YSI 5X00

5

YSI 5X00

4

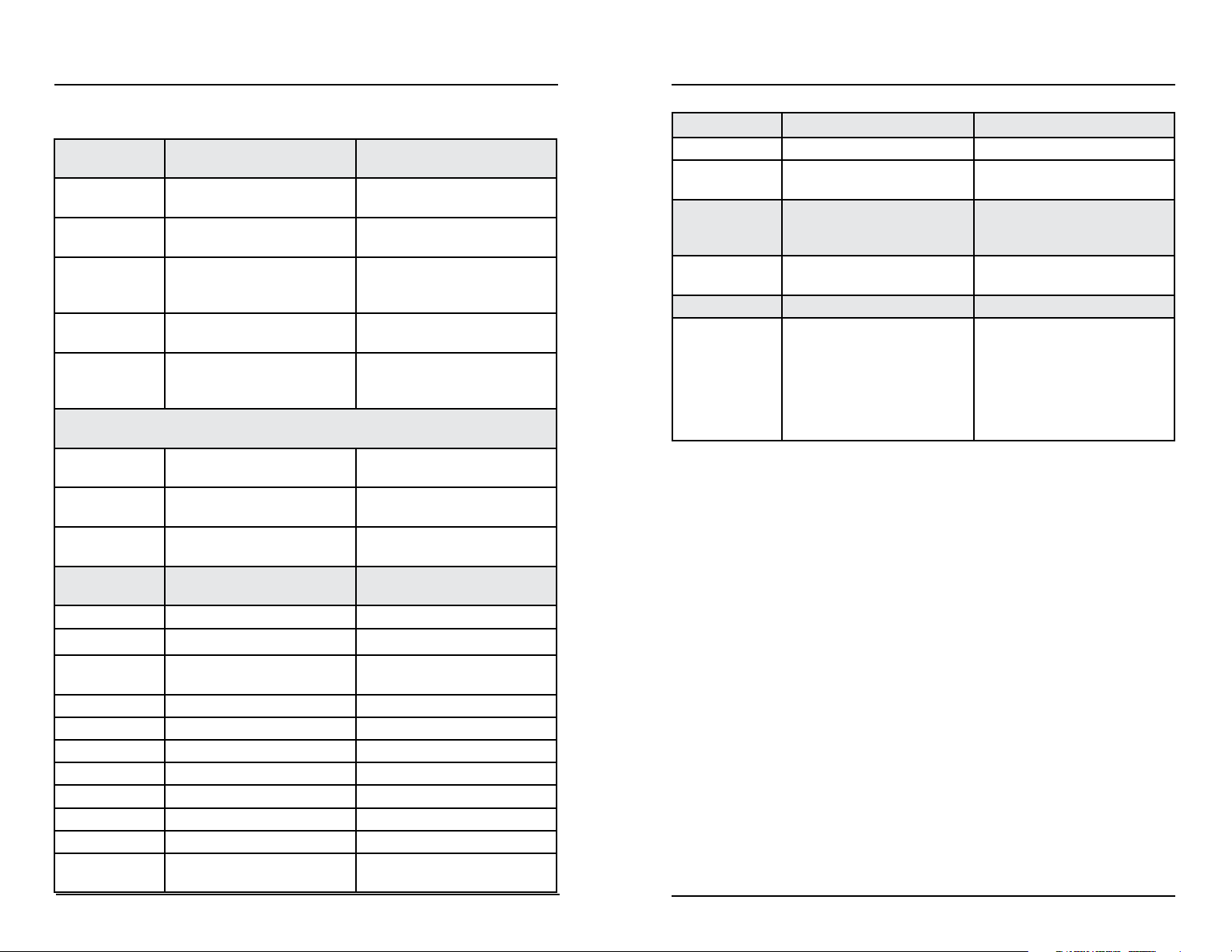

Table of Contents

Directions to Wire AC Power ..............................................45

Wire DC Power and Backup Power .........................................46

Directions to Wire DC Power/DC Backup Power ...............47

Step 5 Wire Sensor(s)....................................................................49

Wire DO Sensors .....................................................................49

Directions to Wire DO Sensor(s) ........................................49

Wire Temperature Sensor(s) ....................................................52

Directions to Wire Temperature Sensor(s) .........................53

Step 6 Wire Relay outputs .............................................................54

Directions to Wire Relay Outputs .............................................54

Wiring a Contactor ...................................................................55

Step 7 Wire Aux Inputs (Non Temperature) ...................................56

Directions to Wire Aux Inputs (Non Temperature Inputs) .........57

Step 8 Wire Network ......................................................................60

Directions to Wire Network.......................................................61

