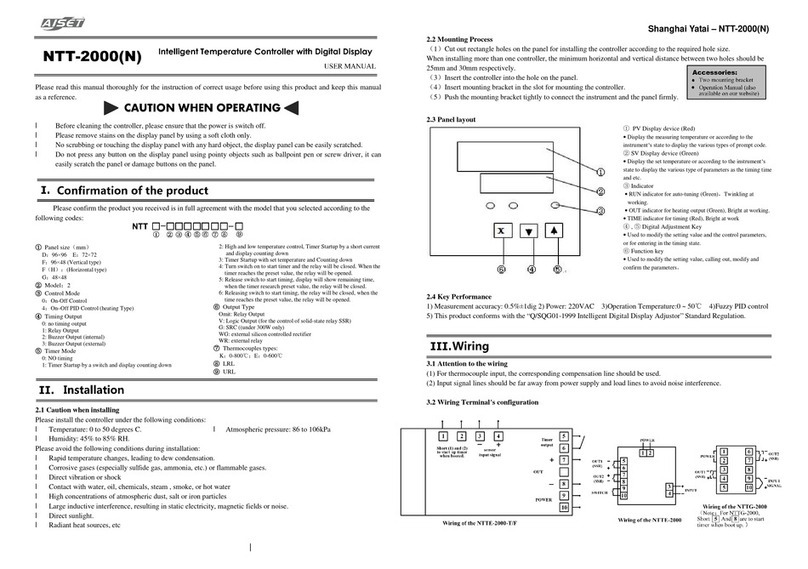

NTTF/H-3000

Settingofthetemperature:PushthekeyX, theupper row displaysthevalueofSP and push orkeytomakethe

lower row displayitsneededvalue.Andpushthe keytopromotethesystemtotheSTsettingmode.

SettingofTiming: Theupper row displaysSTandpush orkeytomakethelower row displaytheneededvalue.

Againpushthe keytopromotethesystem returntoitsstandardmode.

Settingofthecontrol parameters:Pushthe keyabove4seconds,theupper row shows thepromptcodeofthe

parameter(detailcansee thescheduletableofthecontrol parameters)andthanpush orkeytomakethelower row

displayitsneededvalue. Continuepushthe keycanmaketheupper row displaythepromptcodeofeachofanother

parameterinturn. Againpush orKeytoupdatethevalueofparametertoitsneededvalue, andagainpush theX

keyabove4seconds,thesystemreturnsbacktoitsstandardmode. (If nokeyhaspusheddown,after 1minutethe

systemwill cometoitsstandardmode).

If under thereddisplaythe “ooo”isappeared,thethermocoupleisinreverseconnection,elseabovethereddisplay

the “ooo”isappeared,thethermocoupleisinopencurrentorthemeasuringtemperatureexceedsthemeasurement

range.

TheAuto-tuningfunction oftheinstrument’sparameters:After20 secondsofpushingdownthe key, theAT

indicatoristwinkleandthecontroller beginstostartitsAuto-tuning. Thetemperature goesthroughonetotwo timesof

oscillationandtheAT indicatorextinguishes. Theinstrumentwill control theprocesswiththeupdatedparameters,

whichwill bepermanentlypersevered.

TheswitchfunctionofCelsiusandFahrenheittemperature:Hold downthekey orsimultaneously, theupper

row showsLK, againpushtheXkeytoprompttheupperrow appearsSnandlower row appearsK-C(Celsius

temperature) orK-F (Fahrenheittemperature)andpush or keytocarryoutthetransform ofthescaleof

temperature.

Selectionofthemeasurementrange:Holddown thekey orsimultaneously, theupper row showsLK, again

pushtheXkeytoprompttheupper row appearsrLandlower row appears0, and againpushXkeytomaketheupper

row appearrH,atthattimetherowerrowappearstheneededmeasurementrange.

