Safety

Instructions

5

13. When using a heavy implement on 3point

hitch, always install front ballast for stability

and steeringcontrol.

14.

Too large an implement

is

dangerous for

tractor operation. Refer to your implement

operator's manual for minimumand maximum

horsepower requirement.

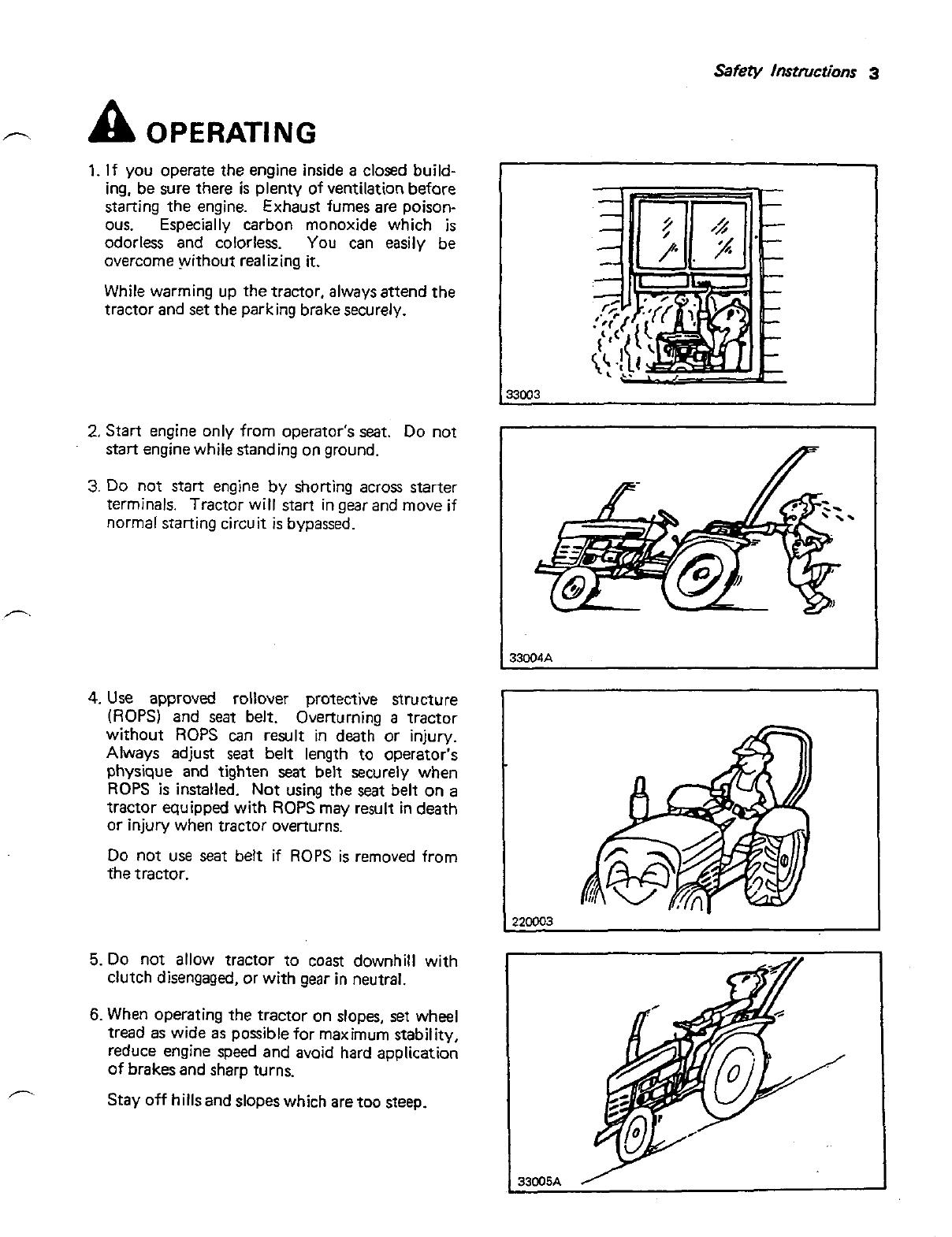

15. Do not pull carts etc. from the top link or top

link hinge, the rear axleor any pointabove the

drawbar. Doing so could cause the tractor tip

over rearward. For pulling, attach carts etc. to

the drawbar only.

Use care when pulling loads or using heavy

implement.

1) Use only approved hitchpoints.

2) Limit loadsto those you cansafely control.

3) Don't turn too sharp, and care when back-

ing.

4)

Use counterweight or wheel weights when

suggested inoperator's manual.

