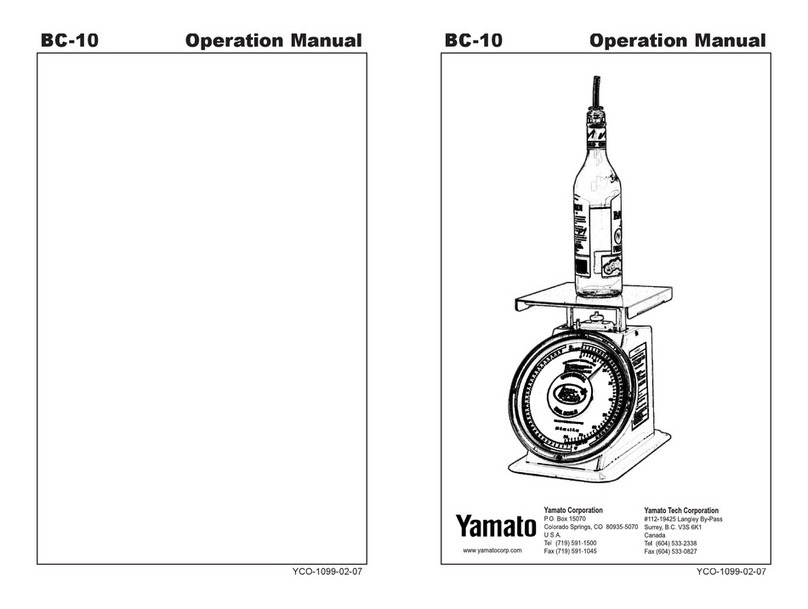

BC-10 Operation Manual BC-10 Operation Manual

YCO- 1099-04-02 YCO- 1099-04-02

bottle, the weight of the bottle needs to be known. The weight of the bottle is

the tare setting number. The simple step-by-step procedure to determine the

tare setting number is explained in detail on page 5. THIS IS A ONCE ONLY

OPERATION, as the tare setting number of each brand is recorded on the

initial Bar Inventory Worksheets, and is transferred onto the sucessive Bar

Inventory Worksheets. The same tare setting number is used over and over,

even though there are slight weight variations from bottle to bottle within the

same brand. These differences are negligible and average out. However,

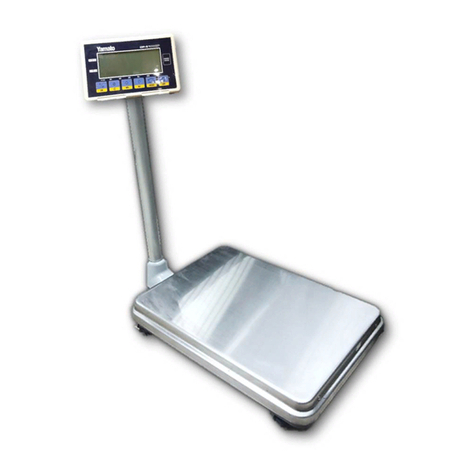

since the *Accu-weigh scale will be used for open bottles only, it is recom-

mended that a standard pourer be included in the tare setting number.

Otherwise, the pourer would have to be removed before inventory was taken.

To speed up the use of the scale while taking inventory, two columns are

provided on the Bar Inventory Worksheet where tare setting numbers are to

be entered according to the type of liquor to be weighed. The tare setting

number of bottles of distilled spirits are entered in the Bar Inventory

Wroksheet in the column marked “TARE (red grad).” In the column marked

“TARE (green grad.), the tare setting numbers of cordials/liquers should be

entered.

Once you have determined the sequence of inventory and established the

tare setting number for all of the brands that you normally carry in stock, you

are ready to start with your first inventory. The Bar Inventory Worksheets are

provided with columns where full bottles are recorded and a column where

the net contents of open bottles are entered. Any existing inventory method

can be used. For ease, and clarity, it is recommended that proper inventory

control worksheets are used, such as those provided with the scale. The

carefully designed worksheet supplies columns for all the necessary informa-

tion and allows inventory taking location by location, such as shelf 1, shelf 2,

etc. After each worksheet is completed, a grand total can be quickly ob-

tained by adding the totals of each worksheet.

Prior to taking an actual inventory, the Bar Inventory Worksheets should be

prepared in advance with with the tare setting numbers entered into the

proper columns. Two persons can most efficiently take inventory: one in

charge of the worksheets and the scale, the other in charge of the bottles.

Overview To Determine the Tare Setting Number

A. With an EMPTY bottle

The easiest way to determine the tare setting number of any brand is to weigh

an EMPTY bottle. If you have an empty bottle available, place it on the scale

and the indicator will show the tare setting number on the black graduations of

the fixed, inside chart. However, since the scale will be used to weigh open

bottles only, it is recommended to place, next to the empty bottle, a standard

pourer to be included in the tare setting number. This way, the pourer does not

have to be removed from the bottle when inventory is taken.

Record the tare setting number on the worksheet in the appropriate “TARE”

column.

B. OR with a FULL bottle

Place a full bottle on the scale with a standard pourer next to it. Using the

chart below, determine how many ounces are in the full bottle, and move the

outer ring to align the red value in ounces with the pointer. If, for example, it is

a quart of whisky, rotate the outer ring until the 32 fl. ounce mark of the red

graduations lines up with the indicator. Read the black graduation on the fixed,

inside chart, which is directly opposite the ZERO of the red graduations. This

number corresponding to this black graduation is the tare setting number.

Size of Bottle Number of Ounces

Fifth 25.6

Quart 32

Half Gallon 64

750 ml 25.4

1 liter 33.8

NOTE: The *Accu-weigh Bar Inventory Control Scale uses an exclusive set of

tare values which allow for the closest possible determination of the weight of

the glass bottle. The tare setting numbers are expressed in whole or half

numbers, such as 32, 32.5, 55.5, 60, etc., and should NOT be confused with

weight values taken from any other scale.

To Determine the Content of Open Bottles

A. The Bar Inventory Worksheet will determine the tare setting number to use.

If properly prepared, the worksheet will also show whether or not to use the red

or green graduations on the rotating outer ring.

How to Operate the BC-10

45