■EPDT-079d■

8.

Maintenance Procedure

8.1 Warning and Caution for Maintenance

Warning

(1) Do not touch the trap directly with bare hands.

※Doing so may result in burns.

(2) Trap shall be disassembled and inspected by qualified person or manufacture.

※Request the maintenance to specialized dealer or manufacture in case of any problems.

(3) Remove all internal pressure of the product, piping, and equipment before disassembly and inspection. And

cool down the product.

※Residual pressure in the product or piping can result in burns.

Caution

(1) Inspect a product daily.

※ It is needed to maintain the original performance.

(2) In case of no operation for a long period, perform operating examination before start operation again.

※ Failure to do so may malfunction by rust in the products and piping.

(3) Put a container under the products at disassembly since condensate may flow out.

※ In case of no container for condensate, it makes dirty surrounding of the trap.

(4) Take care not to fall parts down during the disassembly. Use soft cloth; put disassembled parts on it not to

make scratches them.

※Failure to do so, original performance may be affected.

(5) Secure tight assembly of all parts.

※Failure to do so may malfunction or leakage to outside.

(6) When repair the product, proper parts must be used. And do not alter product.

※Using the improper parts and alternation of the product may be result on injury or burns by breakage of

product, blowing out of steam or condensate, or malfunction.

(7) Replace gaskets with new ones when reassembling.

※The gasket is consumable parts. Reuse of gaskets may cause steam leakage problem.

(8) With leakage problem such as continuous blowing out of condensate by existence foreign matters

between valve and valve seat, contact us or our agent since disassemble, repair or replace of parts may be

needed.

(This leakage problem by the customer using is not under our warranty.)

