H. ZANDER GmbH & Co. KG • Am Gut Wolf 15 • 52070 Aache • Germa y

Tel +49 (0)241 9105010 • Fax +49 (0)241 91050138 • info@zander-aachen.de • www.zander-aachen.de

3

Emergency Stop Safety Relay SR7C

M03

Ver. A

E61-141-00

Operating Instructions

English translation

Errors and technical changes reserved

Maintenace

The device must be checked once per month for proper

function and for signs of tampering and bypassing of the

safety function.

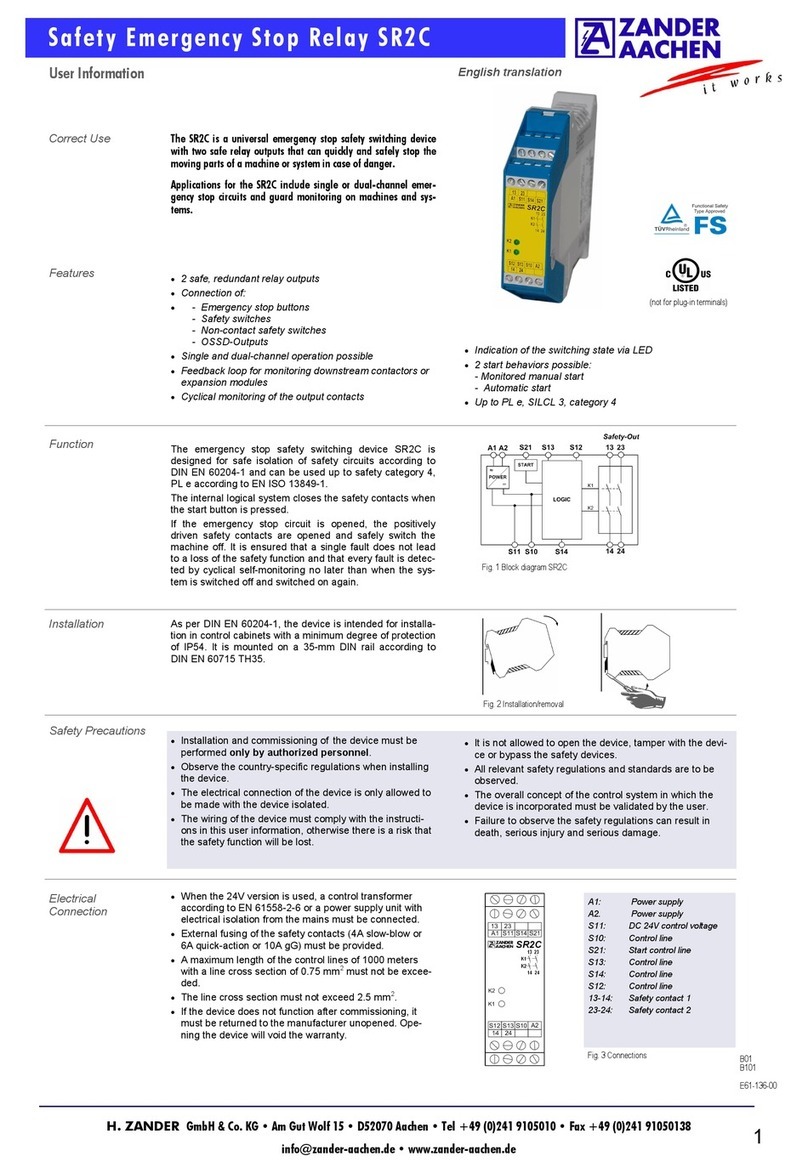

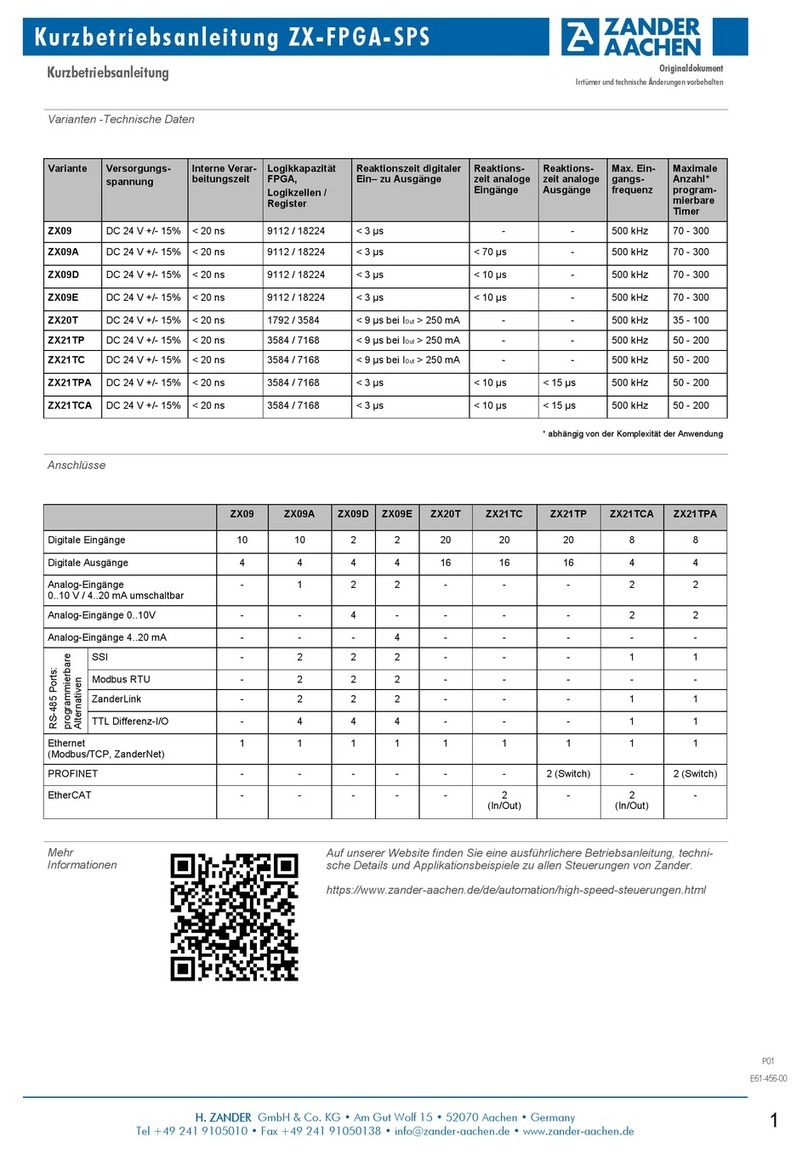

Techn. Data

Corresponds to the standards EN 60204-1; EN ISO 13849-1 ; EN 62061

Operating voltage AC/DC 24 V

Rated Supply Frequency AC: 50-60 Hz

Permissible deviation + / - 10 %

Power consumption DC 24 V AC 24 V

approx. 4.5 W approx. 8.5 VA

Control voltage at S11 DC 24 V

Control current S11..S14 approx. 250 mA

Safety contacts 7 NO contacts

Auxiliary contacts 4 NC contacts

Auxiliary transistor outputs (O1, O2) DC 24 V / 30 mA, over current protected

Max. switching voltage AC 250 V

Safety contact breaking capacity AC: 250 V, 2000 VA, 8 A for ohmic load

(6 switching cycles/ min)

(13-14, 23-24, 33-34,43-44, 53-54, 63-64, 73-74) 250 V, 3 A for AC-15

DC: 40 V, 320 W, 8 A for ohmic load

(6 switching cycles/ min)

24 V, 3 A for DC-13

Max. total current through all 7 contact up to Ta=40 °C:

