User Information

H. ZANDER GmbH & Co. KG • Am Gut Wolf 15 • 52070 Aache • Germa y

Tel +49 (0)241 9105010 • Fax +49 (0)241 91050138 • info@zander-aachen.de • www.zander-aachen.de

3

Safety Emergency Stop Relay SR3D

M03

Ver. B

E61-139-00

English translation

Errors and technical changes reserved

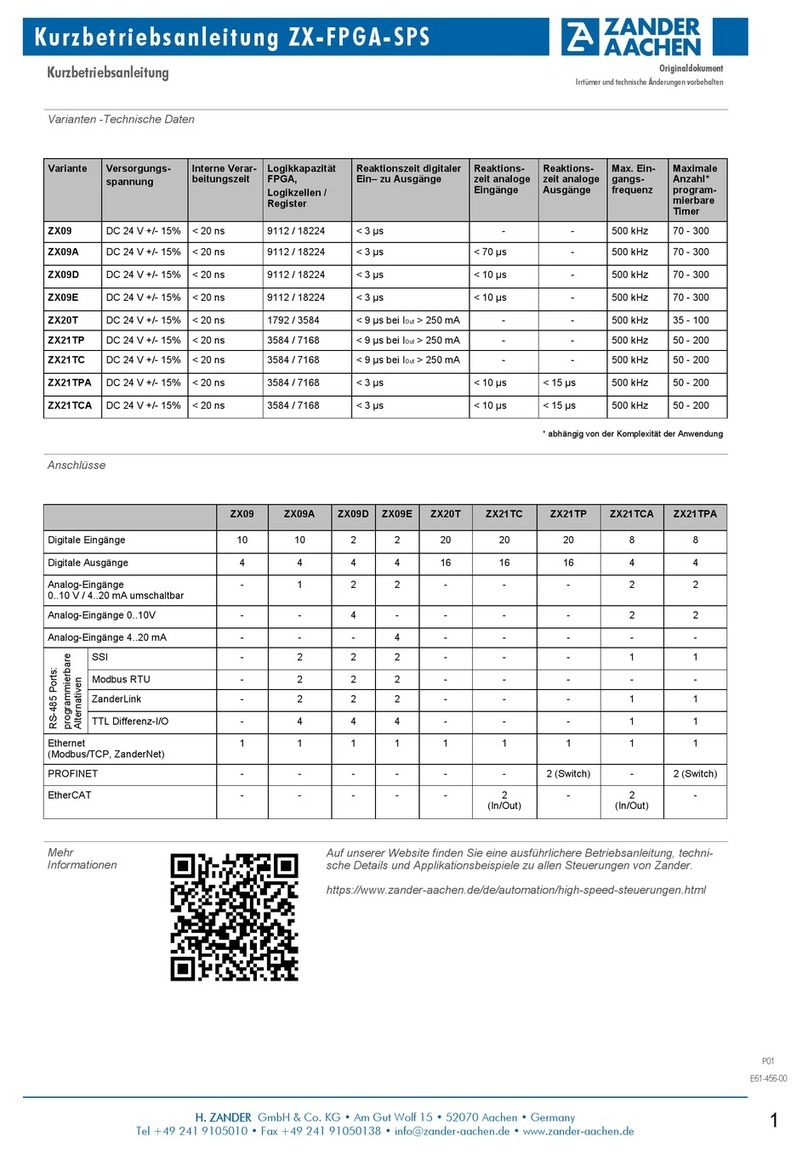

Techn. Data

In compliance with EN 60204-1; DIN EN ISO 13849-1; EN 62061; EN 50156-1;

