JOHNSON CONTROLS

6

FORM 160.67-PW7

ISSUE DATE: 2/28/2019

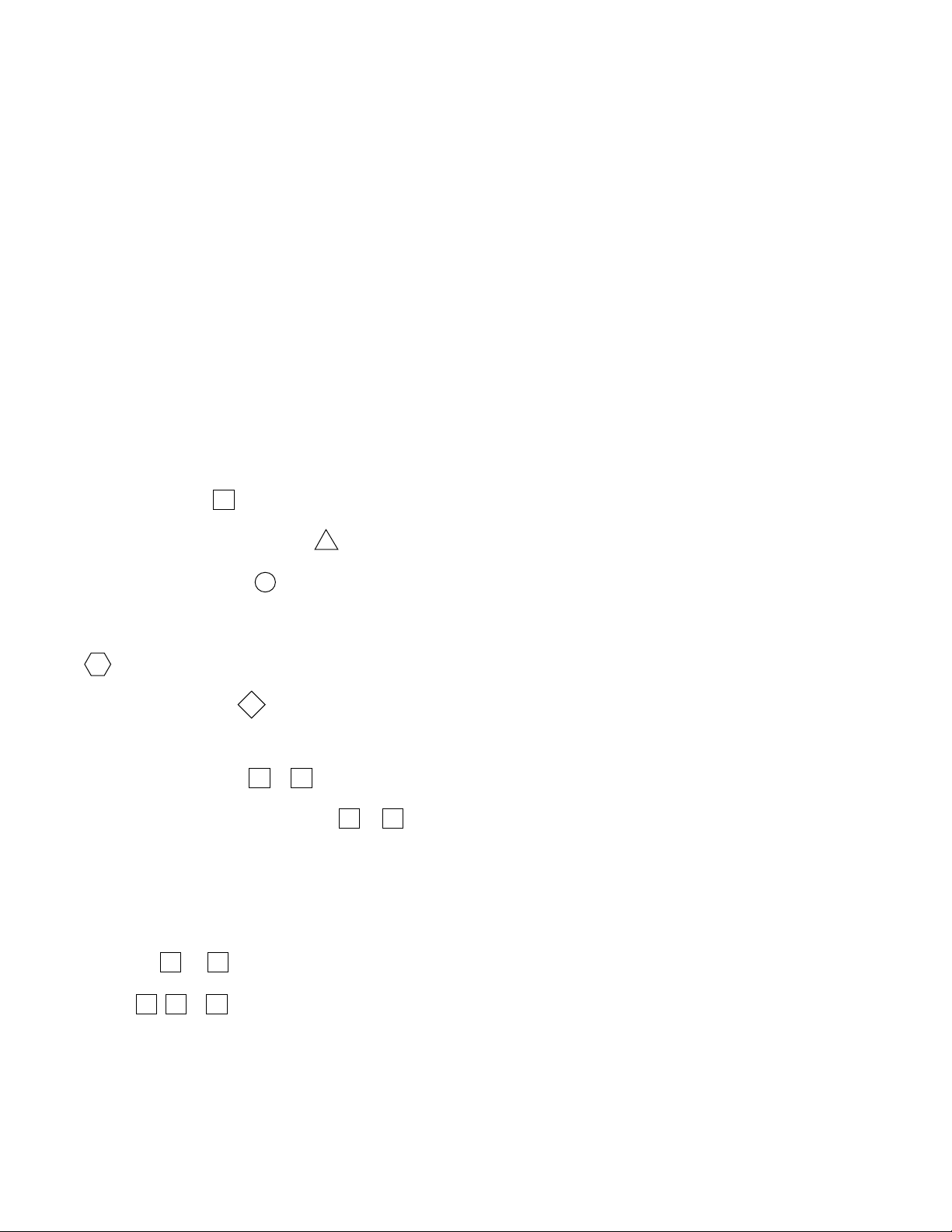

NOTES

1. This wiring diagram describes the standard elec-

tronic control scheme for use with a steam turbine

drive. For details of eld control modications,

refer to Product Form 160.67-PW2.

