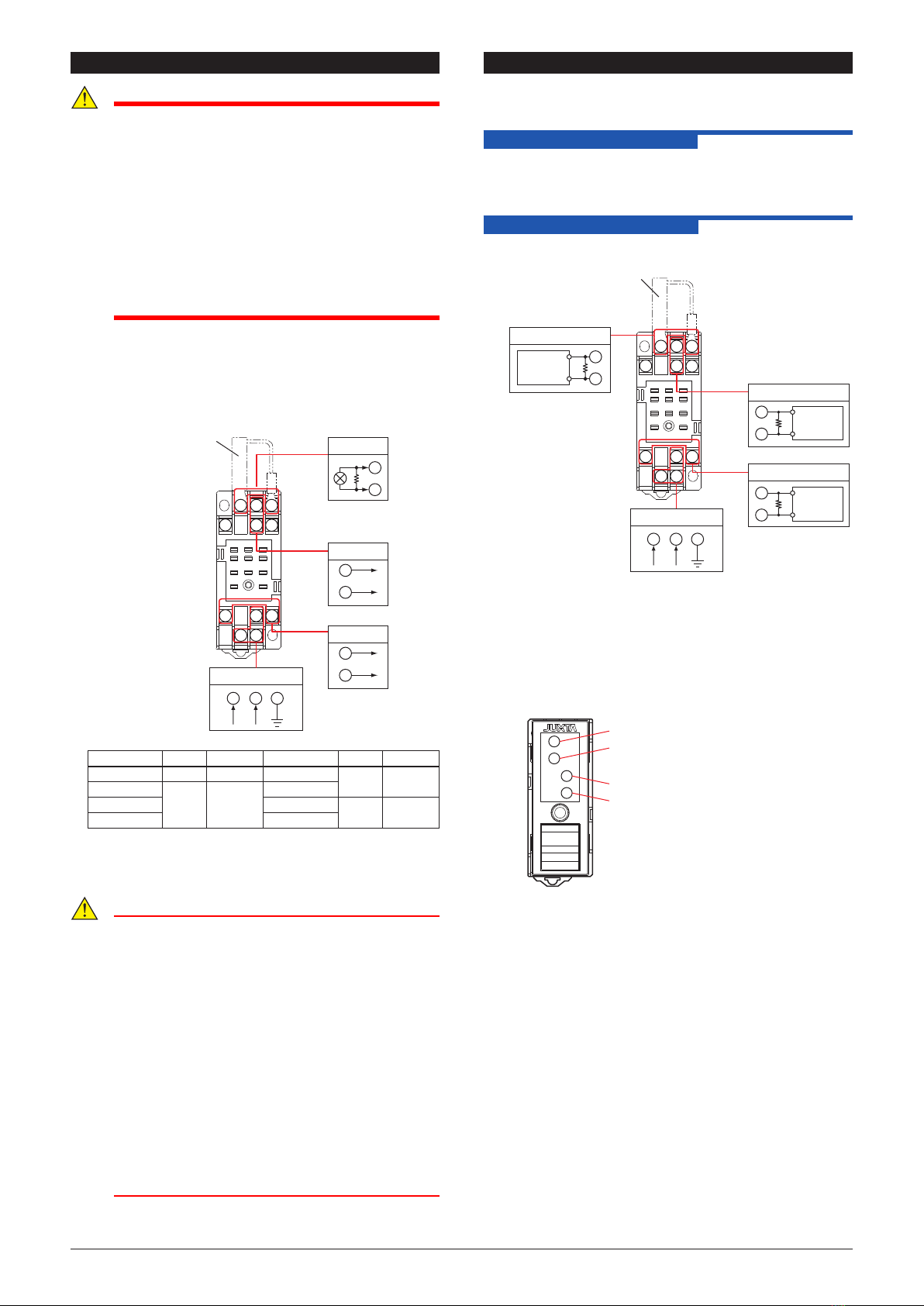

3. EXTERNAL WIRING

WARNING

●To avoid the risk of an electric shock, turn o the

power supply and use a tester or similar device to

ensure that no power is supplied to a cable to be

connected, before carrying out wiring work.

●Do not operate the product in the presence of

ammable or explosive gases or vapors. To do so

is highly dangerous.

●Use of the product ignoring the specications may

cause overheating or damage. Before turning on

the power, ensure the following:

•Power supply voltage and input signal value

applied to the product should meet the required

specications.

•The external wiring to the terminals and wiring to

ground are as specications.

Wiring should be connected to the terminals on the socket of

the product. The terminals for external connections are of M3

screws. Use crimp-on terminal lugs for connections to the

terminals.

• Recommended cables: A nominal cross-sectional area of 0.5

mm2 or thicker for signal cables, and that of 1.25 mm2 or

thicker for power cables.

