AFDZP0BA – VCM Zapi 2uC - User Manual Page - 3/54

Contents

1INTRODUCTION ...................................................................................................................5

2SPECIFICATION...................................................................................................................7

2.1Technical specifications VCM Standard .....................................................................7

2.2Technical specifications VCM Premium ....................................................................7

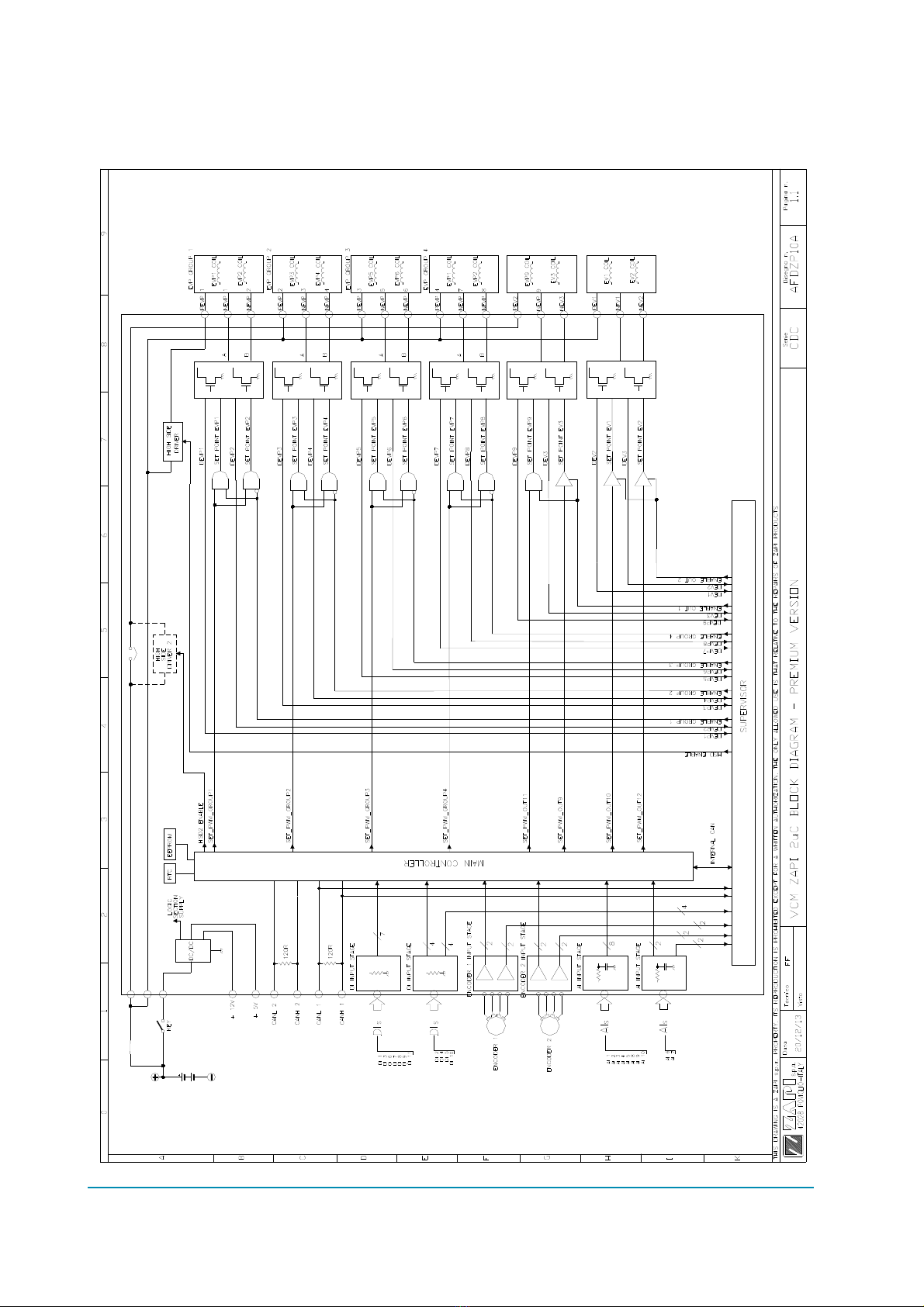

3BLOCK DIAGRAM................................................................................................................8

4SPECIFICATION FOR THE I/O INTERACES.......................................................................9

4.1Digital inputs ...............................................................................................................9

4.1.1DI1 ÷ DI11 technical details ..........................................................................9

4.1.2Microswitches ...............................................................................................9

