JOHNSON CONTROLS

8

FORM 160.76-N1

ISSUE DATE: 06/21/2019

SECTION 1 - INTRODUCTION

• Do not charge the compressor with oil.

• Do not charge the unit with refrigerant.

• Do not attempt to start the system.

• Do not run hot water (110°F / 43°C max) or steam

through the evaporator or condenser at any time.

SHIPMENT

The chiller may be ordered and shipped in any of the

following forms:

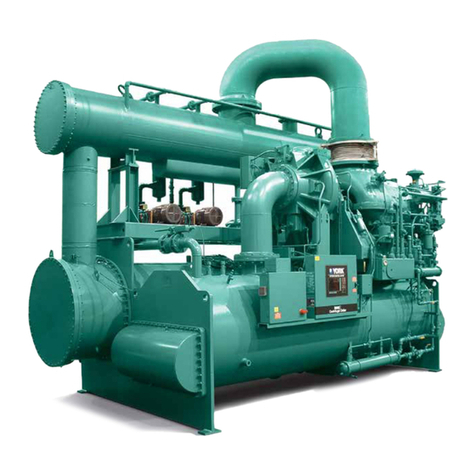

Form 1 – Factory Assembled Unit, complete with mo-

tor, refrigerant and oil charges.

• The motor/compressor assembly mounted,

with all necessary interconnecting piping

assembled. OptiView™ Control Center is

mounted on the unit. Complete unit factory

leak tested, evacuated and charged with

refrigerant.

An optional Solid State Starter or Variable

Speed Drive can be factory mounted and

wired.

• Miscellaneous material – Four (4) vibration

isolation pads (or optional spring isolators

and brackets). K7 units are shipped with 8

Vibration Isolation Pads.

Form 2 – Factory Assembled Unit, complete with mo-

tor (refrigerant and oil charges shipped sepa-

rately).

• The motor/compressor assembly mounted,

with all necessary interconnecting piping

assembled. OptiView™ Control Center is

mounted on the unit. Complete unit fac-

tory leak tested, evacuated and charged with

holding charge of nitrogen.

An optional Solid State Starter or Variable

Speed Drive can be factory mounted and

wired.

• Miscellaneous material – Four (4) vibration

isolation pads (or optional spring isolators).

K7 units are shipped with 8 Vibration Isola-

tion Pads.

Form 3 – Driveline Separate From Shells – Shipped as

two major assemblies. Unit first factory assem-

bled, refrigerant piped, wired and leak tested;

then dismantled for shipment.

• Compressor/motor assembly removed from

shells and skidded. Evaporator/condenser is

not skidded.

• All wiring integral with compressor is left on

it, and all conduit is left on shell. All open-

ings on compressor, oil separator, and shell

are closed and charged with dry nitrogen

(2 psig to 3 psig) (115/122 kPa).

• Miscellaneous packaging of control center,

tubing, water temperature controls, wiring,

oil, isolators, solid state starter (option), and

so on. The refrigerant charge is shipped sepa-

rately.

Units shipped dismantled MUST be re-

assembled by, or under the supervision of,

a Johnson Controls representative. Refer

to Installation - Unit (Form 160.76-N3)

Form 7 – Split Shells – Shipped as three major assem-

blies. Unit first factory assembled, refriger-

ant piped, wired and leak tested; then dis-

mantled for shipment.

• Compressor/motor assembly removed from

shells and skidded.

• The evaporator and condenser shells are sep-

arated at tube sheets and are not skidded. The

refrigerant lines between shells are flanged

and capped, requiring no welding.

• All wiring integral with compressor is left on

it. All wiring harnesses on the shells are re-

moved. All openings on the compressor and

shells are closed and charged with dry nitro-

gen (2 psig to 3 psig) (115/122 kPa).

• Miscellaneous packaging of control center,

tubing, water temperature controls, wiring,

oil isolators, solid state starter (option), etc.;

refrigerant charge shipped separately.

Units shipped dismantled MUST be re-

assembled by, or under the supervision of,

a Johnson Controls representative. Refer

to Installation - Unit (Form 160.76-N3)

When more than one chiller is involved, the major

parts of each unit are marked to prevent mixing of as-

semblies. (Piping and Wiring Drawings to be furnished

by Johnson Controls)