EF494T OM

3

BEFORE OPERATING

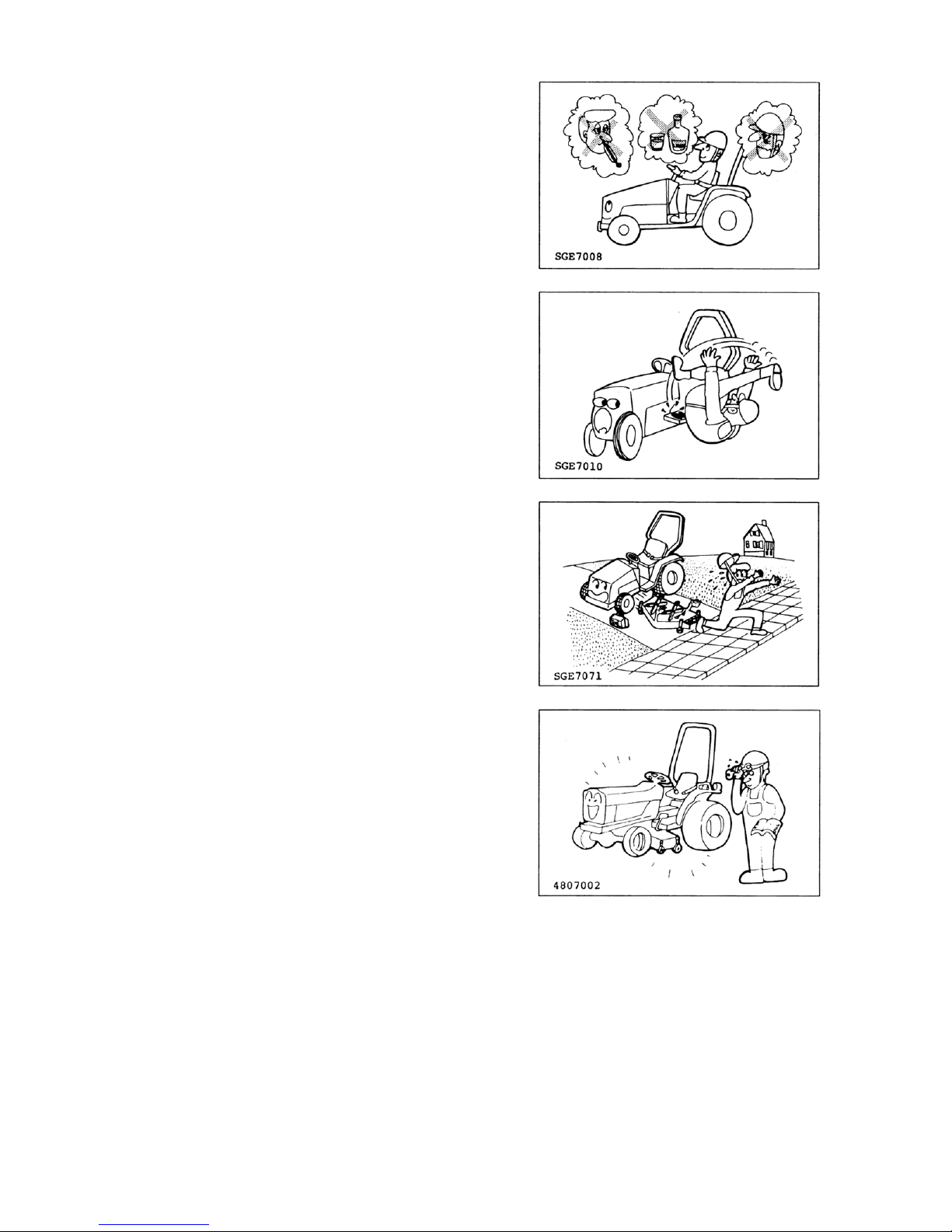

Do not operate the tractor when tired, sick, sleepy,

drunk, feeling overworked, taking medicine, pregnant,

suffering from mental disease or if other improper

conditions are present. These conditions impair a

person’s skill and judgment. When you begin feeling

tired while operating the tractor, take a 10-minute break

to stretch, walk about, lie down or snack. Do not

continue if you still feel tired after taking a break.

Remove oil, grease or mud from the hand rails, steps,

pedals, controls, and floor to avoid slips or loss of

control.

In winter, scrape off any ice or snow on the handrails,

steps, pedals, controls, and floor.

To attach or remove an implement, refer to the

implement and tractor manufacturer’s manuals for the

proper procedures.

To unhitch an implement, move to a level area, lower the

implement to the ground and then block the equipment

in position before unhitching. If an implement has

wheels, block them to prevent it from rolling.

Make sure

(1) The tractor and implements are in good condition

and properly adjusted.

(2) To check for loosened bolts, adequate lubricants,

damaged or under-inflated tires, safety shields and

devices, steering and braking linkages, hydraulic

leaks, etc. Refer to this manual for more detailed

information.

(3) That implements are properly attached and hooked

up. Check that the PTO U-joint yoke and locking

devices are securely latched on their shafts.

(4) That the tractor’s PTO speed matches the

implement’s specifications.