7

StairMax 600

Stabilisation guide

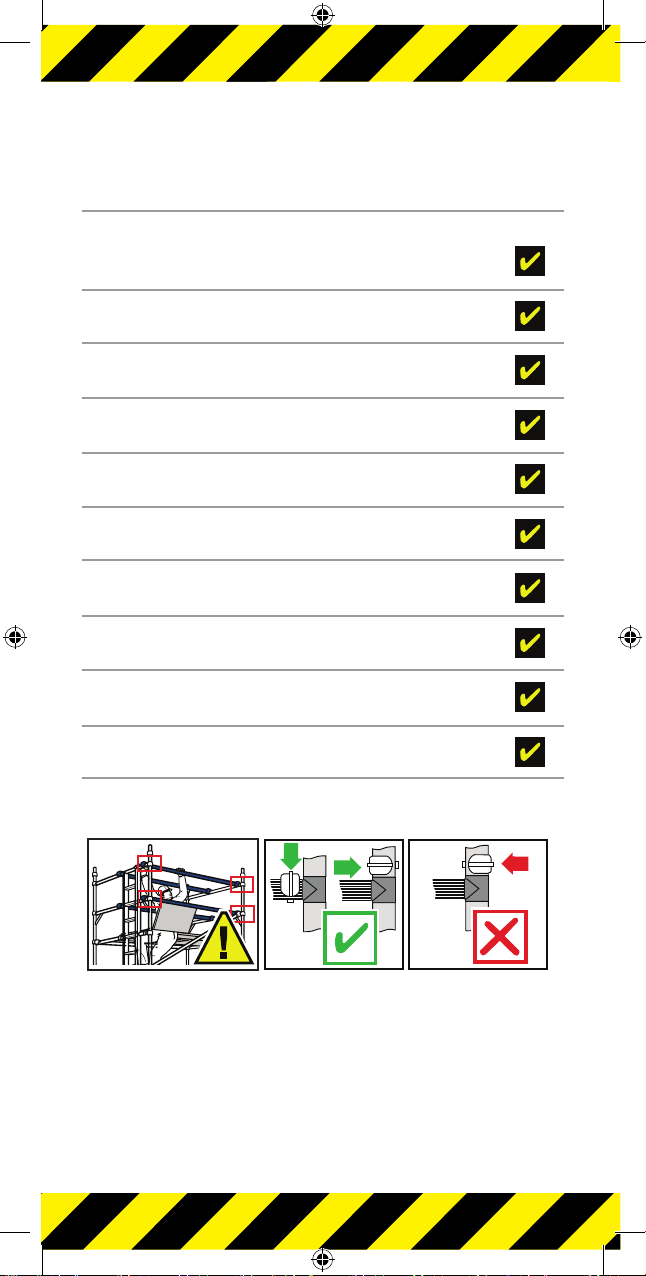

Refer to the table below for the correct method(s) of

stabilising the tower for the stairwell in which you intend to

erect it:

Position of tower in

Stairwell

Staircase clear Width

0.8 to

1.4m

1.4 to

2.0m

2.0m or

greater

Free standing (No walls on

either side of staircase) A A A or C

Up against a wall on one

side of the staircase A or D A, B or D A, B or D

Mid-way between walls

on each side of staircase A or D A or D A or C

For additional stability more than one stabilisation method

may be used. The manufacturer strongly recomends

that ballast be used in all applications in addition to the

alternative methods indicated by this guide.

Methods of stabilisation:

AStrongly recomended: The tower is fitted with 150kg of

ballast uniformly spread along the bottom rung of

each base frame (i.e. 75kg at each end). Please contact

your supplier or hire shop for details.

BThe tower is positioned up against a wall on one side,

and a stabiliser is fitted on the other, to the end frame

on the lower step. The stabiliser must have a minimum

sideways extension of 650mm, and reach down the stairs

for a minimum distance of 650mm.

CThe tower is fitted with a stabiliser on both sides, each

with a minimum sideways extension of 650mm, and

reaching down the stairs for a minimum distance of

650mm. Additional stabiliser available from your supplier or

hire shop.

DThe tower is fixed solidly to a wall on one side with ties.

They should be rigid , two-way ties fastened to both

uprights of the frame with load bearing right angled or

swivel couplers. Only couplers suitable for the 50.8mm

diameter tube of the tower should be used. Ideally ties

should secure to either the face of a solid structure or by

means of anchorages. Tying in with rope or non rigid

members is not acceptable.