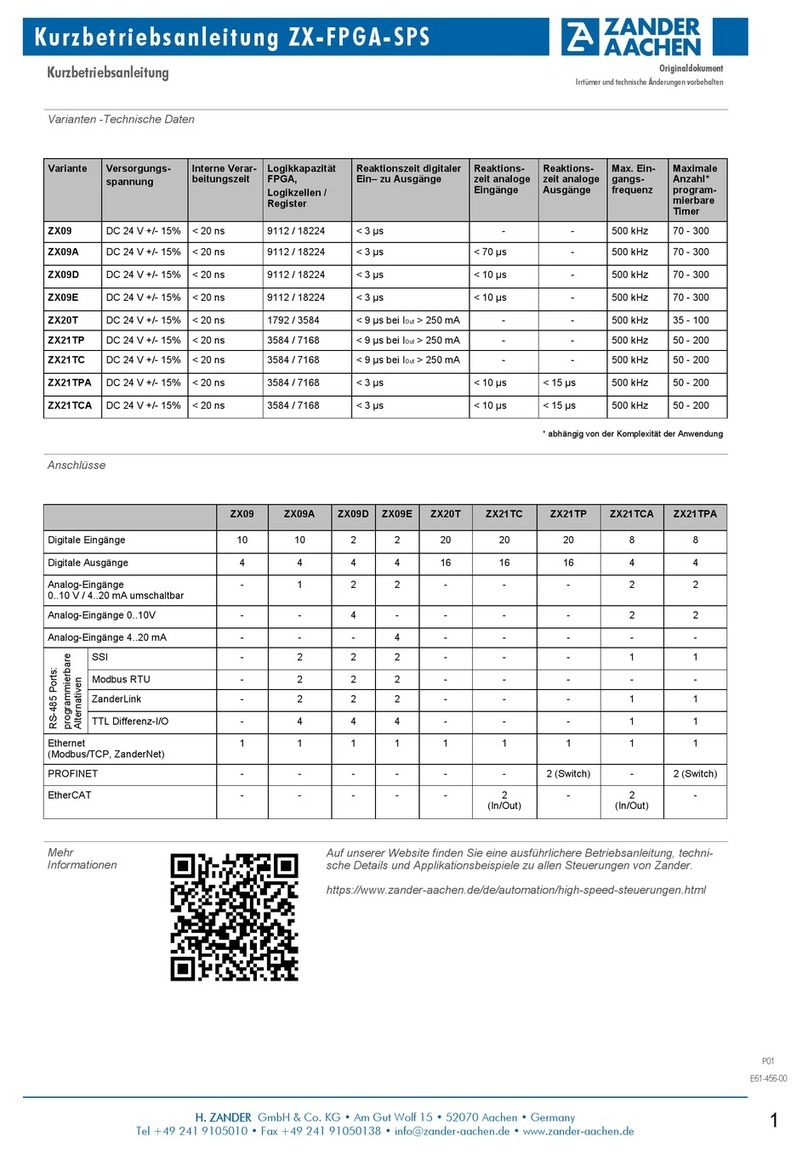

H. ZANDER GmbH & Co. KG • Am Gut Wolf 15 • 52070 Aache • Germa y

Tel +49 (0)241 9105010 • Fax +49 (0)241 91050138 • info@zander-aachen.de • www.zander-aachen.de 1