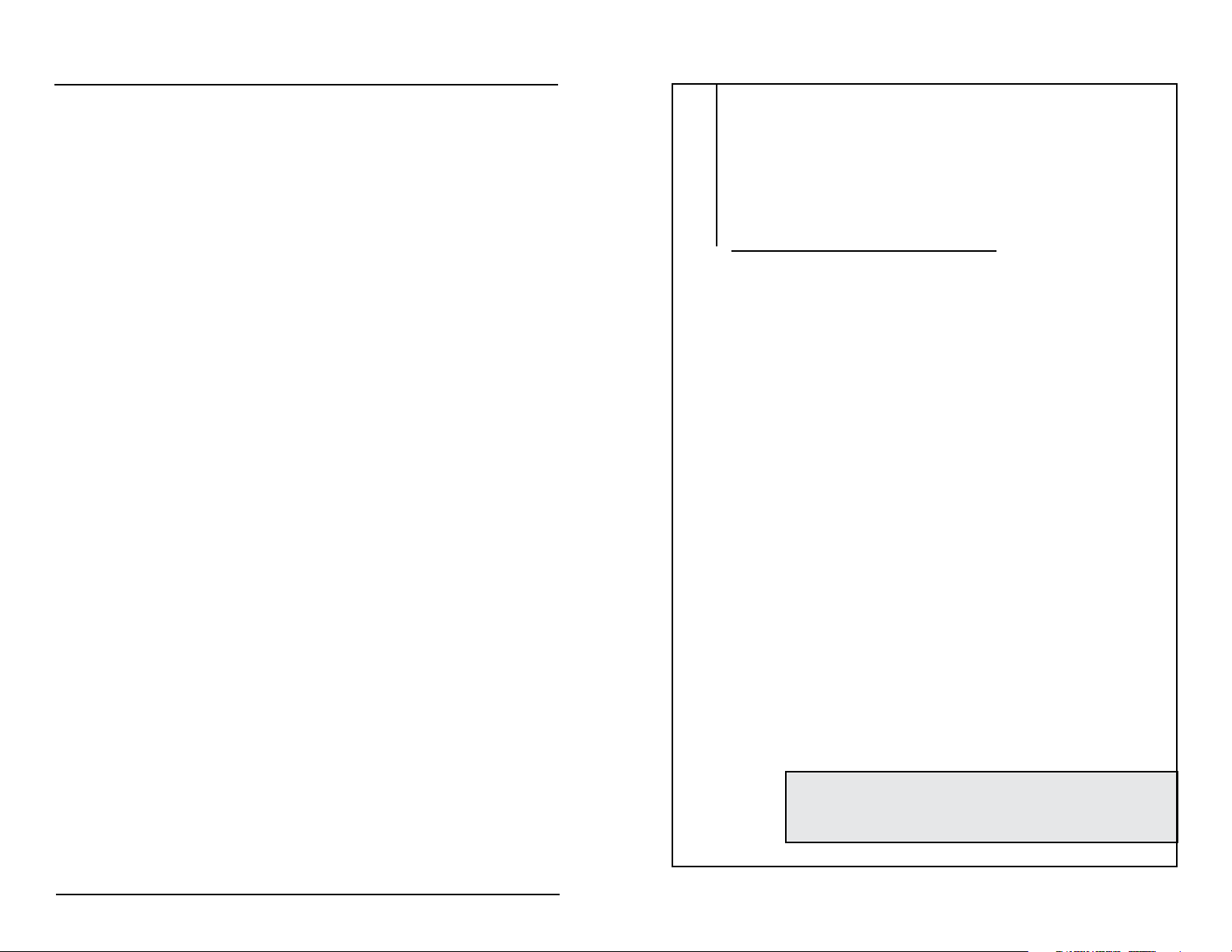

Step 9 Wire and Install Communication Equipment.......................66

Email Alarming .........................................................................66

RS232 Communication ............................................................66

Ethernet (TCP/IP) Module Communication..............................68

Step 10 Install and Wire IOEM/REM instruments ..........................68

Lightning and Surge Protection......................................................68

Sealants, Desiccants, and Securing 5X00.....................................69

4 Conguring 5X00 Systems ................................... 71

5X00 Conguration and Monitoring .....................................................72

Front Panel Keys ...........................................................................73

Softkeys ...................................................................................73

Run Screen ....................................................................................75

Run Screen Icons.....................................................................76

Menus ............................................................................................78

Submenu Screen Types...........................................................80

Main Menu .....................................................................................81

Calibration Menu............................................................................81

Getting Ready to Calibrate.......................................................82

Calibration Log .........................................................................83

DO............................................................................................83

Directions to Calibrate DO Sensor %Sat............................83

Directions to Calibrate DO Sensor mg/L ............................84

Local vs Remote Instruments ........................................................86

System Menu .................................................................................86

Adjust Contrast.........................................................................87

Buzzer ......................................................................................88

BackLighting Timer...................................................................89

Communication ........................................................................89

Email Alarming....................................................................90

Ethernet..............................................................................92

Node Network.....................................................................97

Send Test Email Msg..........................................................99

Email Retry Delay...............................................................100

Force Serial Port.................................................................101

Non-Networked (Stand Alone) 5X00s ......................................101

Congure AUX .........................................................................102

Probe Name .......................................................................102

Input Type...........................................................................103

Congure E-AUX ......................................................................108

Probe Name .......................................................................109

Instrument...........................................................................110

Channel ..............................................................................111

Input Type...........................................................................111

Data Logging............................................................................117

Data Logging ......................................................................118

Event Logging ....................................................................120

Date/Time.................................................................................122

Display Settings .......................................................................123

ODO Cal K (5500D-01, 5500D-02 and 5500D-04)............................ 124

Downloader/Updating 5X00 Firmware .....................................126

Firmware Updater Directions..............................................127

Force Downloader ..............................................................130

General Alarm ..........................................................................131

Alarm Hold Off....................................................................132

Relay ..................................................................................132

Name Devices/Sensors............................................................134

Password .................................................................................137

Power Fail Menu ......................................................................138

Serial Number ..........................................................................139

Service .....................................................................................140

Reset Clean Probes ...........................................................140

Reset To Factory ................................................................141

Output Test .........................................................................144

Service Hold.............................................................................147

Version .....................................................................................148

AquaManager and the System Menu ............................................149

Sensor Setup .................................................................................150

Control Mode............................................................................152

Set Point Control ................................................................153

Timed versus Normal (non timed) Control..........................157

Table of Contents