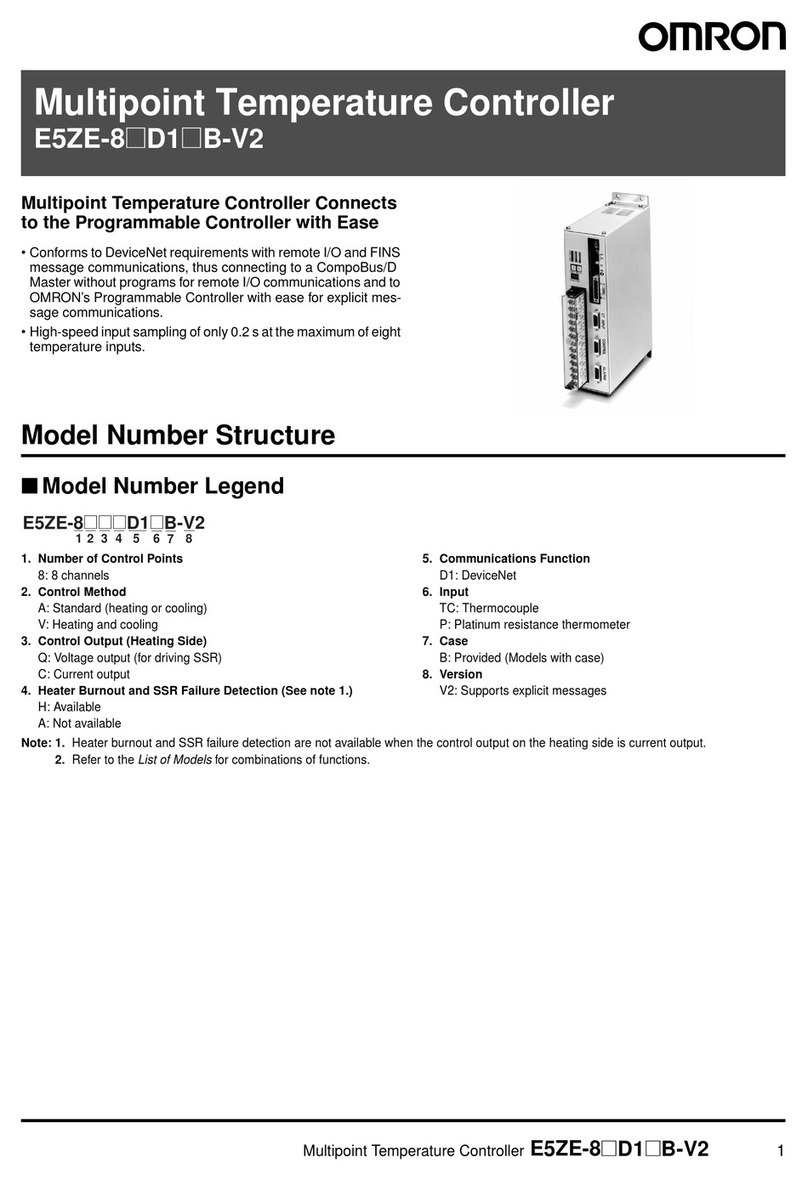

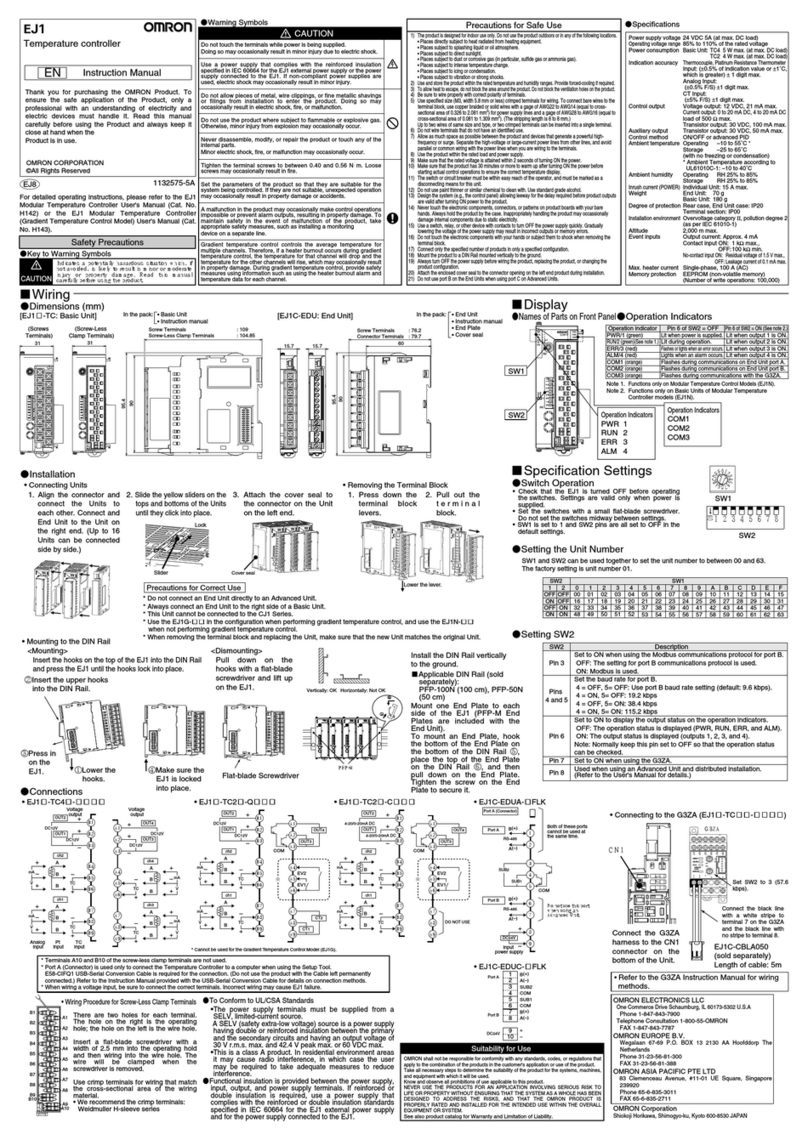

EJ1

7

Ratings

Characteristics

Communications Characteristics

*For the number of Units that can be connected, refer to “Connection Precautions” on page 11.

HFU Unit/EJ1N-HFUB-DRT

Power supply voltage DeviceNet power supply 24 VDC (for internal circuits)

EDU power supply 24 VDC (for RS-485 communications circuits and Temperature Controllers)

Operating voltage

range

DeviceNet power supply 11 to 25 VDC

EDU power supply 20.4 to 26.4 VDC

Power consumption (at maximum load) 1 W max. (at maximum load)

Main functions Remote I/O communications, explicit message communications, CompoWay/F command feed-through

function, parameter backup function, and configuration registration

Ambient temperature range Operating: −10°C to 55°C

Storage: −25°C to 65°C (with no icing or condensation)

Ambient humidity range Operating: 25% to 85% (with no condensation)

Insulation resistance 20 MΩmin. (at 500 VDC)

Dielectric strength 600 VAC, 50/60 Hz for 1 min

Vibration resistance 10 to 55 Hz, 10 m/s2for 2 hours each in X, Y, and Z directions

Shock resistance 150m/s2max. 3 times each in 3 axes, 6 directions

Weight 70 g max.

Degree of protection IP20

Memory protection EEPROM, 100,000 write operations (backup data)

Standards Approved standards UL61010-1, CSA C22.2 No.1010-1

Conformed standards EN61010-1 (IEC61010-1): Pollution level 2, overvoltage category II

EMC Directive Refer to page 3.

Communications protocol Conforms to DeviceNet.

Communications

functions

Remote I/O

communications

Master-slave connections (polling, COS, or cyclic)

Conforms to DeviceNet specifications.

