User Manual

1

Safety Coupling Relay SR7D

M03

Ver. A

E61-358-00

H. ZANDER GmbH & Co. KG • Am Gut Wolf 15 • 52070 Aache • Germa y

Tel +49 241 9105010 • Fax +49 241 91050138 • info@zander-aachen.de • www.zander-aachen.de

Safety

Precautions

•

Cyclical monitoring of the output contacts

•

LED indicators for power and status channel 1 and 2

•

2 start modes:

- monitored manual start

- automatic start

•

Short-circuit monitoring and earth fault monitoring

•

Up to PL e, SILCL 3, category 4

•

Stop category: 0

Correct Use SR7D is a safety coupling relay/safety switchgear with seven safe

relay contacts for fast and safe shutdown of hazardous plant

components in the event of danger. t can be used in particular

for furnaces and thermal process plants.

The device can be operated as a coupling relay for connection to

safe semiconductor outputs (e.g. output of a safety PLC). Due to

the integrated self-monitoring, no feedback loop is required for

error monitoring.

The SR7D is specially designed and certified for the use on

furnaces and thermal process plants in continuous operation

according to EN 50156-1 and EN 746-2.

•

7 safety contacts

•

4 auxiliary contacts (relay); 2 solid-state auxiliary outputs

•

Connection of sensors for:

•

- temperature

- pressure

- volume flow

•

Control: single or dual channel

•

Can be used as emergency stop relay with separate

safety circuit

•

Feedback loop for external contactors or extension

modules

Function

The emergency stop safety switching device SR7D is

designed for safe isolation of safety circuits according to

EN 60204-1 and can be used up to SIL 3 according to IEC

61508 and safety category 4, PL e according to EN ISO

13849-1.

When the control signal is switched on or off, the safety

contacts are closed or opened by the internal logic of the

SR7D. The SR7D can also be used as a classic emer-

gency-stop relay by appropriate wiring. In this case, the

safety contacts are closed by closing the emergency stop

circuit and a proper start command. Opening the emer-

gency stop circuit immediately opens the safety contacts.

