Page 2

5 Programming & Adjustments using Digital Console ......................................... 38

5.1 Adjustments via Console ............................................................................... 38

5.2 Description of Console & Connection ............................................................ 38

5.3 Description of Standard Console Menu ......................................................... 39

5.3.1 "Dualac2" and "Dualac2 Power" menu configuration ............................ 39

5.3.1.a Master ............................................................................................... 39

5.3.1.b Slave ................................................................................................. 40

5.3.2 "Dualac2&hp" and "Dualac2&hp Power" menu configuration ................ 41

5.3.2.a Master ............................................................................................... 41

5.3.2.b Slave ................................................................................................. 42

5.4 Function configuration ................................................................................... 43

5.4.1 "Dualac2" and "Dualac2 Power" - Master ............................................. 43

5.4.2 "Dualac2" and "Dualac2 Power" - Slave ............................................... 46

5.4.3 "Dualac2&hp" and "Dualac2&hp Power" - Master ................................ 47

5.4.4 "Dualac2&hp" and "Dualac2&hp Power" - Slave .................................. 47

5.5 Parameter regulation ..................................................................................... 52

5.5.1 "Dualac2" - Master ............................................................................... 52

5.5.2 "Dualac2" - Slave ................................................................................. 53

5.5.3 "Dualac2&hp" - Master ......................................................................... 54

5.5.4 "Dualac2&hp" - Slave ........................................................................... 55

5.6 Programming console functions .................................................................... 60

5.6.1 Functional configuration (see 5.4) ......................................................... 60

5.6.2 Parameter programming (see 5.5) ....................................................... 60

5.6.3 "Dualac2" and "Dualac2 Power" Tester: user can verify the state of the

following parameters: .................................................................................... 60

5.6.4 "Dualac2&hp" and "Dualac2&hp Power" Tester: user can verify the state

of the following parameters: ........................................................................... 61

5.6.5 Save function (for storing data) --> only with Pc-console ........................ 61

5.6.6 Restore function (for downloading parameters to another controller) -->

only with Pc-console ...................................................................................... 61

5.6.7 Display of the last 5 alarms including hour-meter value and temperature at

the moment of the alarm. ............................................................................... 61

5.6.8 Accelerator range programming ........................................................... 61

5.6.9 See the console manual for a detailed description of function and param-

eters.............................................................................................................. 61

5.7 Sequence for Ac Inverter Traction setting....................................................... 62

5.8 Tester: description of the function .................................................................. 63

5.8.1 "Dualac2" and "Dualac2 Power" - Master ............................................. 63

5.8.2 "Dualac2" and "Dualac2 Power" - Slave ............................................... 64

5.8.3 "Dualac2&hp" and "Dualac2&hp Power" - Master ................................ 65

5.8.4 "Dualac2&hp" and "Dualac2&hp Power" - Slave .................................. 66

6 Other functions ..................................................................................................... 69

6.1 Save and Restore function............................................................................. 69

6.2 Description of Alarms menu .......................................................................... 70

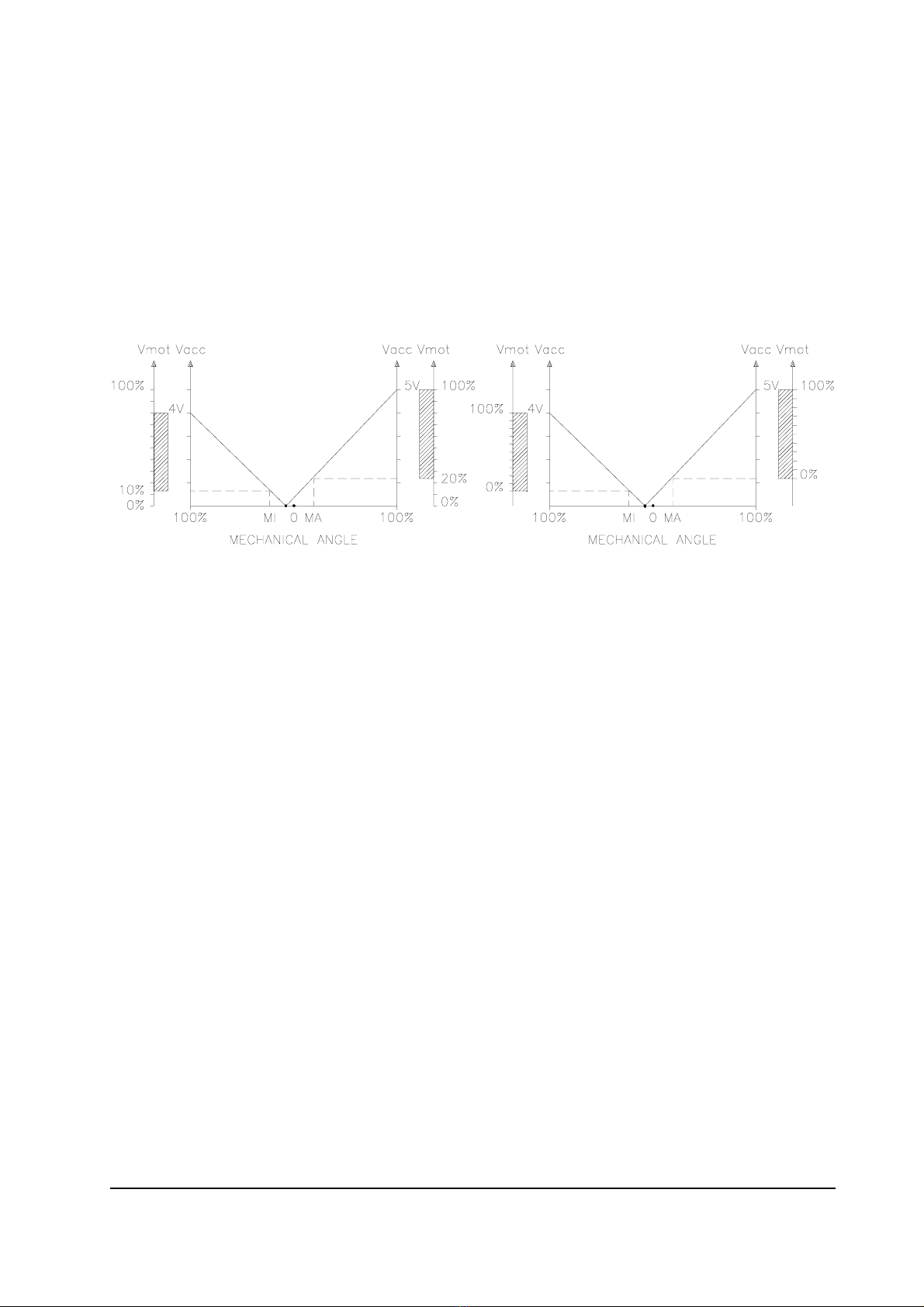

6.3 Description of Console Program Vacc function ............................................. 71