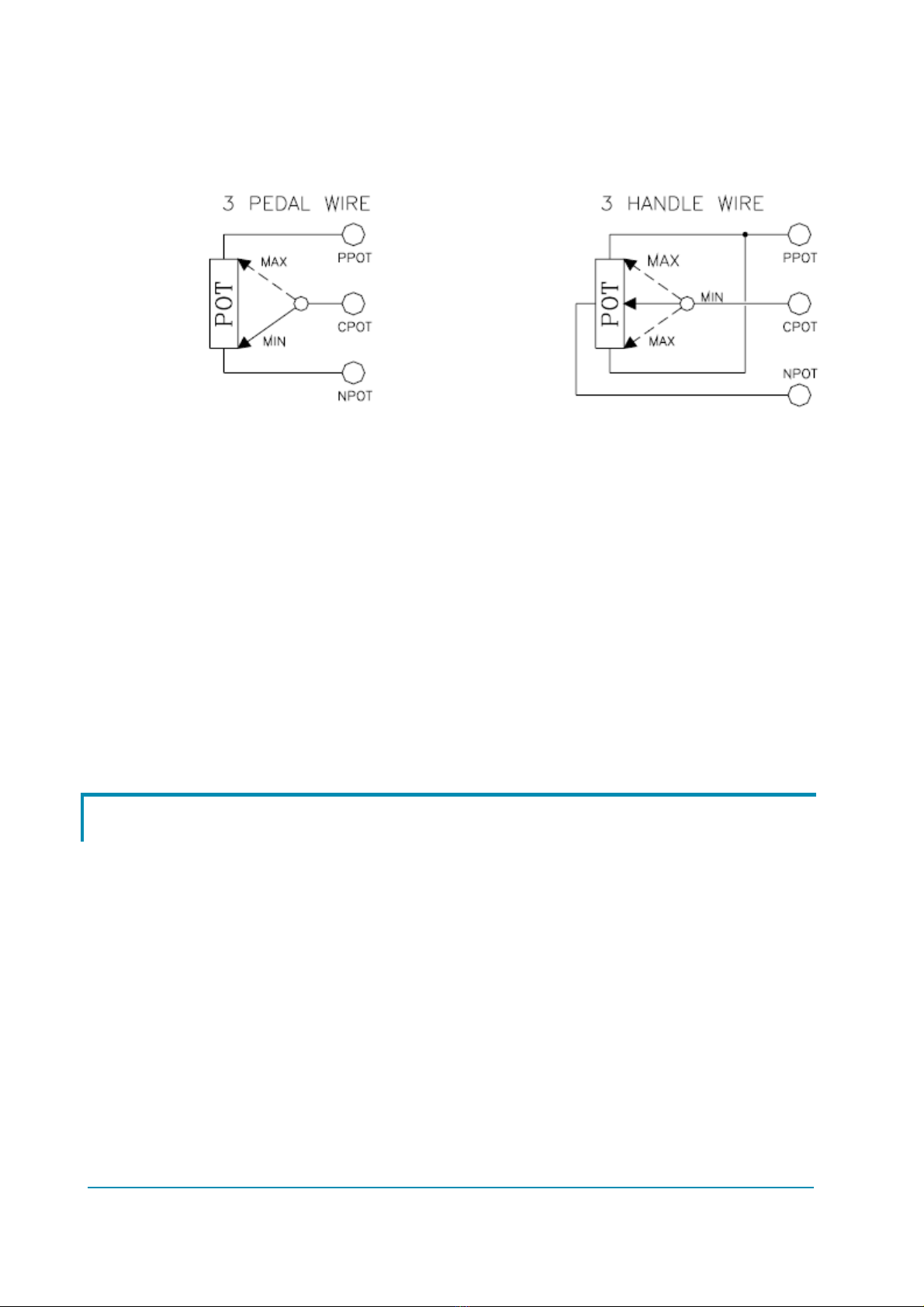

4.2Analog inputs ..............................................................................................................9

4.3Outputs .....................................................................................................................10

4.4Incremental encoder .................................................................................................11

4.5CAN BUS..................................................................................................................12

5ADDITIONAL FEATURES ..................................................................................................14

5.1Real Time Clock .......................................................................................................14

5.2High Side Driver........................................................................................................14

6INSTALLATION HINTS.......................................................................................................15

6.1Material overview......................................................................................................15

6.1.1Connection cables ......................................................................................15

6.1.2Fuses ..........................................................................................................15

6.2Installation of the hardware.......................................................................................15

6.2.1Wirings: CAN connections and possible interferences ...............................16

6.2.2Wirings: I/O connections .............................................................................18

6.2.3Insulation of truck frame..............................................................................18

6.3Protection features....................................................................................................18

6.3.1Hardware Protection ...................................................................................18

6.3.2Safety Features...........................................................................................18

6.3.3Double microcontroller architecture ............................................................19

6.4EMC..........................................................................................................................19

7DESCRIPTION OF THE CONNECTORS............................................................................21

7.1CNA Ampseal 35 poles.............................................................................................21

7.2CNB Ampseal 23 poles (only for VCM PREMIUM) ..................................................23

8DRAWINGS.........................................................................................................................24

8.1Mechanical drawing ..................................................................................................24

8.1.1VCM STANDARD .......................................................................................24

8.1.2VCM PREMIUM ..........................................................................................25

8.2Functional drawing....................................................................................................26

8.2.1VCM STANDARD .......................................................................................26

8.2.2VCM PREMIUM ..........................................................................................27

9PROGRAMMING & ADJUSTMENTS .................................................................................28

9.1Description of programmable functions ....................................................................28

9.2Description of the TESTER function .........................................................................35

9.3Description of the console SAVE function ................................................................37

9.4Description of the console RESTORE function ........................................................38

9.5Description of the throttle regulation .........................................................................38

9.6Description of the battery charge detection setting...................................................39

9.7Description of ALARMS menu ..................................................................................40