It is ensured that a single fault does not lead to a loss of

the safety function and that every fault is detected by cycli-

cal self-monitoring no later than when the system is

Installation

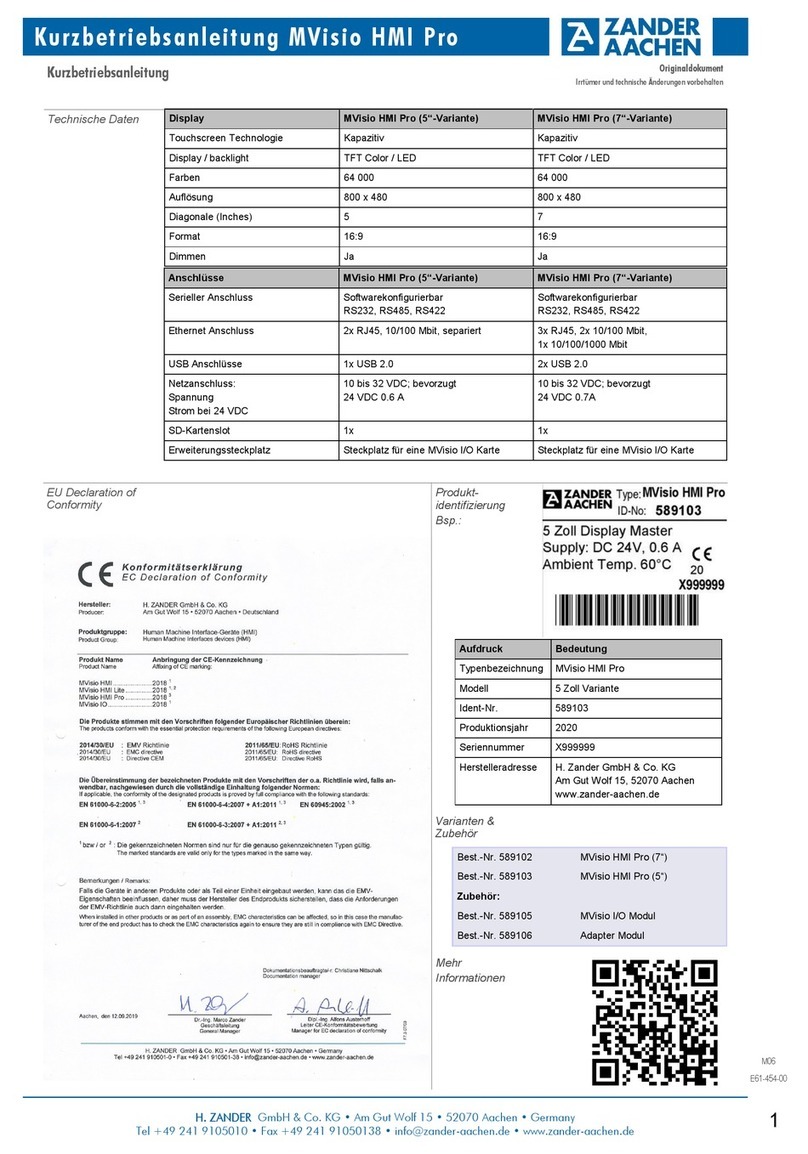

As per EN 60204-1, the device is intended for installation in

control cabinets with a minimum degree of protection of

IP54. It is mounted on a 35 mm mounting rail according to

EN 60715 TH35.

The load curves (see page 4) specify the maximum permis-

sible total thermal current as a function of the ambient

temperature.