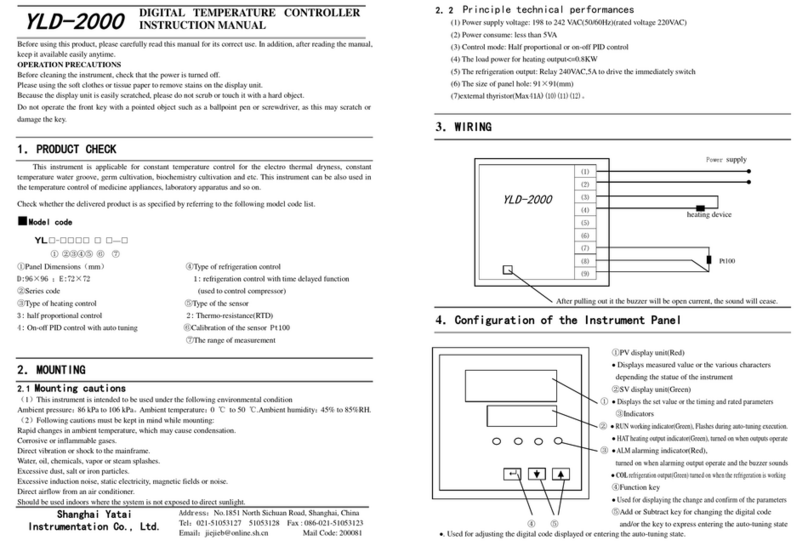

4.2The scheduletableofthe control parameter

Prompt

Symbol

Name Setting

Range

Illustration

Value

SettingofAlarm -199…

Range

SettingofAlarm 1,Insensitiveintervalofalarm isequaltoa

constantvalue0.4(Thisvalueismeaningless) 50or50.0

AL1

Proportionalband

(HeatingSide)

ProportionalControl: ThemorethevalueofP,thelessthe

proportionalactionandthelessthesystemgain;onlyactingonthe

heatingside.(P=0isON/OFF Control) 30

P

IntegralTime 0…990

Seconds IntegralTime:Themore thevalueofI, thelesstheIntegralaction

I=0 isPDControl,Ar= RemainedError/P)×100 240

I

DifferentialTime

0…990

seconds Differentialtime:ThemoretheValueofD,themorethedifferential

action, whichisabletoovercome overshoot(D=0isPIControl) 60

D

-setting)

ON/OFF Control)

0~100%

UsedtorestrainOvershoot (Arissetto1.5~

ratioin thesteadystateofthesystem)

ReduceArenergyandtemperatureovershoot, whenSP ischanging,

Armustbeadjusted;Armustbeconfirmedandwill besetaccording

toSPvalueautomatically.

100

Ar

Control period

HeatingSide)1…100

Seconds

Whentherelayoutput20s,SSRandSi≮-controlledswitch

transwitch2s,continuousoutputTisequalto1s,onlyactingon≮

heatingside 20

T

Value -198…

998℃Usingforcorrectthemeasurementerrorcausedbythesensorandthe

compensatelineofthethermocouple 0

Pb

Time control mode 0~16

0or10:whenswitchison,displaywill startcountingdownto0.

Whentherelayis closed,thealarm will beturnedonuntilthe

switchisoff and therelayisopen. Thealarm shall stoptocomplete

onecycleofoperation.

1or11:whenswitchison,displaywill startcountingdownto0as

relayis closed. Whenrelayis open,thealarm will beturnedon

untiltheswitchisoff. Thealarmshall stoptocompleteonecycle

ofoperation;

2or12:High andlow temperature control. Outputwill besetwhen

thetemperatureisbelow thepresetvalue. Outputwill bereset

whenthepresetvalueisreached. WhenthetemperatureofON

switchisbelow thanthehigh temperaturepresetvalue, outputwill

beset.Whenthehightemperaturepresetvalueisreached,output

will beresetandthecountingdownwill start.

3or13:Switchontostartcountingdown. Therelayisclosedor

thealarmison whenremainingtimeis0untilithasbeenswitch

offandonagain. Once switchiscycled,therelaywill beopened

andthealarmwill bestoppedtocompleteonecycleofoperation.

4or14:Switchontostartcountingdownandtherelaywill be

closed. Whenremainingtime is0,therelaywill beopenedorthe

alarm will beturnedon.Cycleandholdonswitchtocompleteone

cycleofoperation.

5or15:Switchon andoff tostartcountingdown, whenremaining

time is0,therelaywill beclosedorthealarm will beturnedon.

Therelaywill openorthealarmisoff untilthenexttimerelease

theswitchtostarttocompleteonecycleofoperation.

6or16:Releasingswitchtostartcountingdown,therelaywill be

closedorthealarmwill beturnedon.Whenremainingtime is0,

therelayisopenandonecycleofoperation iscompleteduntilthe

nextreleaseoftheswitchtostart,therelaywill beclosedandthe

alarm will bestopped.

Others:not applicable;

Note:whenthedigitsegmentof10sisone,mutethedevice by

pressanykey.

0

Run

codedlock 0,1,2

0:All parameterscanbeupdated

1:OnlytheSetPointValuecanbeupdated

2:All parameterscannot beupdated. 0

LCK

Notice: Changeofeachfunctionparameter inthetablemayalter thecontrol effectofthesystem.

Thiscontroller isunder warrantyfor12monthssincethedayofpurchase(thewarrantyonlystandsiftheproblem is

causedbythemalfunction duetomanufacturing). Anyrepairmentfordamagescausedbyimproper useofthecontroller

will becharged. Thecontroller isprovidedwithlifetimemaintenance andrepaironcost.

Pleasekeepthecontroller inadryplace withairandNO corrosivegas.