POWERING POSITIVE CHANGE

MAXEON SOLAR TECHNOLOGIES, LTD.

Safety and Installation Instructions - Document 539821 Rev.D

© 2023 Maxeon Solar Technologies, Ltd. All rights reserved. Specifications included in these instructions are subject to change without notice. “MAXEON” and “POWERING POSITIVE CHANGE” are registered trademarks in certain

countries. View warranty, patent and trademark information at https:/corp.maxeon.com/trademarks. Page | 4

No Maxeon module should be mounted at a site where it may be subject to

direct contact with salt water, or other aggressive environment.

Modules should not be installed near flammable liquids, gases, or locations with

hazardous materials; or moving vehicles of any type.

Performance Series Mounting Orientation

Commercial Performance Series (P-Series) modules are designed to perform

better if installed in landscape orientation. In landscape orientation, P-series

modules maintain higher power in conditions of row-to-row shading and/or edge

soiling.

5.2 Mounting Configurations

Modules integrated into or mounted over a roofing system must be mounted

over a fire-resistant roof covering rated for the application. Modules may be

mounted at any angle, from horizontal to vertical. To reduce soiling, modules

should be mounted at a minimum of 5 degrees.

Specific information on module dimensions and the location of mounting and

grounding holes is provided in Appendix. The system installer is responsible for

the determination of location-specific load requirements.

It should be noted that watertightness is not ensured by Maxeon, therefore, if

water management is required, the mounting system should be designed

accordingly.

The module is only CSA Listed for use when its factory frame is fully intact. Do

not remove or alter the module frame, and do not create additional mounting

holes because doing so may compromise the integrity of the frame.

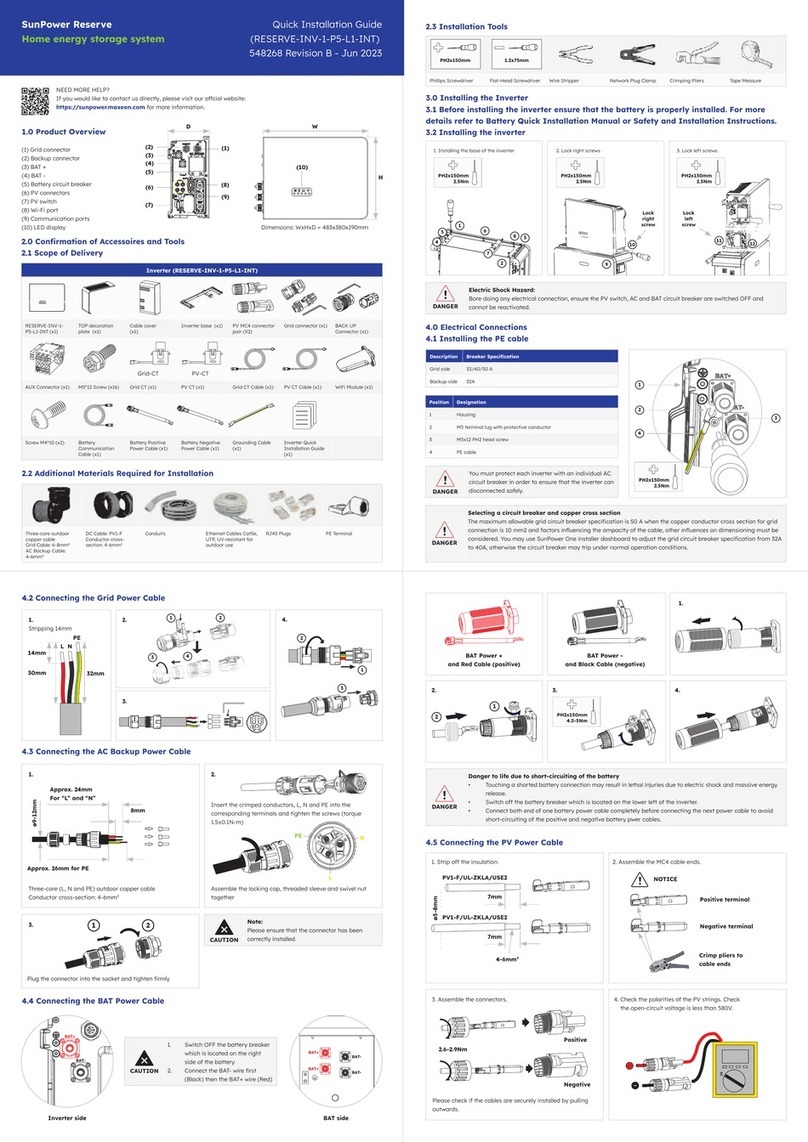

Modules may be mounted using the following methods only:

1) Frame Holes: Secure the module to the structure using the factory

mounting holes. Four 1/4″stainless steel bolts, with nuts, washers, and lock

washers are recommended per module; tightened to a min. torque of 10 in-

lb. This method has been certified by a third-party organization according to

UL 1703. For frame hole mounting, modules must be secured using the

holes shown in Appendix.