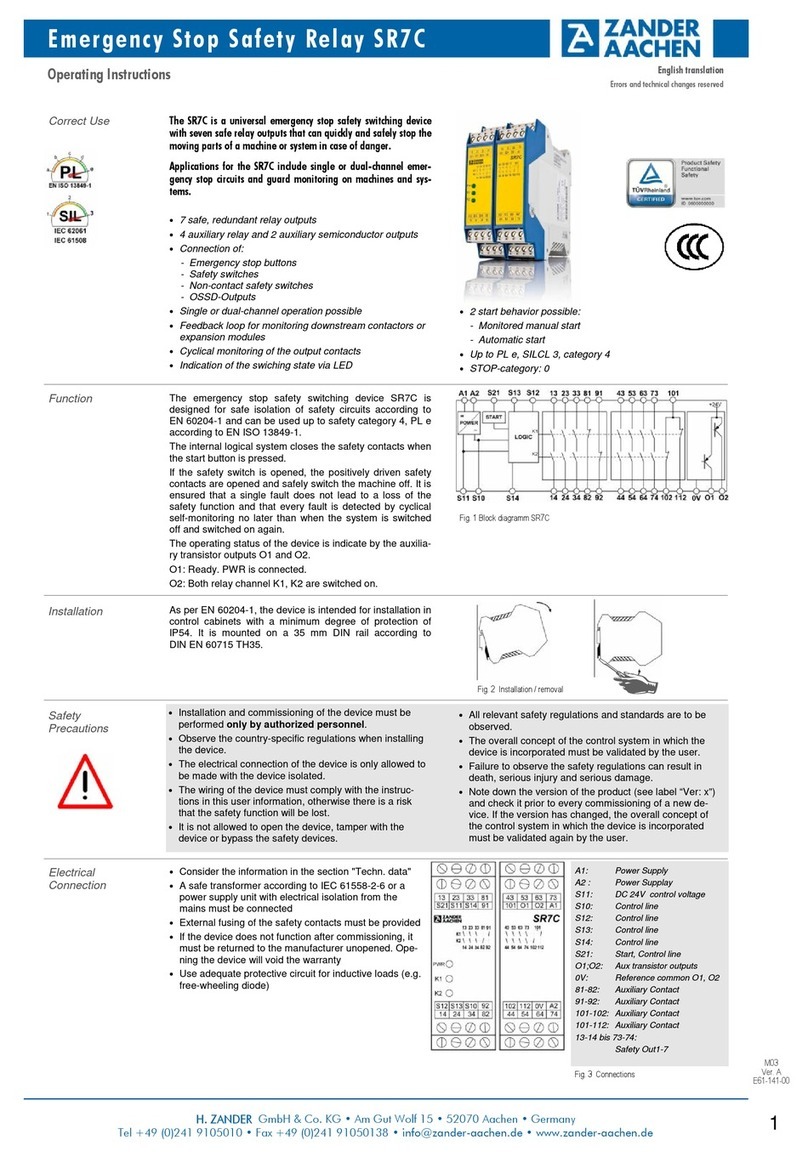

Fig. 2 Mounting / Demounting

Electrical

Connection

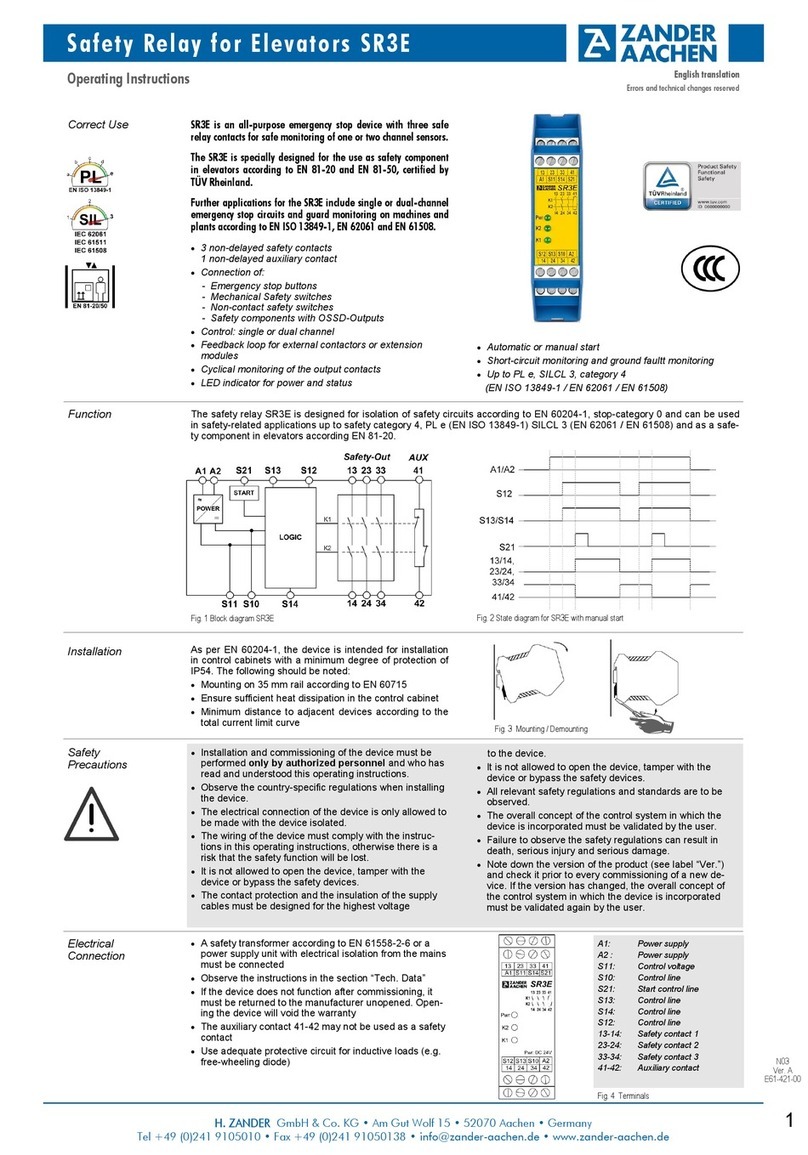

•

A safety transformer according to EN 61558-2-6 or a

power supply unit with electrical isolation from the mains

must be connected

•

Observe the instructions in the section “Tech. Data”