I/O allocation

Input and output data can be allocated freely by user with the Configurator.

Allocations can be made to DeviceNet parameters or Temperature Controller parameters.

Two blocks for IN Area, up to 100 words

One block for OUT Area, up to 100 words (The first word is always allocated to the OUT Enable Bit.)

Message communications Explicit message communications

CompoWay/F communications commands can be sent (commands are sent in explicit message format).

Connection format Combination of multidrop and T-branch connections (for trunk and drop lines)

Baud rate DeviceNet: 500, 250, or 125 kbps, or automatic detection of master baud rate

Communications media Special 5-wire cable (2 signal lines, 2 power lines, and 1 shield line)

Communications distance

The values in parentheses apply when Thin Cables are used.

Communications power supply 11 to 25 VDC

Maximum number of nodes that can be connected 64 (includes Configurator when used.)

Maximum number of slaves that can be connected 63

Error control CRC error detection

DeviceNet power supply Power supplied from DeviceNet communications connector

Applicable Temperature Controllers

EJ1 Series (excluding the EJ1G)

TC4: EJ1N-TC4A-QQ and EJ1N-TC4B-QQ

TC2: EJ1N-TC2A-QNHB, EJ1N-TC2B-QNHB, EJ1N-TC2A-CNB, and EJ1N-TC2B-CNB

Maximum number of Temperature Controllers that

can be connected *16 Units (model numbers with TC4: 64 channels max., model numbers with TC2: 32 channels max.)

Baud rate Network length Drop line length Total drop line length

500 kbps 100 m max. (100 m max.) 6 m max. 39 m max.

250 kbps 250 m max. (100 m max.) 6 m max. 78 m max.

125 kbps 500 m max. (100 m max.) 6 m max. 156 m max.