35 A 10 mm spacing between the devices

20 A no spacing between the devices

Auxiliary contacts braking capacity AC: 250 V, 2000 VA, 8 A for ohmic load

(81-82, 91-92, 101-102,101-112) DC: 40 V, 320 W, 8 A for ohmic load

Minimum contact load 5 V, 10 mA

Min. Contact fuses 10 A gG

Max. line cross section 0.14 - 2.5 mm2

Tightening moment (Min. / Max.) 0.5 Nm / 0.6 Nm

Typ. switch-on delay / switch-off delay for NO contacts < 30 ms / < 20 ms

requested via safety circuit

Max. length of control line 2x 1000 m at 1.5 mm2, 2x 500 m at 0.75 mm2

Contact material AgSnO2

Contact service life mech. approx. 1 x 107

Test voltage 2.5 kV (control voltage / contacts)

Rated impulse withstand voltage, leakage path/air gap 4 kV (DIN VDE 0110-1)

Rated insulation voltage 250 V

Degree of protection IP20

Temperature range -15 °C bis +40 °C

Max. altitude ≤2000 m (above sea level)

Degree of contamination 2 (DIN VDE 0110-1)

Overvoltage category 3 (DIN VDE 0110-1)

Weight approx. 350 g

Mounting DIN rail according to EN 60715 TH35

Note:

Additional data can be requested from the manufacturer for

applications that deviate from these conditions.

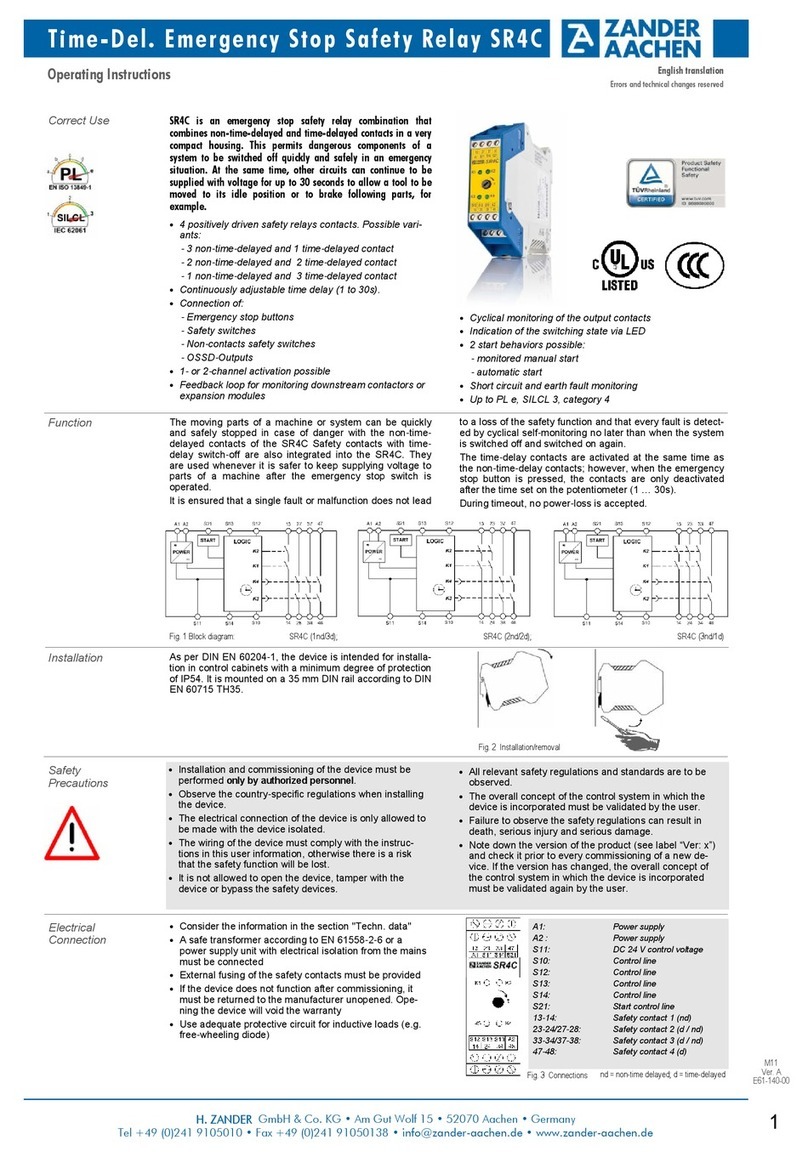

Safety

Characteristics

According to

EN ISO 13849-1

The device is certified according to EN ISO 13849-1 up to a

Performance Level of PL e.