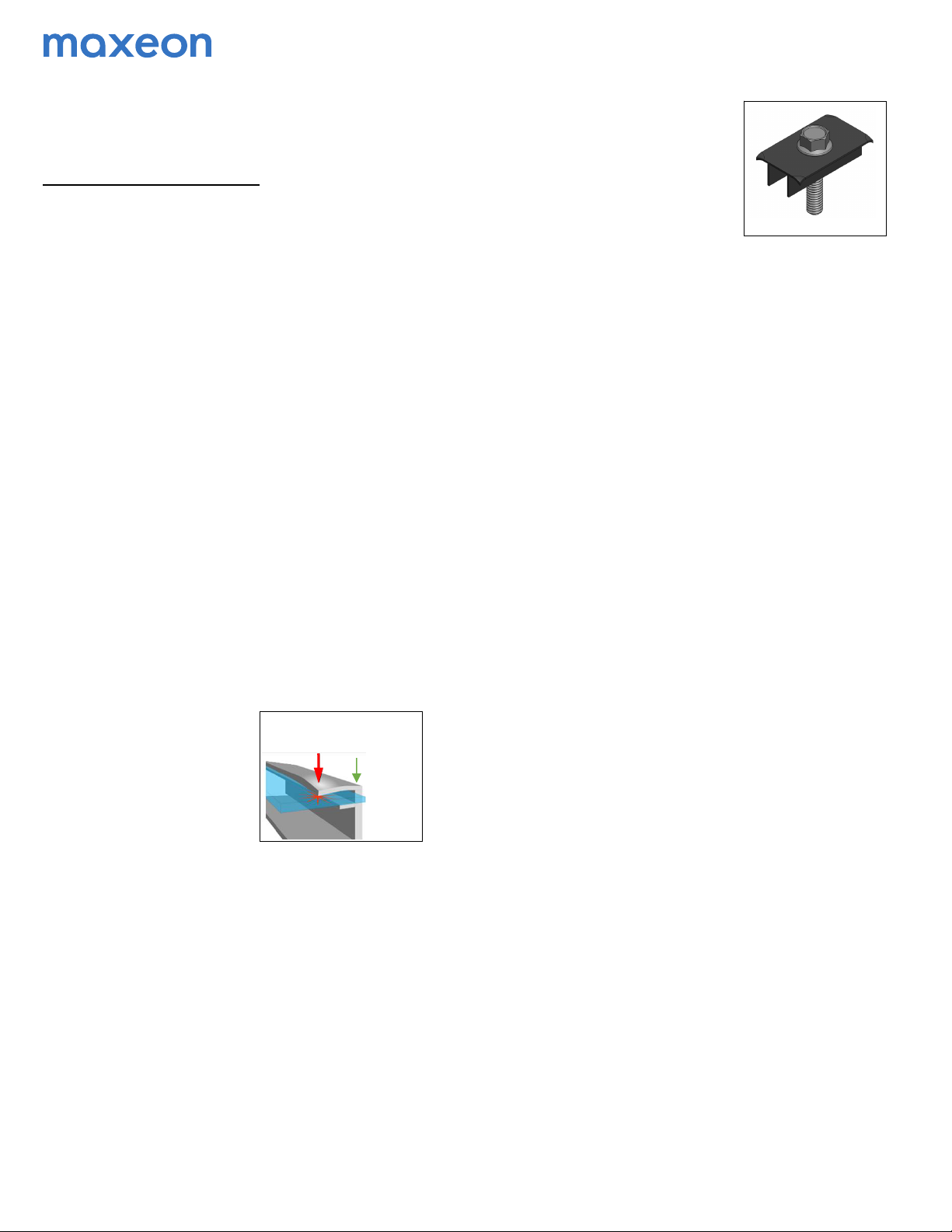

2) Clamps: Mount the module with the opposite clamps on the longer and/or

shorter sides of the module. Installers should ensure the clamps are of

sufficient strength to allow for the maximum design pressure of the

module. Clamps are not provided by Maxeon. Clamps that secure to the top

of the frame must not deform the top flange. Clamps must apply force

collinear with the ‘wall’ of the

module frame and not only to the

top flange. Clamps or installation

procedures that put excessive

force on the top flange will

deform the frame, void the

module warranty and risk glass

breakage. Figure 1a illustrates

locations for top frame clamp

force. When clamping to the

module frame, torque should never exceed 132 in-lbs (15 Nm) to reduce

chances of frame deformation and/or glass breakage. If the clamp

manufacturer recommends a specific torque value which is lower than 132

in-lbs (15 Nm), the installer should use the clamp manufacturer’s torque

value. If the clamp manufacturer recommends a specific torque value

which is higher than 132 in-lbs (15 Nm), the installer should contact the

clamp manufacturer for acceptance of the 132 in-lbs (15 Nm) maximum

torque value or to find alternative clamps. A calibrated torque wrench must

be used. Mounting systems should be evaluated for compatibility before

installing specially when the system is not using Clamps.

Minimum clamp width allowance is ≥35mm, and for corner clamping the

minimum clamp width is: ≥50mm. Clamps should not be in contact with the

front glass and clamps should not deform the frame.

Maxeon does not recommend nor endorse the application on the modules

of clamps which, as part of their grounding or earthing function, have teeth

or claw features (see Figure 2) which may, individually or cumulatively,

cause the module breakage due to (and without limitation):

i. the grounding features touching the

front glass which is incorporated into

the module due to the position of such

grounding feature,

ii. the shape, the position or the number

of the grounding features deforming

the module top frame, or

iii. the clamp being over-torqued during

the installation.

Maxeon shall not be liable for any damages or losses whatsoever arising

from the use by the Installer of any such clamps on its modules, and

disclaims all warranties, express or implied, applicable to those modules

should they be damaged in any way by such clamps. Therefore, the use of

the above mentioned clamps by the Installer is at the Installer's sole risks.

5.3 Ground Mount Applications for Bifacial modules

Various environmental and installation parameters affect bifacial gain. Albedo is a

measure of the amount of light reflected from the ground surface. A higher