2. Field wiring to be in accordance with the National

Electrical Code as well as all applicable codes and

specications. Refer to Form 160.67-PW5 (Top

Mount Steam Condenser) and Form 160.67-PW4

(Floor Mount Steam Condenser) for eld wiring

connections.

3. Numbers along the left side of the diagram are

line identication numbers. The number along

the right side indicates the line number location

of relay contacts. An underlined contact location

signies a normally closed contact.

4. Main Control Panel Class 1 eld wiring terminal

connection points are indicated by numbers with-

in a rectangle i.e. 15 . Main Control Panel factory

wiring terminal connection points are indicated

by numbers within a triangle i.e. 5 . Component

Terminal connection points are indicated by num-

bers within a circle i.e. CI . Numbers adjacent to

circuit lines are the circuit identication numbers.

Power Panel wiring terminal connection points

are indicated by numbers within a hexagon i.e .

L1 . Steam Condenser junction box wiring termi-

nal connection points are indicated by numbers

within a diamond i.e. 80 .

5. To cycle unit ON and OFF automatically and pro-

vide a controlled shutdown. Install a cycling de-

vice between terminals 1 & 13 . (Line 33A) (see

Note 9). If a cycling device is installed, jumper

must be removed between terminals 1 & 13 .

6. Fuse sizes and motor overload setpoints depend

on voltage of single point power supply. See chart

on eld connection diagram on door of panel.

7. To stop unit and not permit it to start again, after a

controlled shutdown install a stop device between

terminals 1 & 8 (Line 32A) (see Note 9). A

remote start-stop switch may be connected to ter-

minals 1 , 7 ,& 8 . (Line 32A) (see Note 9). Re-

mote switches are operative only in the "remote"

operating mode.

8. Contact rating is 5 amps resistive at 120 volts AC

or 240 volts AC.

9. Device contact rating to be 5 milliamperes at 115

volts AC.

10. Three phase power must be properly phased. L1,

L2, & L3 corresponding to phase sequence A, B,

& C.

11. Contact rating is 5 Amps resistive at 250 volts AC

& 30 volts DC 2 Amp inductive (.4 PF) at 250

volts AC & 30 volts DC.

12. Each 115 VAC eld-connected inductive load

I.E. relay coil, motor starter coil, etc. shall have a

transient suppressor wired in parallel with its coil,

physically located at the coil. Spare transient sup-

pressor and control circuit fuses are supplied in

a bag attached to the green ground screw in the

lower left corner of the control panel.

13. Turbine auxiliary oil pump, oil cooler, oil sensors

& turbine oil safety logic are supplied only on

turbines with pressurized lubrication.

14. If optional chilled and condenser liquid low pres-

sure dierential switches are installed, panel must

be congured for "digital" ow sensor. Refer to

Form 160.67-O1.

15. Refer to Operators Manual for a detailed descrip-

tion of chiller operation & all wanring/shutdown

operating points.

16. Do NOT apply voltage on eld wiring terminal

blocks TB4 or TB6. All 115 volt AC power is fed

from terminals 1 & 2.

17. Do NOT apply voltage on eld instrument wiring

terminal block TB7. All instrument loop power is

supplied from terminals 325, 327, & 329 .

18. YST chillers are supplied with automatic starting

as standard. Manual starting is not recommended

and will be supplied by special quote only.

19. Manual motor protector auxiliary contact is open

when operator is in the OFF position, closed when

operator is in the ON or any tripped position.

20. Liquid injection solenoid is supplied on K3, K4,

& K7 compressors only.

21. Optional wiring between the chiller terminal box

and the oor mounted steam condensor is sup-

plied by the factory for installation in conduit by

the electrical installation contractor.

22. For standard top mounted steam condensor cables

28, 30, and 42 are connected directly to devices

shown after the steam condensor is installed in the

eld.