Device cannot be switched on again after an emergency

stop:

•

Check whether the emergency stop circuit was closed

again.

•

Was the start button opened before closing of the emer-

gency stop circuit (with manual start)?

•

Is the feedback loop closed?

If the fault still exists, perform the steps listed under

“Commissioning Procedure”.

If these steps do not remedy the fault either, return the

device to the manufacturer for examination.

Opening the device is impermissible and will void the

warranty.

Device does not switch on:

•

Check the wiring by comparing it to the wiring diagrams.

•

Check the safety switch used for correct function and

adjustment.

•

Check whether the emergency stop circuit is closed.

•

Check whether the start button (with manual start) is

closed.

•

Check the operating voltage at A1 and A2.

•

Is the feedback loop closed?

What to Do in

Case of a Fault?

The device is otherwise maintenance free, provided that it

was installed properly.

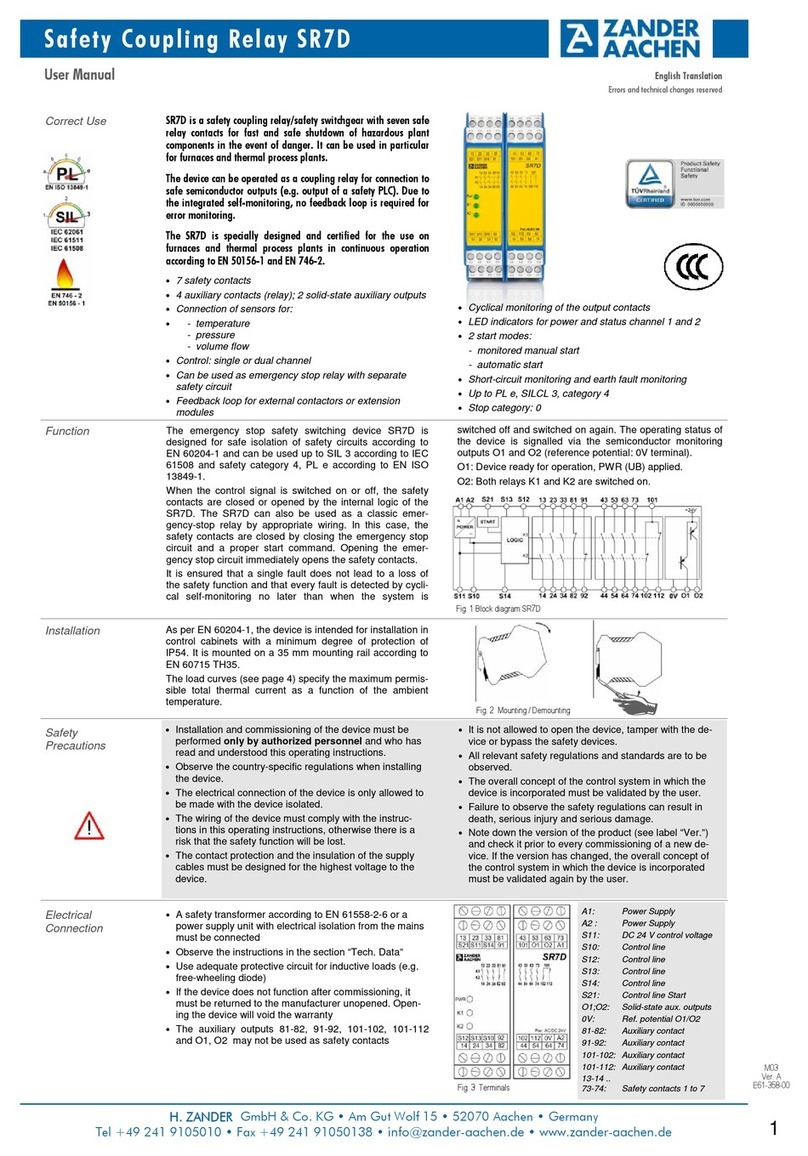

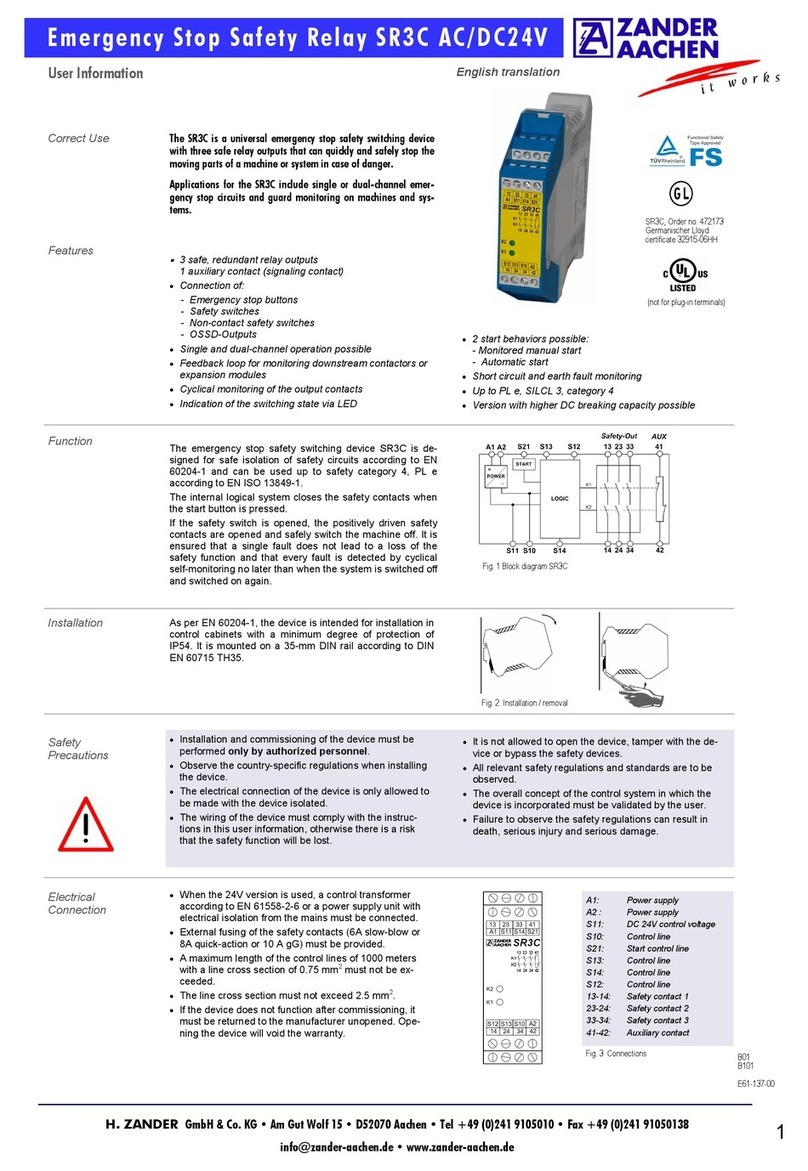

Safety characteristics according to EN ISO 13849-1 for all variants of SR7C

Load (DC-13; 24 V) <= 0,1 A <= 1 A <= 2 A

T10d [years] 20 20 20

Category 4 4 4

PL e e e

PFHd [1/h] 2,47E-08 2,47E-08 2,47E-08

nop [cycle / year] <= 500.000 <= 350.000 <= 100.000