albedo factor will increase irradiance on the backside and result in higher bifacial

gain of the module. The surface conditions, month of the year, time of day, GHI

and DNI both influence the amount of incident rearside irradiance.

Maxeon recommends to check with solar module mounting hardware supplier in

order to determine the Structure Shading factor of your particular installation.

The Structure Shading Factor varies with racking system design, irradiance,

albedo and height of module installation above ground and has an overall impact

on the rear side irradiance mismatch.

The Rearside mismatch losses are proportional to the albedo, height of the

modules above ground and structure shading factor. The irradiance non-

uniformity on the rearside results in mismatch generally as the albedo increases

and installation height of the modules are lower to the ground.

5.4 Rooftop Applications for Bifacial modules

Bifacial modules use direct, reflected or diffuse sunlight at the rearside to

generate additional power. Therefore, it is recommended to use bifacial modules

installed on flat roof applications.

In order to maximize the bifacial gain at the rooftop applications the following

parameters listed below should be considered:

•Surface Albedo

•Roof Integrity

•Module Tilt Angle

•Module Elevation

•Structural Backside Shading

The bifacial modules can be mounted both landscape or portrait orientation as

shown in Appendix section.

When installing a bifacial module on a roof, ensure that the roof construction and

the structural load calculations of the building are suitable.

Bifacial gain tends to be most effective with a higher tilt angle.

As the tilt angle and the module elevation from the underlying surface increases,

more reflected light and diffuse light can be captured by the module.

The mounting rails shall be designed to limit the rear side shading as much as

possible.

5.5 Bifacial Electrical Considerations

The overall electrical bifacial gain is determined by the combination of surface

albedo, irradiance, module tilt angle, shading losses from the rearside, rearside

mismatch and module elevation above ground. Please refer to the Maxeon

datasheet for the electrical outputs with respect to the overall bifacial gain.

Please utilize a suitable performance software package to simulate the overall

bifacial gain

5.6 Handling of Modules during Installation

Do not place modules face forward in direct contact with abrasive surfaces like

roofs, driveways, wooden pallets, railings, stucco walls, etc…

The module front surface glass is sensitive to oils and abrasive surfaces, which

may lead to scratches and irregular soiling.

Force must not deform

top frame flange or

glass may break

Figure 1a: Clamp Force Locations

Force can

be applied

in line with

frame wall

Fi

ure 2