•

Use adequate protective circuit for inductive loads (e.g.

free-wheeling diode)

•

If the device does not function after commissioning, it

must be returned to the manufacturer unopened. Open-

ing the device will void the warranty

•

The auxiliary outputs 81-82, 91-92, 101-102, 101-112

and O1, O2 may not be used as safety contacts

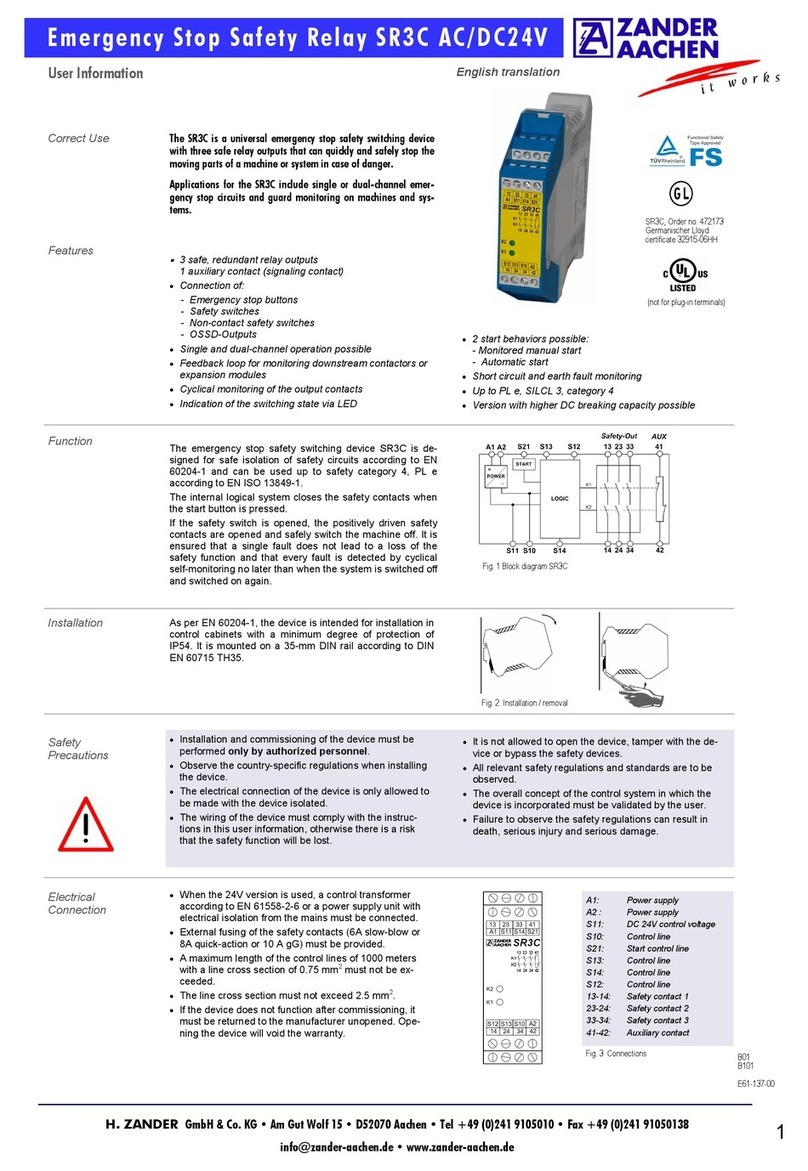

Fig. 3 Terminals

•

It is not allowed to open the device, tamper with the de-

vice or bypass the safety devices.

•

All relevant safety regulations and standards are to be

observed.