EN 746-2; IEC 61508 Parts 1-2 and 4-7; IEC 61511-1

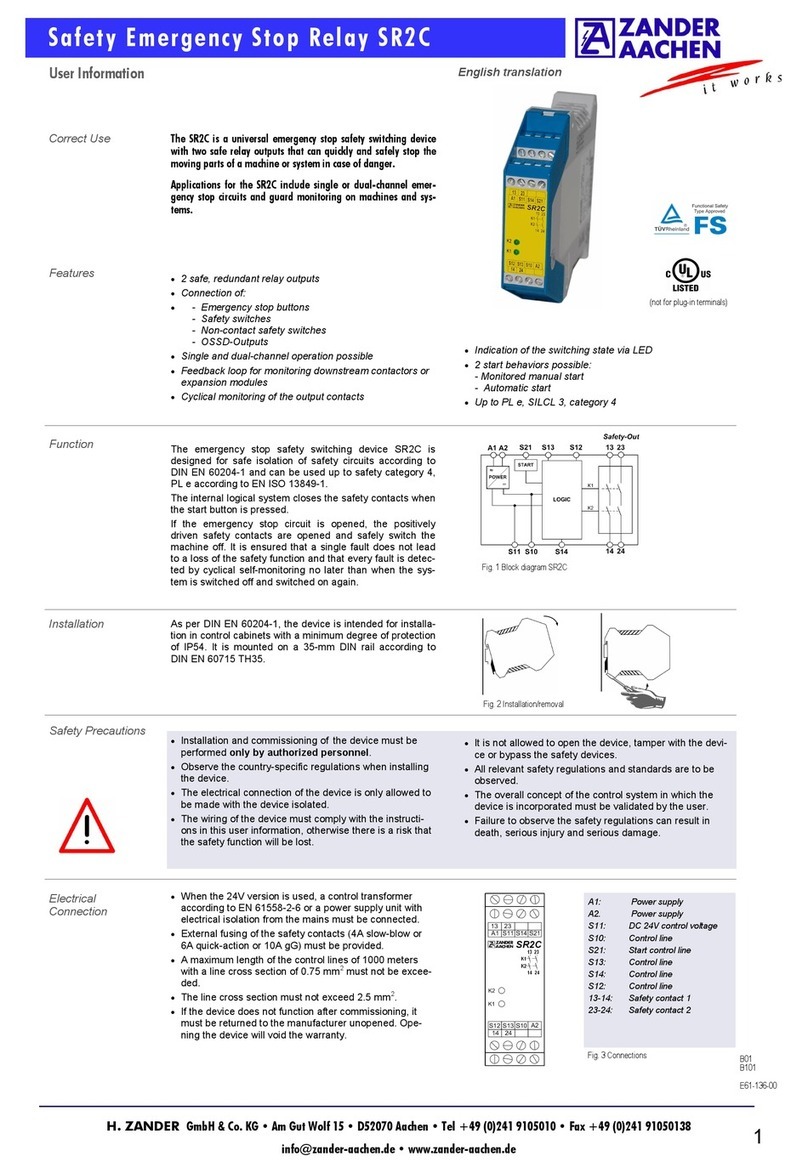

Operating voltage AC 230 V, AC 115 V, AC/DC 24 V

Rated supply frequency 50-60 Hz

Allowable tolerance + / - 10 %

Power consumption DC 24 V AC 230 V

approx. 2 W approx. 6.9 VA

Control voltage at S11 DC 24 V

Control current at S11...S14 max. 100 mA

Safety contacts 3 NO

Auxiliary contacts 1 NC

Switching voltage max. AC 250 V

Contact rating of safety contacts (13-14, 23-24, 33-34) *) AC: 250 V, 2000 VA, 8 A for resistive load

6 switching cycles/ min

250 V, 3 A for AC-15

DC: 30 V, 240 W, 8 A for resistive load

24 V, 3 A for DC-13

UL: C300 / R300

Cumulative current Max. 15 A (13-14, 23-24, 33-34)

Contact rating of auxiliary contact (41-42) AC: 250 V, 500 VA, 2 A for resistive load

DC: 30 V, 60 W, 2 A for resistive load

Minimum voltage/current 5 V, 10 mA

External fuses for safety contacts 10 A gG

6 A gG for applications acc. to EN 50156-1

(See Chapter 10.5.5.3.4)

Wire width 0.14 - 2.5 mm2

Tightening moment (Min. / Max.) 0.5 Nm / 0.6 Nm

Typ. switch-on delay / switch-off delay < 30 ms / < 20 ms

Length of control lines Max. 1000 m at 0.75 mm2

Contact material AgSnO2

Service Life mech. approx. 1 x 107

Rated impulse withstand voltage 2.5 kV (control voltage / contacts)

Dielectric strength 4 kV (DIN VDE 0110-1)

Rated insulation voltage 250 V

Protection IP20

Temperature range DC 24 V: -15 °C bis +55 °C

AC 115 V / 230 V: -15 °C bis +55 °C

(see load curve)

Max. altitude ≤2000 m (above sea level)

Degree of pollution / Overvoltage category 2 / 3 (DIN VDE 0110-1)

Weight approx. 230 g

Mounting DIN rail according to EN 60715 TH35

*) If several SR3D-24V are mounted closely together the maximum cumulative current is 9A at an ambient temperature of

20°C or 3 A at 30 °C or 1 A at 40 °C. If the current exceeds these limits, keep a minimum space of 5 mm between the

devices.

5. Starting the device:

Switch on the operating voltage.

Warning:

If the “Automatic start” starting behavior is set, the safety

contacts will close immediately.

If the “Monitored manual start” starting behavior is set,

close the start button to close the safety contacts.

LEDs K1 and K2 are lit.

6. Triggering safety function:

Open the emergency stop circuit by actuating the connec-

ted safety switch. The safety contacts open immediately.

7. Reactivation:

Switch the device on again as described under 5.

Device cannot be switched on again after an emergency

stop:

•

Emergency stop circuit was closed again.

•

Was the start button opened before closing of the emer-

gency stop circuit (manual start)?

•

Is the feedback loop closed?

If the fault still exists, perform the steps listed under

“Commissioning Procedure”. If these steps do not remedy

Device does not switch on:

•

Check the wiring by comparing it to the wiring diagrams.

•

Check the safety switch used for correct function and

adjustment.

•

Check whether the emergency stop circuit is closed.

•

Check whether the start button (manual start) is closed.

•

Check the operating voltage at A1 and A2.

•

Is the feedback loop closed?

What to do in

Case of a Fault?

Caution: Opening the device is impermissible and will void the warranty.

Check and Mainte-

nance

The following checks are regularly required to ensure

proper and continuous functioning:

•

Check the switch function

•

Check for signs of manipulation and safety function

bypassing

•

Check if the device is mounted and connected securely

•

Ceck for soiling

Check if the safety device is working properly, in particular:

•

Every time after initial commissioning

•

Every time after replacing a component

•

After every fault in the safety circuit

Regardless of this, the safe functioning of the safety device should be checked at suitable intervals, e.g. as part of the mainte-

nance schedule of the plant. No maintenance is required for the device itself