Contents

CONTENTS

INTRODUCTION ...............................................3

1 FOR YOUR SAFETY....................................4

1.1 Warning symbols................................

.4

1.2 Safety Precautions..............................4

1.3 Warning Labels ...................................

?

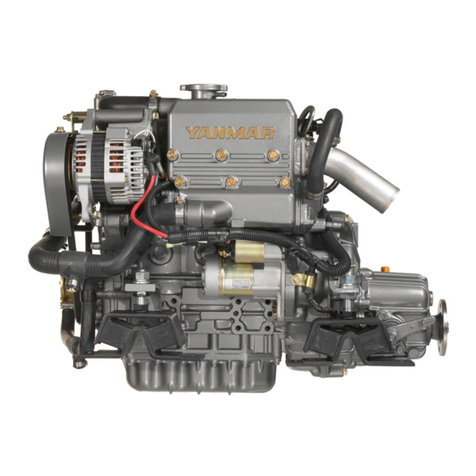

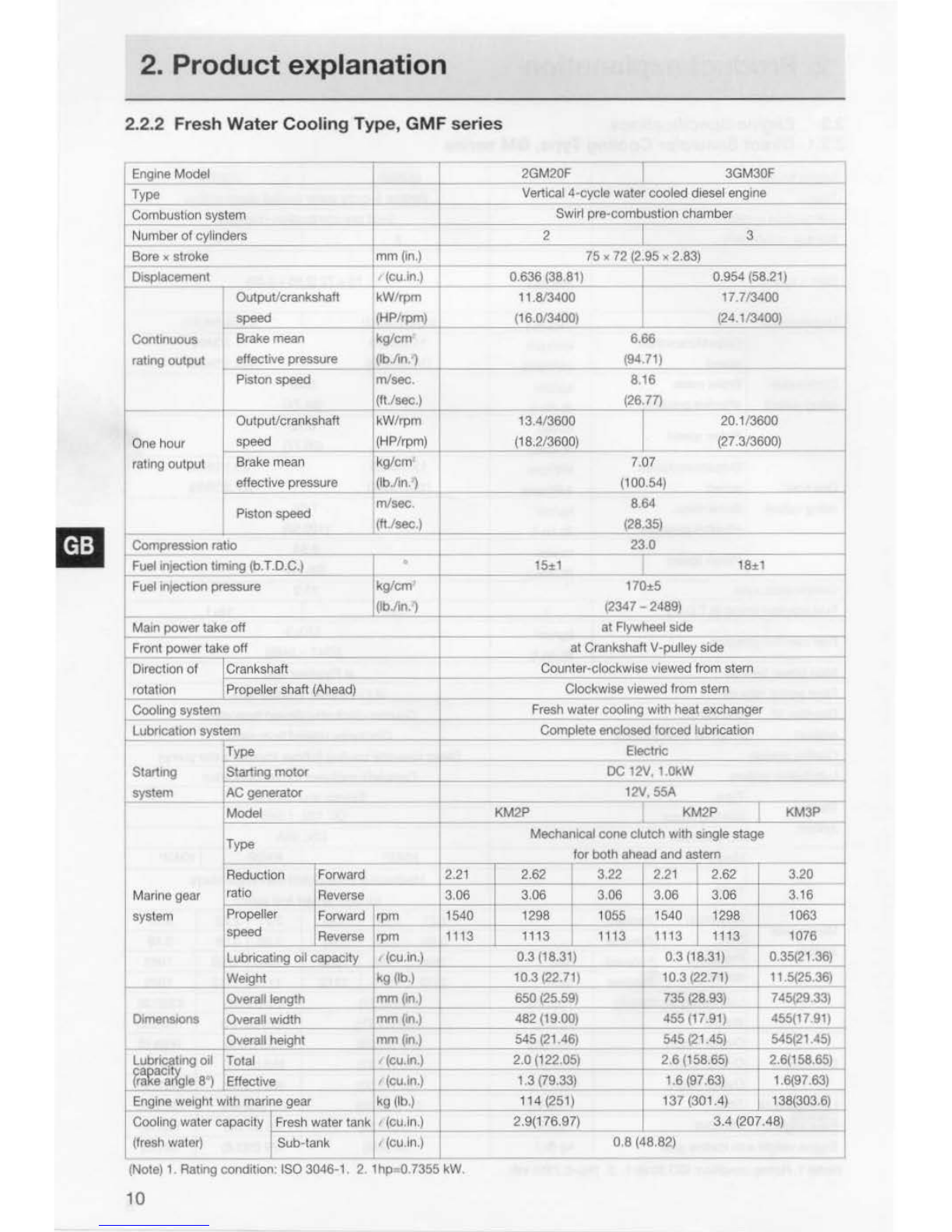

2 PRODUCT EXPLANATION..........................8

2.1

Use, Driving System etc......................8

2.2 Engine

Specif

i

cations

..........................9

2.3 N

ames

of

Parts..................................

15

2.4

Major

Servicing Parts........................

16

2.5 Control Equipment............................17

2

.5.1

Control Panel .......

..

.................17

2.5.2 Single Lever Remote

Control Handle..............

..

........

19

2.5.3 Stopping Equipment...............19

2.5.4 Decompression Equipment...

..

19

3 OPERATION..............................................20

3.1

Fuel

Oi

l, Lube Oil & Cooling Water....20

3.1.1 Fuel O

il

...............................

..

...20

3.1.2 Lube Oil...................................21

3.1.3 Cooling Water.........................

21

3.2 Before Initial Operation .....................

22

3.2.1 Supply Fuel

011

........................

22

3.2.2 Supply Engine Lube

011

...........22

3.2.3

Supply

C

lu

tch

Lube Oil ...........23

3.2.4 Supply Cooling Water.............23

3.2.5 Cranking (Idling) ......................

24

3.2.6 Check and Resupply Lube

Oil and

Coo

li

ng Water.............25

3.3 Operating

your

Engine ......................25

3.3.1 I

nspec

ti

on Before Starting......

26

3.3.2

How

to Start

the

Engine..........27

3.3.3 Operation ................................29

2

3.3.4 Cautions during Operation......30

3.3.5

Stopping

th

e Engine ...............30

3.4 Long term Storage............................32

4 MAINTENANCE& INSP

ECnO

N ...............34

4.1

General Inspection

Ru

l

es

..................34

4.2

Li

st

of

Periodic Inspection

lt

ems

.......35

4.3 Periodic Inspection ltems..................37

4.3.1 Inspection

on

Initial 50 Hrs.

of

Ope

ration (or after1 month)....37

4.3.2 Inspection Every 50 H

ours

(or monthl

y)

.............................37

4.3.3 Inspection Every 150

Hr

s ........39

4.

3.4

Inspecti

on

Every 300 Hrs........39

4.3.5 Inspecti

on

Every 600 Hrs........40

4.4

EPA

Requirements...........................

.41

4.4.1 EPA Certifi

ca

tion Plate............

41

4.4.2 Conditions to Insure

Compliance with Emission

Standards................................42

4.4.3 Inspection and Maintenance ...44

4.4.4 Emission System Warranty

Statement................................

44

5 TROUBLE AND TROUBLESHOOTING .....45

6 PIPING DIAGRAMS...................................48

7 WIRING DIAGRAMS..................................50

APPENDIX A (Piping diagrams).....................A-1

(See the b

ack

of

this Manual)

APPENDIX B (Piping diagrams) ....................B

-1

(See the

back

of

this Manual)