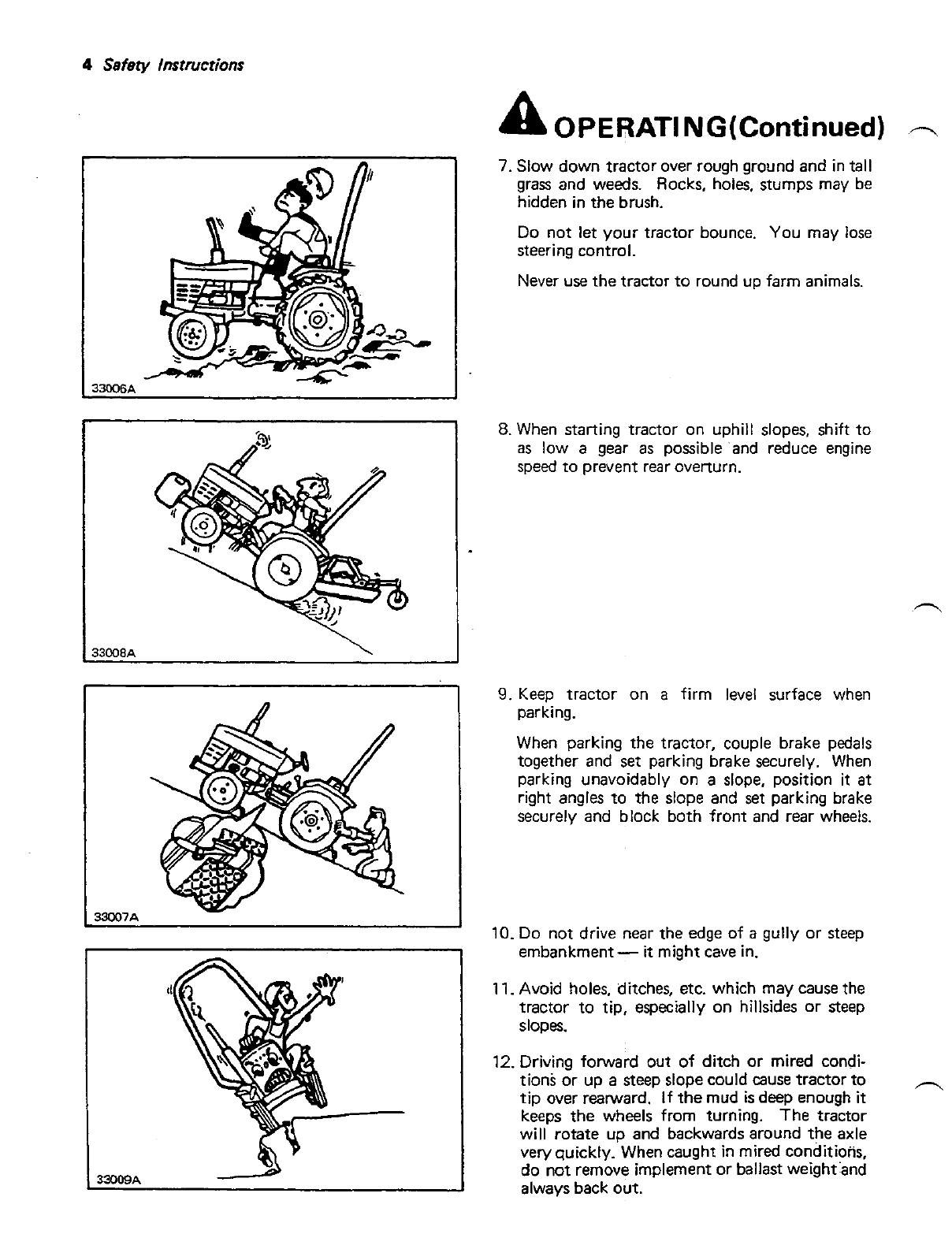

16.Take all possible precautions as follows when

leavingtractor unattended:

a) Disengage PTO.

b)

Lower implementtoground.

C)

Shift allshift leversto neutral.

dl Latch power shift lock lever. (Power shift

transmission only)

e) Couple brake pedals together and set park-

ingbrake lever.

f)

Run engine to cool for 2 to 3 minutes at

onethirdthrottle speed and no load.

g) Stop engine.

h) Cycle hydraulic controls to eliminate

residualpressure.

il

Removekey.

When you leaveoperator's seat, wait forengine

and implementpartstostop moving.

17.

Do not permit any personother than operator

to ride or board on tractor or implements

includingwagons.

Never allowchildren in.thetractor

cab

or allow

them to rideon your lap.

Nwer allow anyone to stand on the overhead

guard or fenders.

Donot "cowboy" or playgames withatractor.