1011

3 2 1

4

56

789

10 to 50 mA DC

4 to 20 mA DC

0 to 20 mA DC

0 to 16 mA DC

100 Ω

250 Ω

E9786WD

E9786WE

2 to 10 mA DC

0 to 10 mA DC

1 to 5 mA DC

0 to 1 mA DC

500 Ω

1 kΩ

E9786WF

E9786WG

<External Receiving Resistor (Shunt Resistor) for Current Input>

Resistance

Part No. Input ragneInput ragne

Resistance

Part No.

1110 8

L+ N– GND

7

9

+

–

2

1

3

5

+

–

+

–

Ri

Power Supply

Output-1

Output-2

Input signal

External receiving resistor

(Shunt resistor)

for current input (Note)

Ri

: External receiving resistor

for current input

(Note)

(See the table below.)

Note: Option code /C and /HC have a built-in receiving

resistor. An external receiving resistor is not

required.

CAUTION

●Do not use output-2 for the isolated single-output

type.

●The power line and input/output signal lines should

be installed away from noise-generating sources.

Other wise accuracy cannot be guaranteed.

●Make sure to earth ground the ground terminal

through minimum resistance. The length and

thickness of the grounding cable should be as

short and thick as possible. Directly connect the

lead from the ground terminal (terminal no. 8) of

the product to the ground. Do not carry out daisy-

chained inter-ground terminal wiring.

●The product is sensitive to static electricity;

exercise care in operating it. Before you operate

the product, touch a nearby metal part to discharge

static electricity.

●If the ambient temperature is 50 °C or more, please

use the cable that the rated temperature is 70 °C or

more.

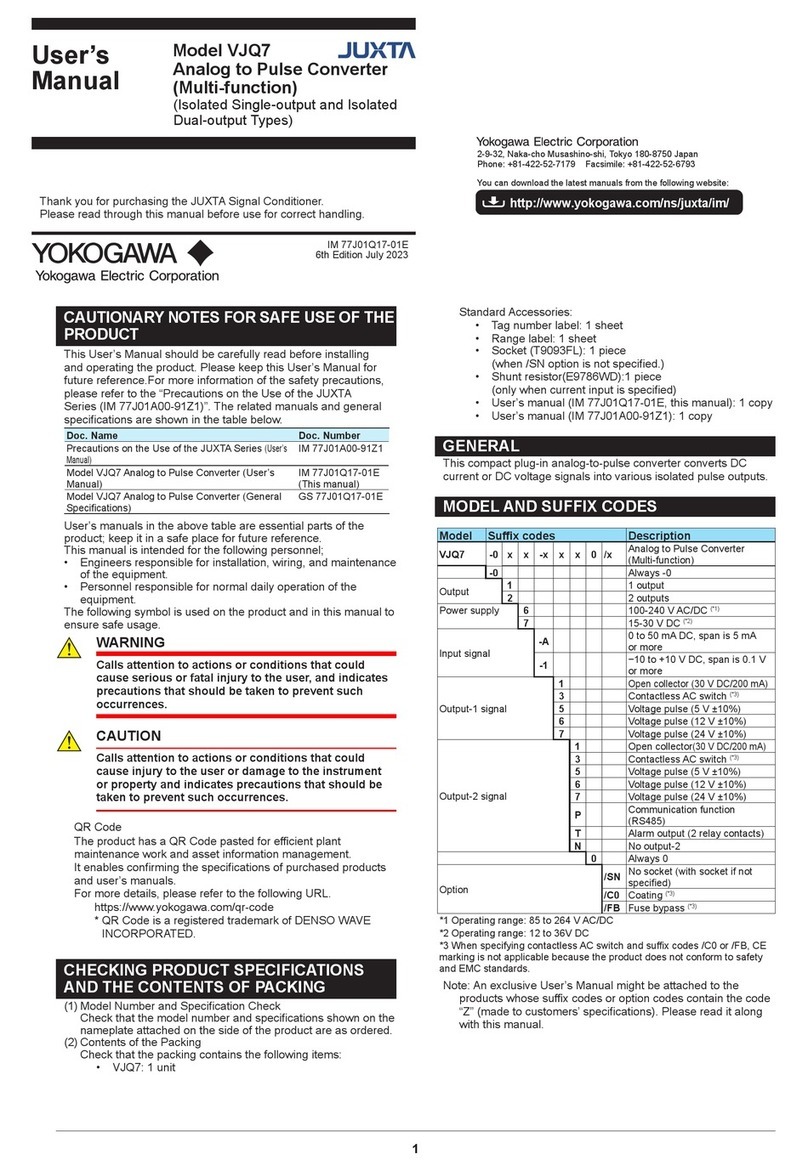

4. MAINTENANCE

The product starts running immediately when the power is turned

on; however, it needs 10 to 15 minutes of warm-up before it

meets the specied performance.