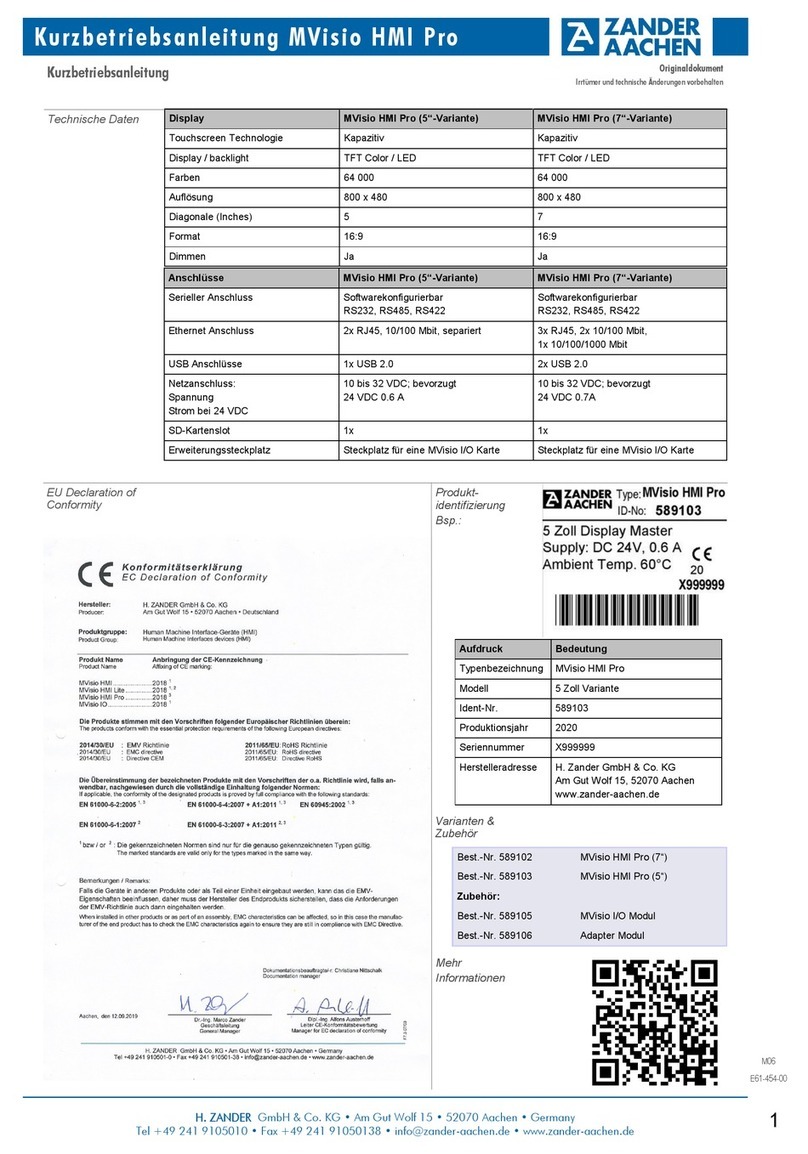

Time-Del. Emergency Stop Safety Relay SR4C

M11

Ver. A

E61-140-00

Operating Instructions English translation

Errors and technical changes reserved

• Cyclical monitoring of the output contacts

• Indication of the switching state via LED

• 2 start behaviors possible:

- monitored manual start

- automatic start

• Short circuit and earth fault monitoring

• Up to L e, SILCL 3, category 4

SR4C is an emergency stop safety relay com ination that

com ines non-time-delayed and time-delayed contacts in a very

compact housing. This permits dangerous components of a

system to e switched off quickly and safely in an emergency

situation. At the same time, other circuits can continue to e

supplied with voltage for up to 30 seconds to allow a tool to e

moved to its idle position or to rake following parts, for

example.

• 4 positively driven safety relays contacts. ossible vari-

ants:

- 3 non-time-delayed and 1 time-delayed contact

- 2 non-time-delayed and 2 time-delayed contact

- 1 non-time-delayed and 3 time-delayed contact

• Continuously adjustable time delay (1 to 30s).

• Connection of:

- Emergency stop buttons

- Safety switches

- Non-contacts safety switches

- OSSD-Outputs

• 1- or 2-channel activation possible

• Feedback loop for monitoring downstream contactors or

expansion modules

Function The moving parts of a machine or system can be quickly

and safely stopped in case of danger with the non-time-

delayed contacts of the SR4C Safety contacts with time-

delay switch-off are also integrated into the SR4C. They

are used whenever it is safer to keep supplying voltage to

parts of a machine after the emergency stop switch is

operated.

t is ensured that a single fault or malfunction does not lead

Installation As per D N EN 60204-1, the device is intended for installa-

tion in control cabinets with a minimum degree of protection

of P54. t is mounted on a 35 mm D N rail according to D N

EN 60715 TH35.

