Pleasereadthismanualthoroughlyforthe instructionof correctusagebeforeusingthisproductandkeepthis

manualasareference.

lBefore cleaningthecontroller, pleaseensure thatthepower isswitchoff.

lPleaseremovestainson thedisplaypanelbyusingasoftclothonly.

lNo scrubbingortouchingthedisplaypanelwithanyhardobject,thedisplaypanelcanbeeasilyscratched.

lDo notpressanybuttonon thedisplaypanelusingpointyobjectssuchasballpointpenorscrewdriver,it

caneasilyscratchthepanelordamagebuttonsonthepanel.

Pleaseconfirmtheproductyoureceivedisinfull agreementwiththemodelthatyouselectedaccordingtothe

followingcodes:

Panel Dimensions mm)

D:96 96 F:96 48

E:72 72 G:48 48

T②ype of Display

6: Double rows display

Type of control action③

0: On-offaction Relay 3: Timeproportion action

4: On-offPIDaction with auto-tuning

7: Single phase zero-across pulse PIDaction with auto-tuning

On④-offposition Alarm

0: No alarm1: Highalarm

Type of Input⑤

1: Thermocouple signal

2: Thermo-resistance signal (RTD input)

Type of Output⑥

No: Relay contact (Maximum3A)

V:Logic output for SSR

A:Relay contact (Maximum16A)

B: Relay contact (Maximum16A)

Type of ca⑦libration

Lower limit of the span⑧

Upper limit of the span⑨

2.1Cautionwhen installing

Pleaseinstall thecontroller underthefollowingconditions:

lTemperature:0to50degreesC.

lHumidity:45%to85%RH.

lAtmosphericpressure:86to106kPa

Pleaseavoidthefollowingconditionsduringinstallation:

lRapidtemperaturechanges, leadingtodewcondensation.

lCorrosivegases(especiallysulfidegas,ammonia, etc.)orflammablegases.

lDirectvibrationorshock

lContactwithwater,oil,chemicals,steam,smoke, orhot water

lHighconcentrationsofatmosphericdust, saltorironparticles

lLargeinductiveinterference, resultingin staticelectricity, magneticfieldsornoise.

lDirectsunlight.

lRadiantheatsources,etc

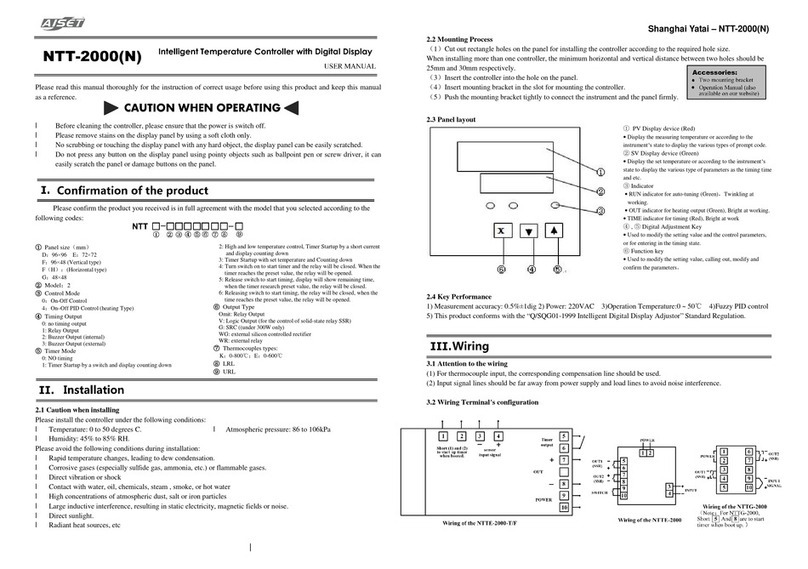

2.2MountingProcess

1)

Cutoutrectangleholesonthepanelforinstallingthecontroller accordingtotherequiredholesize.

Wheninstallingmorethanonecontroller,theminimumhorizontalandverticaldistancebetweentwo holesshould be25mm

and30mmrespectively.

2)Insertthecontroller intotheholeonthepanel.

3)Insertmountingbracketintheslot formountingthecontroller.

4)Push themountingbrackettightlytoconnecttheinstrumentandthepanelfirmly

2.3Dimension in millimeters

Hh Model H×B h×b×L h’×b’

ND 96×96 92×92×70 (92+1)×(92+1)

BL NE 72×72 68×68×70 (68+1)×(68+1)

bb' NF 96×48 92×44×70 (92+1)×(44+1)

NG 48×48 44×44×100 (44+1)×(44+1)

h'

31Wiringcautions

1)Forthermocoupleinput,usethespecifiedcompensationwire.

2)ForRTD input,useleadswithlow resistanceandhavingnoresistancedifferencesamongthe3leads.

3)Conductinputsignalwiringawayfrominstrumentpower,electricequipmentpower andloadlinesto

avoidnoiseinduction.

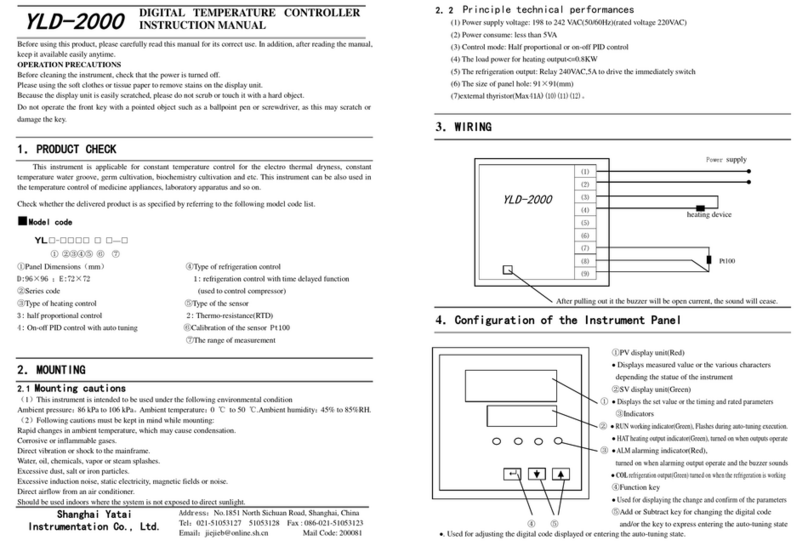

32Terminals'configuration

1)TerminalsforModel: 2)Terminals forModel(withSSR):

ND/F/E-6011,6311,6411,6012,6312,6412 ND/F/E-6401V,6401V,6302V,6402V