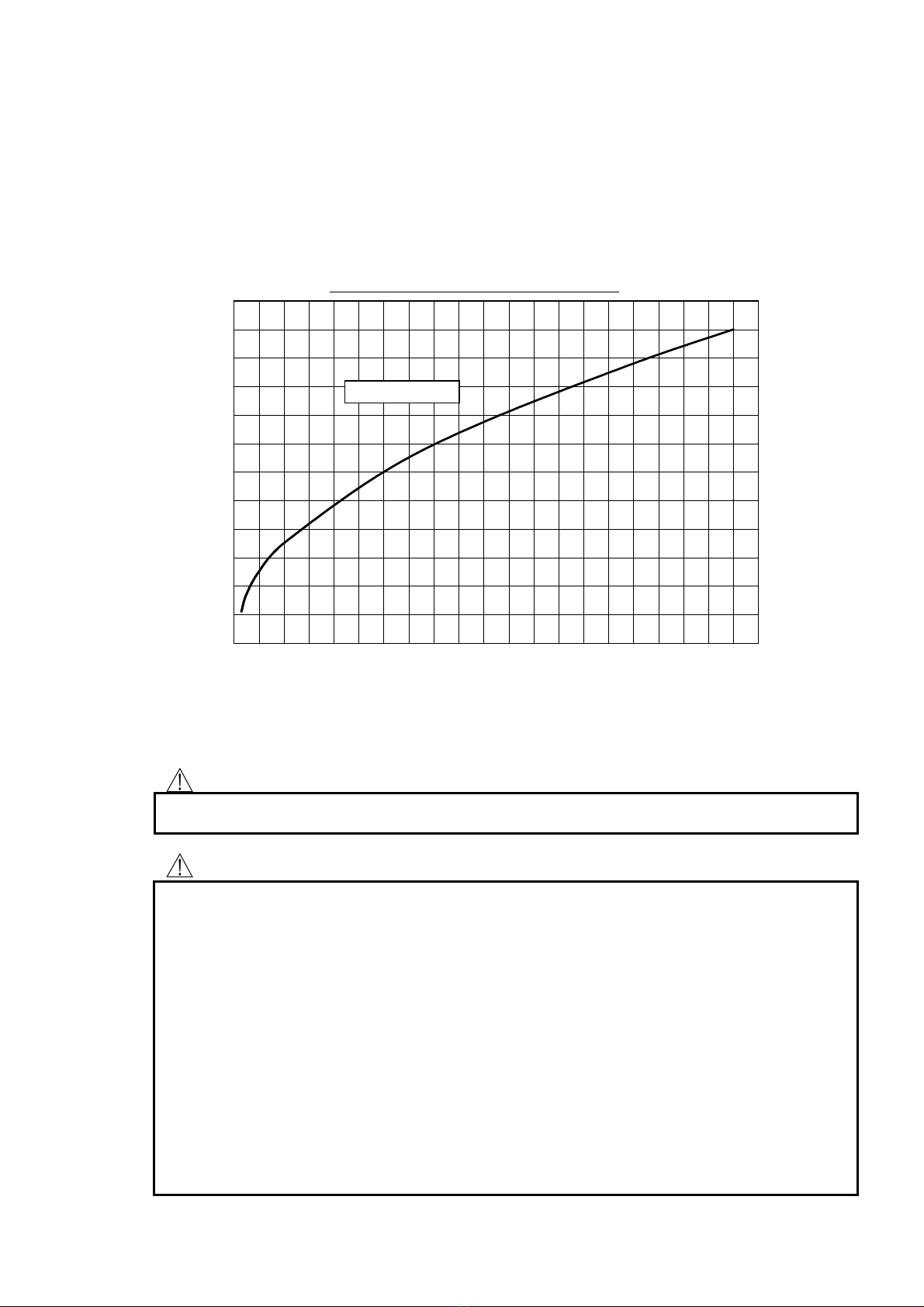

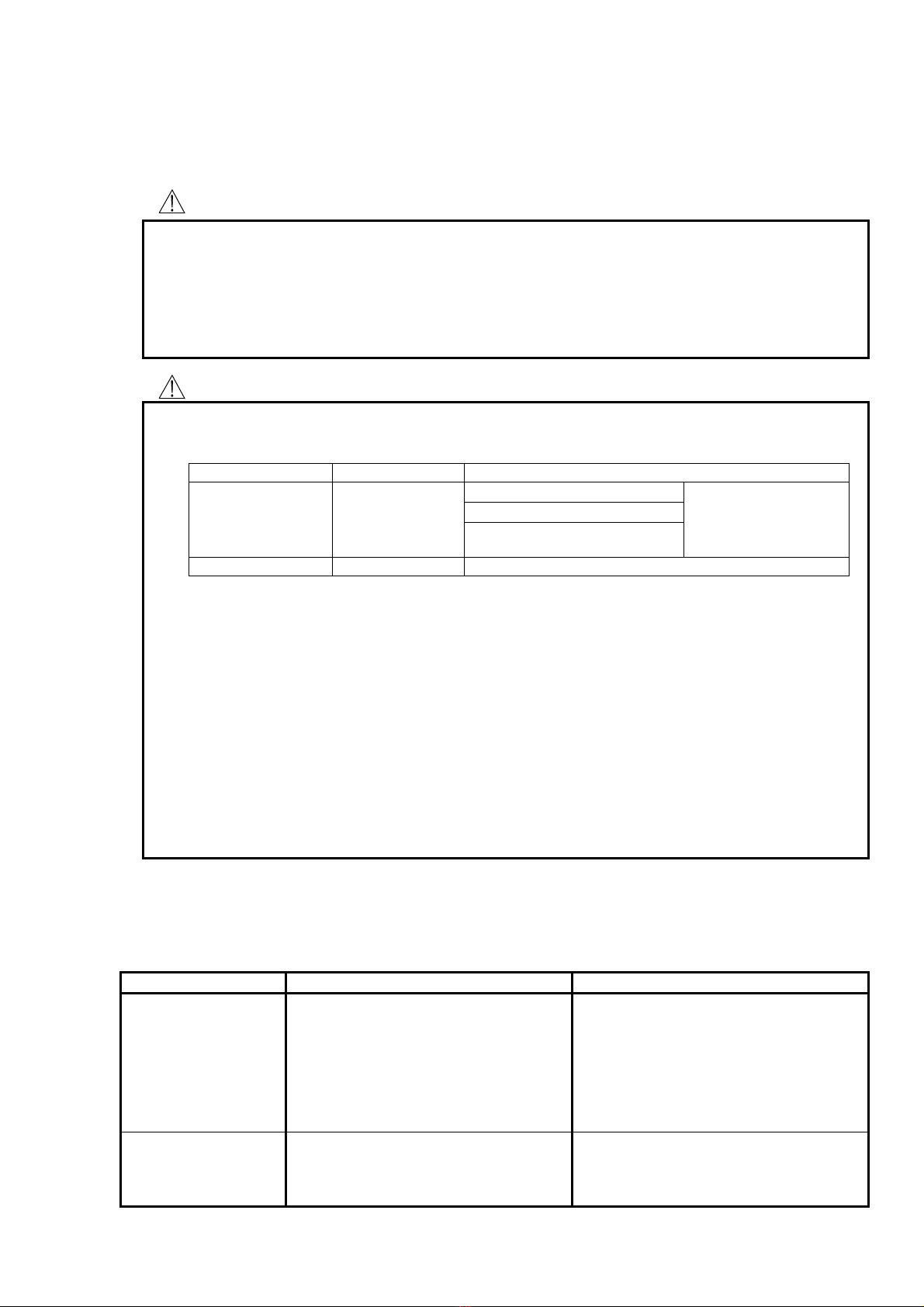

8.2 Troubleshooting

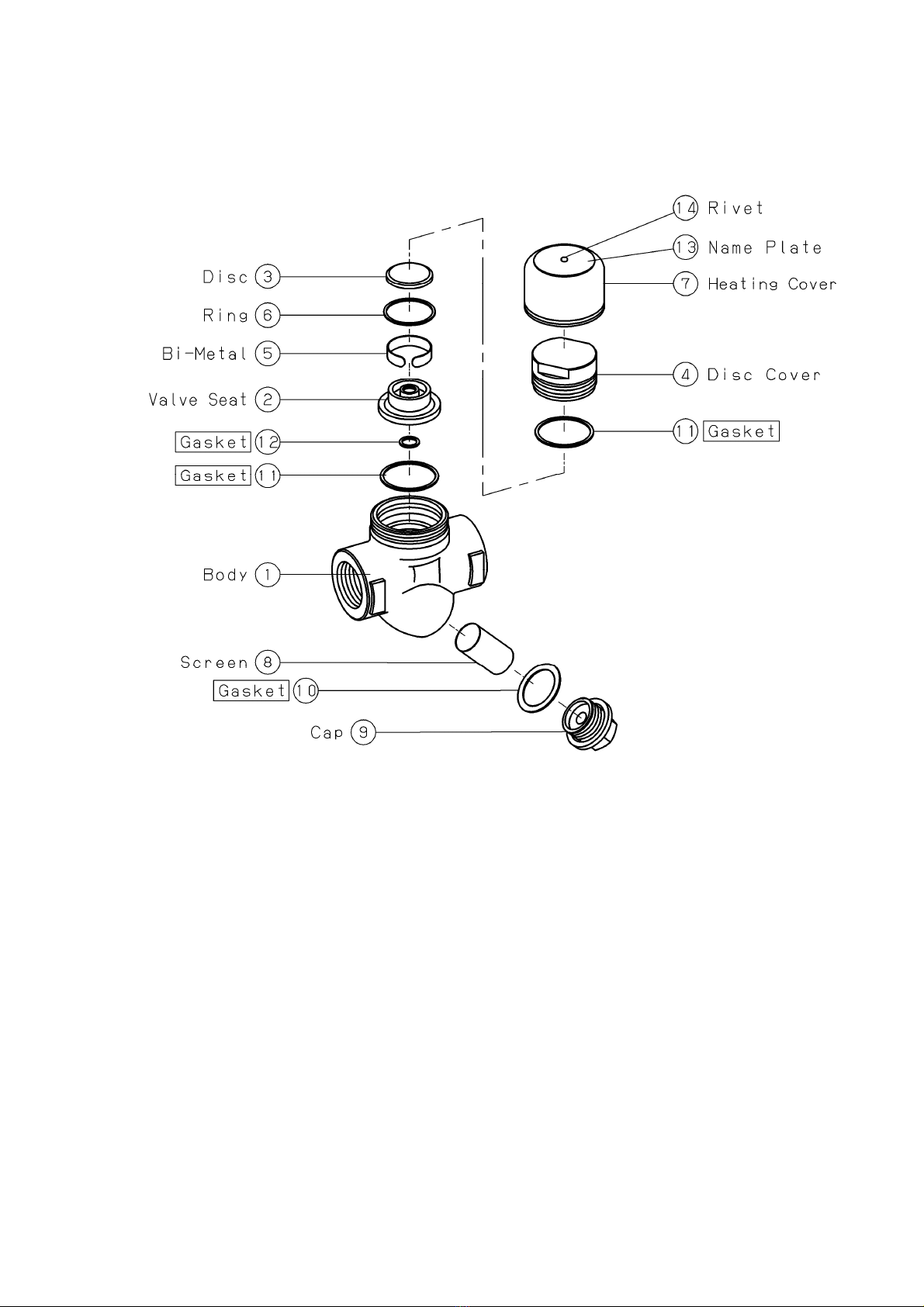

Problem Cause Solution

Condensate is not

Discharged. 1. Blockage in a discharge hole of valve

seat②. 1. Disassemble and clean it.

2. Screen⑧is clogging. 2. Disassemble and clean it.

3. Breakage as a result of abnormal

pressure rising such as freezing or

water hammer.

3. Replace the trap.

Improper discharge. 1. Operating differential pressure of the

trap is not high enough. 1. Examine the inlet/outlet pressure o

trap.

2. The screen⑧is clogging. 2. Disassemble and clean it.

Daily inspection

Item Inspecting way Troubleshooting

Discharge of

condensate

Visual inspection

(1)No condensate discharge

Refer to 8.2

Troubleshooting.

(2) Poor condensate discharge

(3)

Continuous discharge

of

condensate or steam.

Leakage to outside Visual inspection

Refer to 8.2 Troubleshooting.