 33 - - 27

SAE J1940 -33 28 -

Measured

Maximum

Power

SAE J1995 (

hp)

SAE Certified Power 33.8 - - **

Measured by 3rd party -32.25 - -

Measured in house - - 28 -

Maximum Torque (ftlbs)50.1 51.1 -44.6

Bore –mm (in) 80 (3.15) 86 (3.39) 83.8 (3.30) 84.5 (3.33)

Stroke –mm (in) 82 (3.23) 71 (2.79) 73.4 (2.89) 76 (2.99)

Compression Ratio 9.1:1 8.9:1 8.4:1 8.2:1

Oil capacity (including filter)Not final na 2.1 qt.2.4 qt.

ENG configuration air cooled –vertical crankshaft

Lubrication full pressure with filter

4

499

464

639

*Competitor information from published public

data. Locations of measurements unclear.