•

The overall concept of the control system in which the

device is incorporated must be validated by the user.

•

Failure to observe the safety regulations can result in

death, serious injury and serious damage.

•

Note down the version of the product (see label “Ver.”)

and check it prior to every commissioning of a new de-

vice. If the version has changed, the overall concept of

the control system in which the device is incorporated

must be validated again by the user.

•

Installation and commissioning of the device must be

performed only by authorized personnel and who has

read and understood this operating instructions.

•

Observe the country-specific regulations when installing

the device.

•

The electrical connection of the device is only allowed to

be made with the device isolated.

•

The wiring of the device must comply with the instruc-

tions in this operating instructions, otherwise there is a

risk that the safety function will be lost.

•

The contact protection and the insulation of the supply

cables must be designed for the highest voltage to the

device.

switched off and switched on again. The operating status of

the device is signalled via the semiconductor monitoring

outputs O1 and O2 (reference potential: 0V terminal).

O1: Device ready for operation, PWR (UB) applied.

O2: Both relays K1 and K2 are switched on.

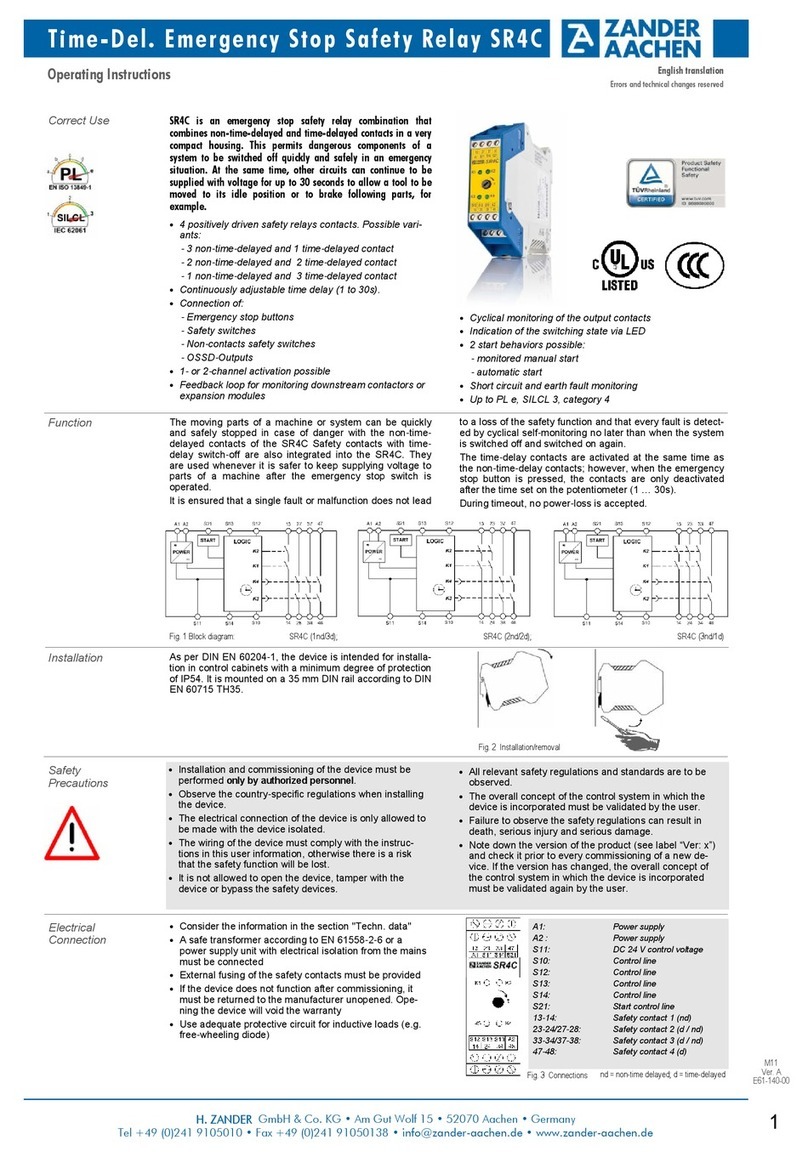

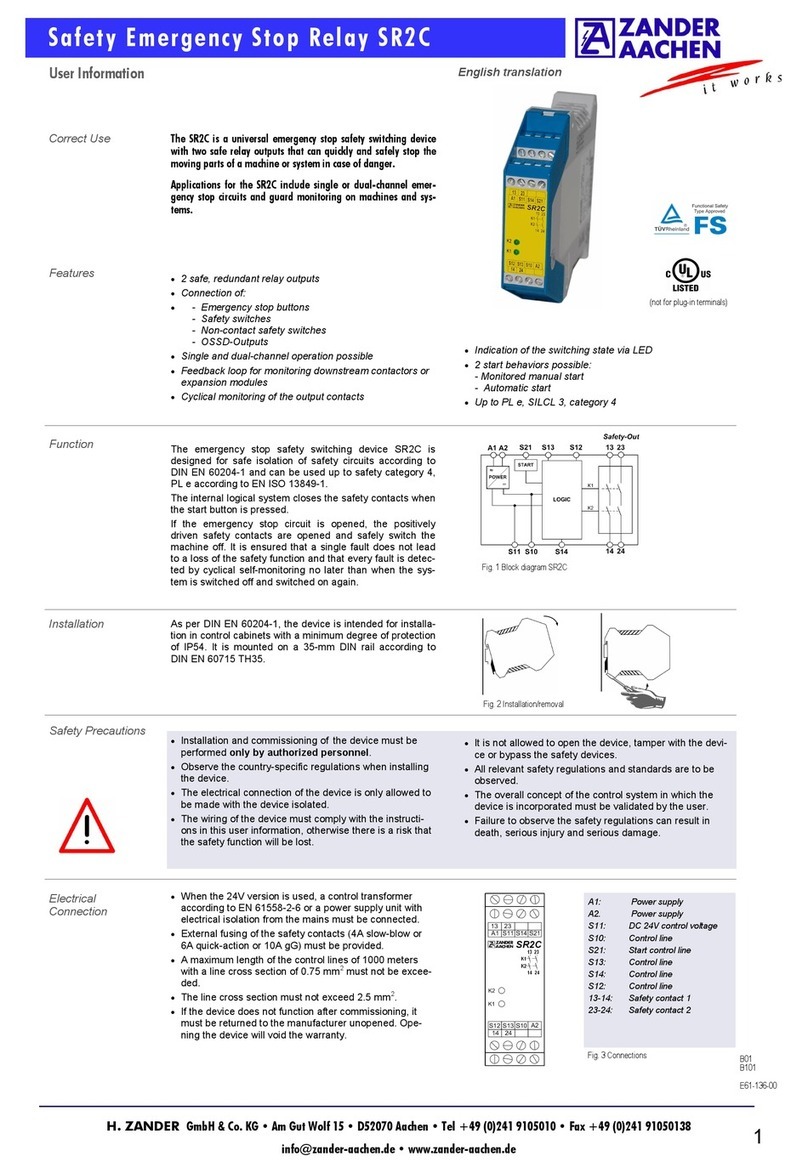

Fig. 1 Blo k diagram SR7D

A1: Power Supply

A2 : Power Supply

S11: DC 24 V control voltage

S10: Control line

S12: Control line

S13: Control line

S14: Control line

S21: Control line Start

O1;O2: Solid-state aux. outputs

0V: Ref. potential O1/O2

81-82: Auxiliary contact

91-92: Auxiliary contact

101-102: Auxiliary contact

101-112: Auxiliary contact

13-14 ..

73-74: Safety contacts 1 to 7

English Translation

Errors and technical changes reserved

Pwr: AC/DC 24V