4.1 Calibration Apparatus

• A DC voltage/current standard (YOKOGAWA GS200 or the

equivalent)

• A digital multimater (YOKOGAWA DM7560 or the equivalent)

• A precision resistor of 250 Ω ± 0.01%, 1 W

4.2 Calibration Procedure

1. Connect the instruments as shown below. First adjust the

output-1 signal and then the output-2 signal.

1011

3 2 1

4

56

789

External receiving resistor

(Shunt resistor)

for current input

1110 8

L+ N- GND

Ri

1

3

2

5

Ro -

+

-

+

-

+

7

9

Ro

Ri: External receiving resistor

for current input

(See chapter 3.)

Power supply

Output-2

Input

Output-1

Ro: 250 Ω

for current output

DC voltge/

current

standard

Digital

multimater

Digital

multimater

For option codes /C and /HC,

do not attach an external

receiving resistor.

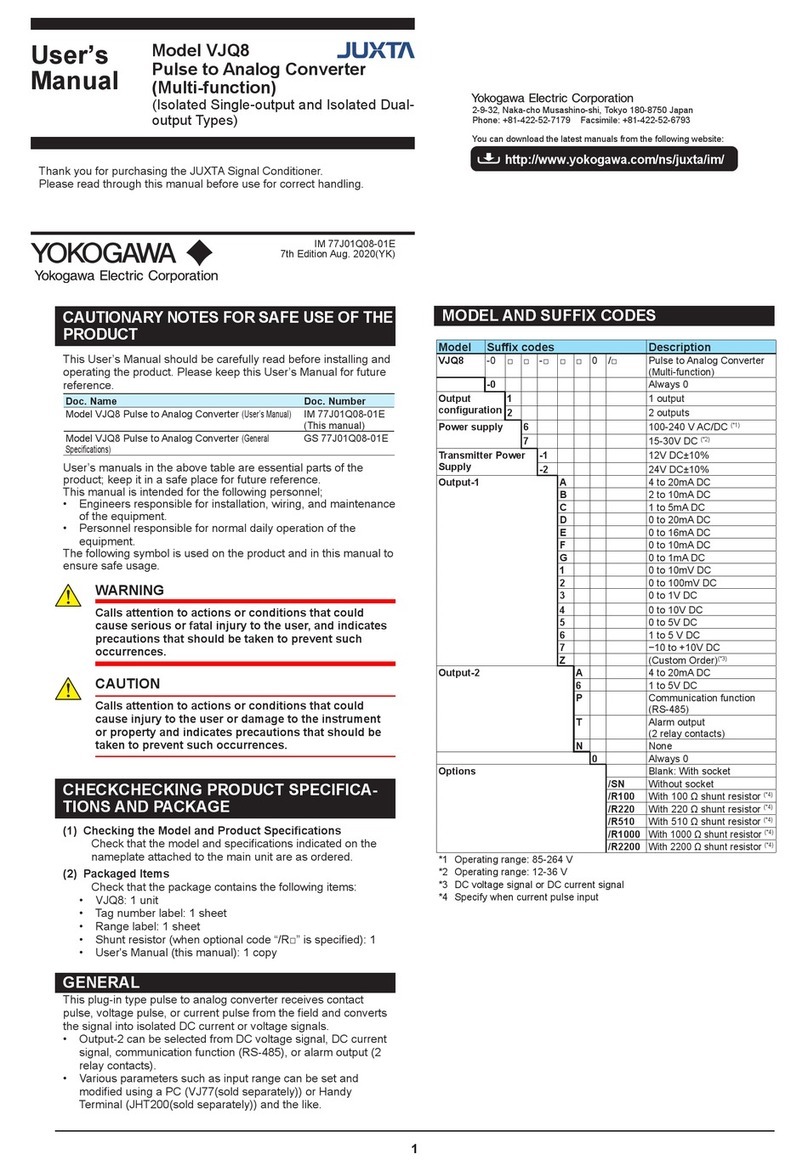

2. Use the DC voltage/current standard and apply input signals

equivalent to 0, 25, 50, 75, and 100% of the input span to the

product.

3. Check to see the corresponding output voltages are 0, 25, 50,

75, and 100% respectively and within the specied accuracy

rating. “R” is used for current output.

• If the output signals are out of the accuracy rating range,

adjust the output signal level using the zero and span

adjustment volumes on front face of the product.

Zero-adjustment volume

Output-1

Span-adjustment volume

Zero-adjustment volume

Output-2

3IM 77J01H01-01E 7th Edition