Safety

recautions

Fig. 2 Installation/removal

to a loss of the safety function and that every fault is detect-

ed by cyclical self-monitoring no later than when the system

is switched off and switched on again.

The time-delay contacts are activated at the same time as

the non-time-delay contacts; however, when the emergency

stop button is pressed, the contacts are only deactivated

after the time set on the potentiometer (1 … 30s).

During timeout, no power-loss is accepted.

Electrical

Connection

• Consider the information in the section "Techn. data"

• A safe transformer according to EN 61558-2-6 or a

power supply unit with electrical isolation from the mains

must be connected

• External fusing of the safety contacts must be provided

• f the device does not function after commissioning, it

must be returned to the manufacturer unopened. Ope-

ning the device will void the warranty

• Use adequate protective circuit for inductive loads (e.g.

free-wheeling diode)

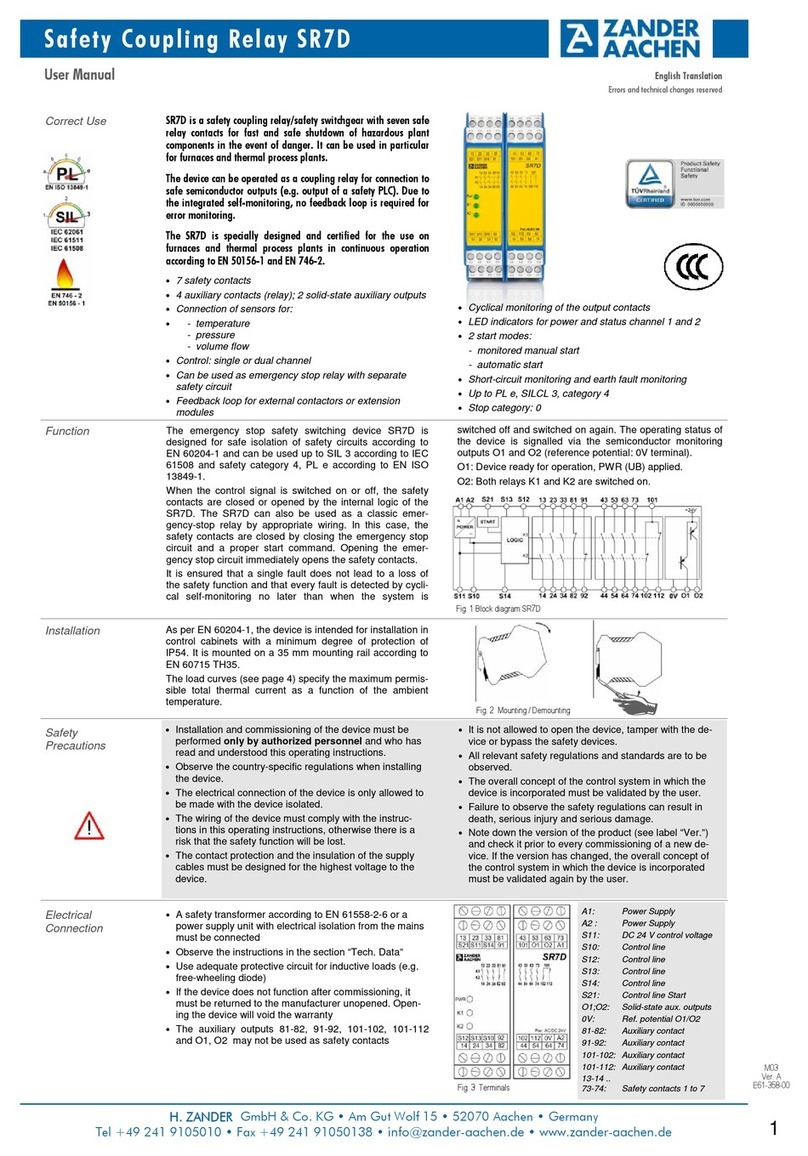

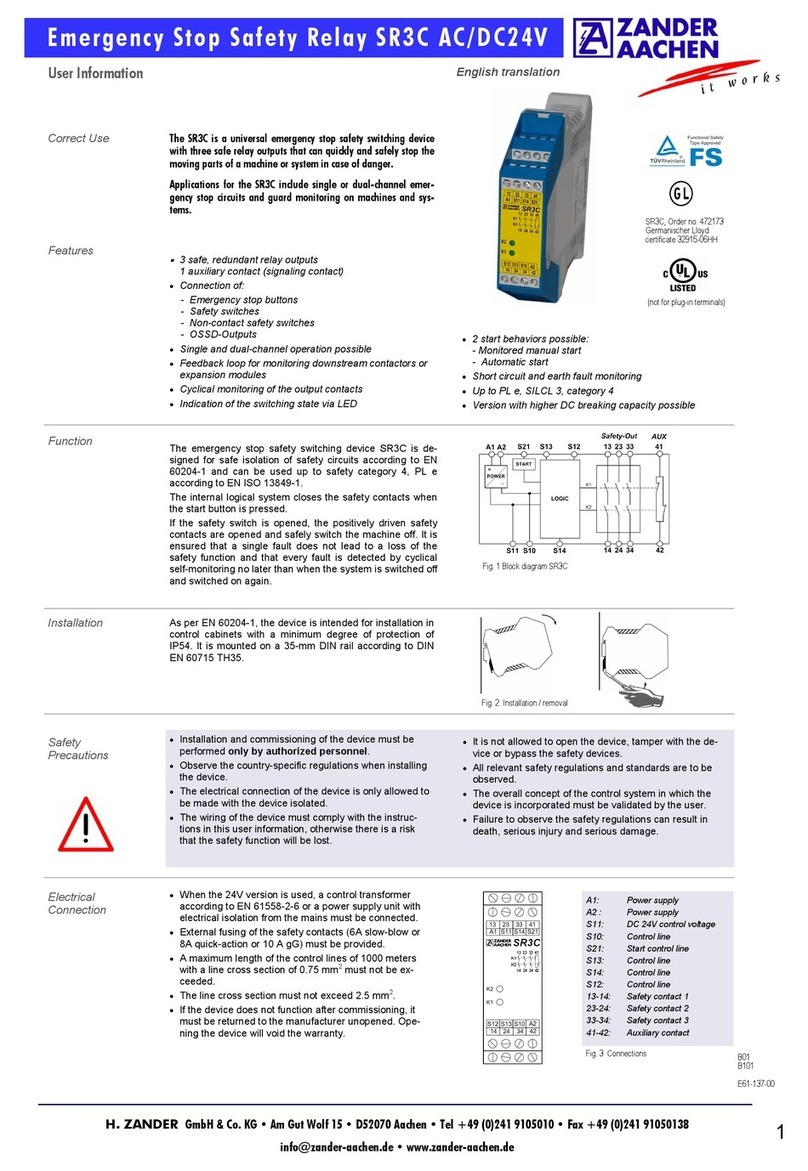

Fig. 3 Connections nd non-time delayed; d time-delayed

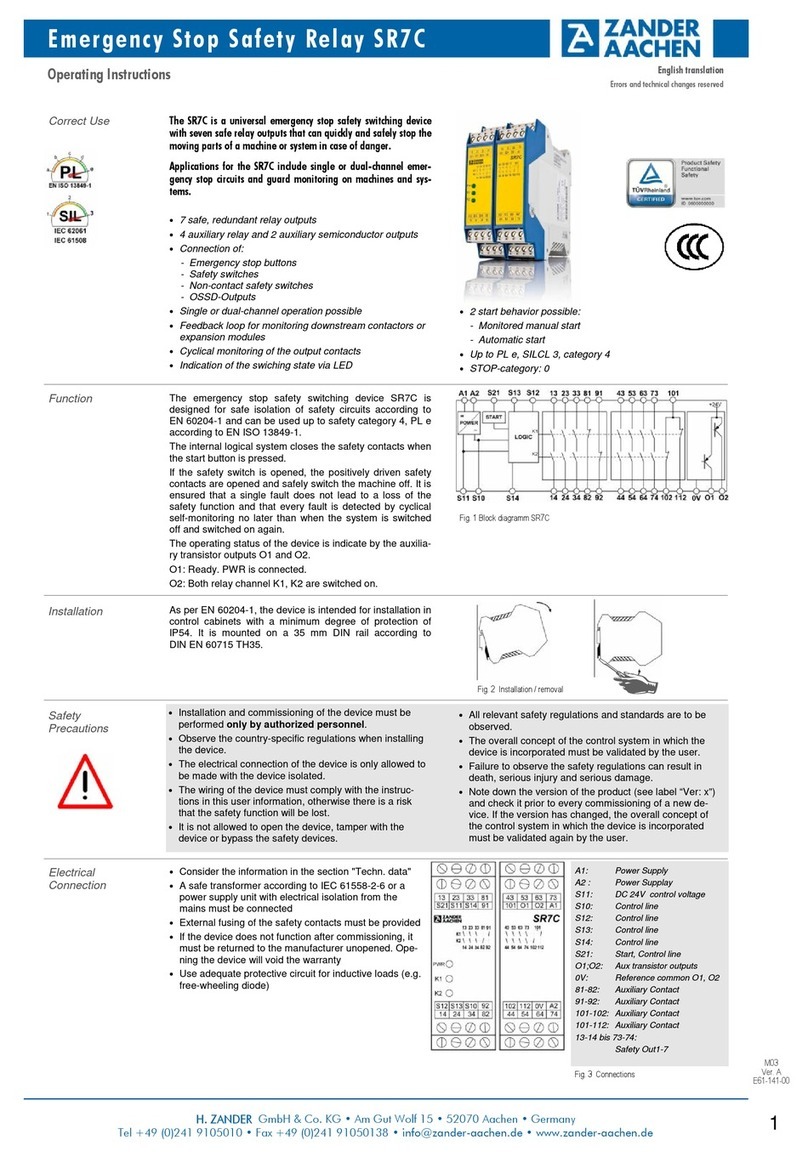

Fig. 1 Block diagram: SR4C (1nd/3d); SR4C (2nd/2d); SR4C (3nd/1d)

A1: ower supply

A2 : ower supply

S11: DC 24 V control voltage

S10: Control line

S12: Control line

S13: Control line

S14: Control line

S21: Start control line

13-14: Safety contact 1 (nd)

23-24/27-28: Safety contact 2 (d / nd)

33-34/37-38: Safety contact 3 (d / nd)

47-48: Safety contact 4 (d)

• All relevant safety regulations and standards are to be

observed.

• The overall concept of the control system in which the

device is incorporated must be validated by the user.

• Failure to observe the safety regulations can result in

death, serious injury and serious damage.

• Note down the version of the product (see label “Ver: x”)

and check it prior to every commissioning of a new de-

vice. f the version has changed, the overall concept of

the control system in which the device is incorporated

must be validated again by the user.

• nstallation and commissioning of the device must be

performed only by authorized personnel.

• Observe the country-specific regulations when installing

the device.

• The electrical connection of the device is only allowed to

be made with the device isolated.

• The wiring of the device must comply with the instruc-

tions in this user information, otherwise there is a risk

that the safety function will be lost.

• t is not allowed to open the device, tamper with the

device or bypass the safety devices.

Correct Use