Page 1

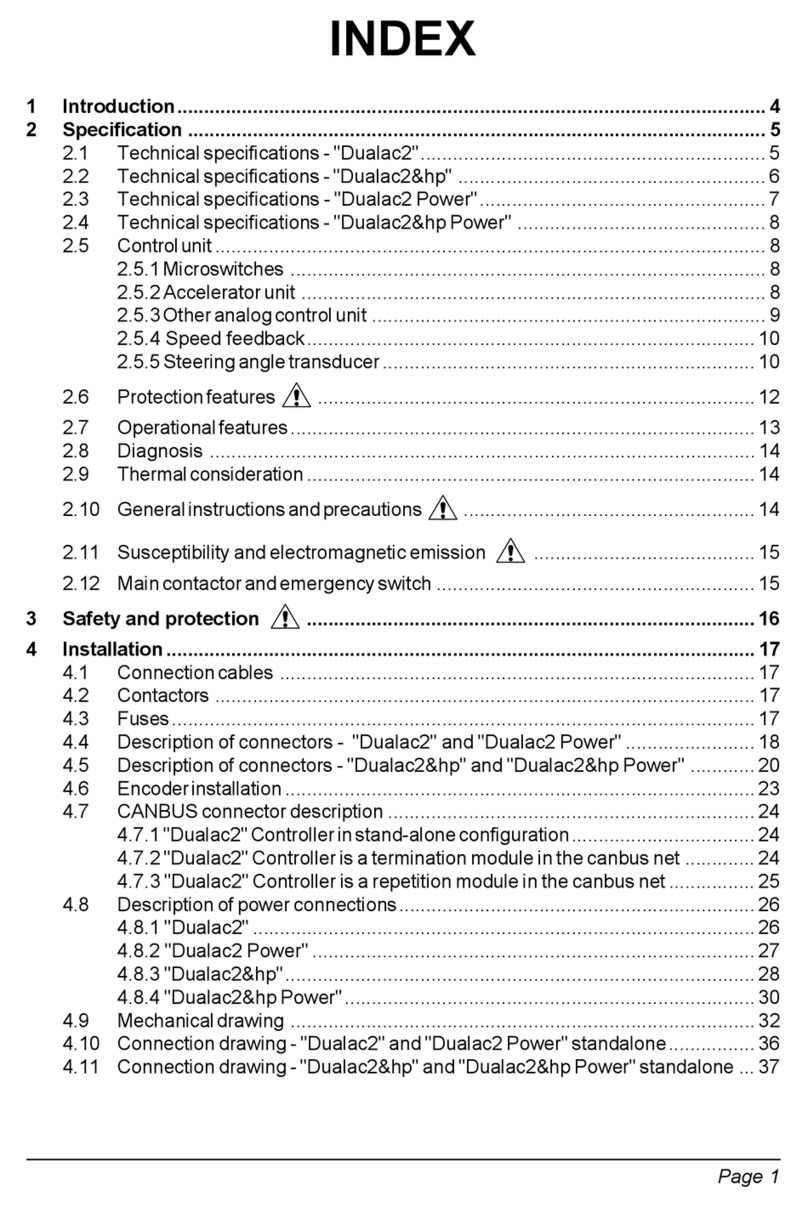

INDEX

Page

1 Introduction.................................................................................................... 3

2 Specification .................................................................................................. 3

2.1 AC-3 Technical specifications ................................................................ 3

2.2 AC-4 Technical specifications ................................................................ 3

2.3 Block diagram ........................................................................................ 4

2.4 Control unit ............................................................................................. 4

2.4.a Microswitches ............................................................................... 4

2.4.b Accelerator unit ............................................................................. 4

2.4.c Other analog control unit ................................................................ 5

2.4.d Speed feedback............................................................................ 5

2.5 Protection features .......................................................................... 6

2.6 Operational features ............................................................................... 7

2.7 Diagnosis .............................................................................................. 8

2.8 Thermal consideration ............................................................................ 8

2.9 General instructions and precautions . .............................................. 8

2.10 Susceptibility and electromagnetic emission .................................. 9

2.11 Main contactor and emergency switch .................................................... 9

3 Installation .................................................................................................... 10

3.1 Connection cables ............................................................................... 10

3.2 Contactors ........................................................................................... 10

3.3 Fuses ................................................................................................... 10

3.4 Description of connectors - Traction configuration ............................... 11

3.4.a Amp Saab connector ................................................................... 11

3.4.b Molex Minifit connectors .............................................................. 13

3.5 Description of connectors - Pump configuration .................................... 15

3.5.a Amp Saab connector ................................................................... 15

3.5.b Molex Minifit connectors .............................................................. 17

3.6 Encoder installation .............................................................................. 19

3.7 Description of power connections......................................................... 20

3.8 AC-3 Mechanical drawing .................................................................... 21

3.9 AC-4 Mechanical drawing .................................................................... 22

3.10 Connection drawing - Traction configuration ......................................... 23

3.10.a Amp Saab connector ................................................................ 23

3.10.b Molex Minifit connectors ........................................................... 24

3.11 Connection drawing - Pump configuration ............................................ 25

3.11.a Amp Saab connector ................................................................ 25

3.11.b Molex Minifit connectors ........................................................... 26

3.12 Connection drawing - Combi configuration ........................................... 27

3.12.a Amp Saab connector ................................................................ 27

3.12.b Molex Minifit connectors ........................................................... 28