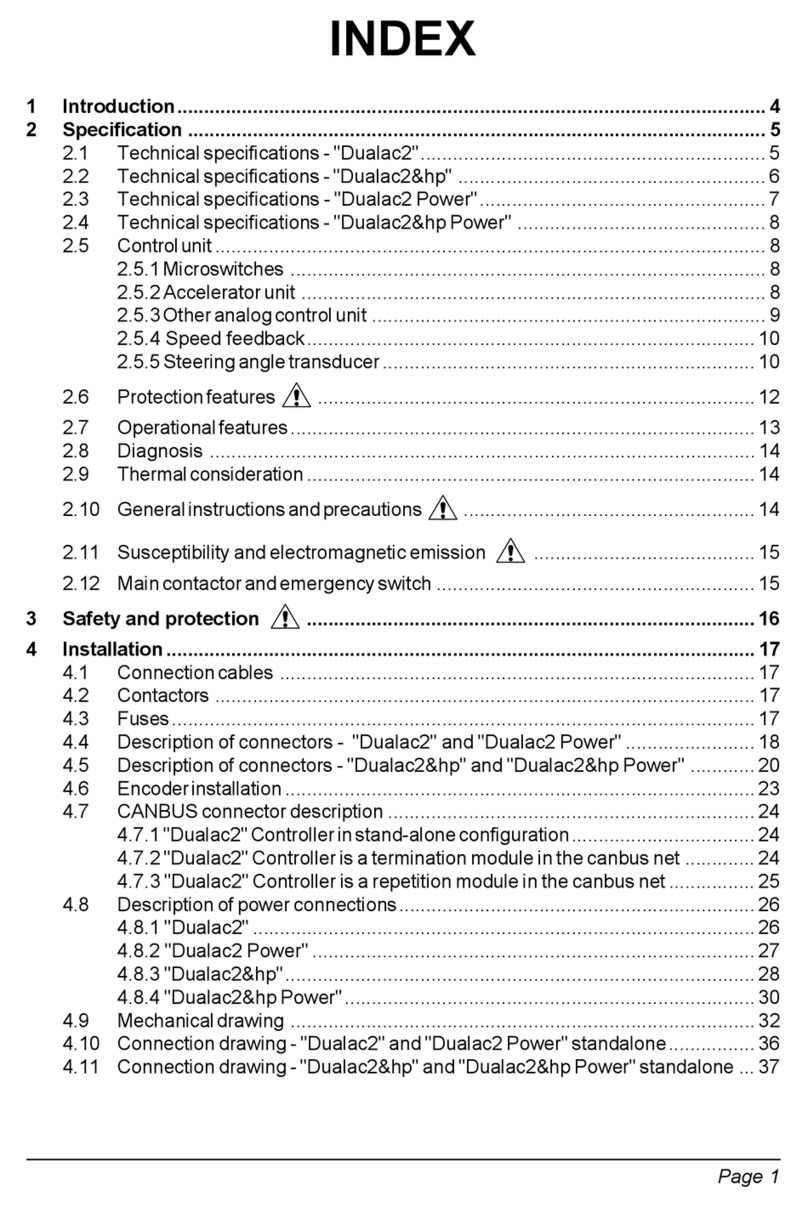

Contents

1INTRODUCTION ...................................................................................................................6

2SPECIFICATION...................................................................................................................7

2.1 Technical specifications..............................................................................................7

2.2 Block diagrams ...........................................................................................................7

3SPECIFICATION FOR THE INPUT DEVICES FILLING UP THE INSTALLATION KIT.......8

3.1 Digital inputs ...............................................................................................................8

3.1.1 DIs technical details – 24 V system ..............................................................8

3.1.2 DIs technical details – 48 V system ..............................................................8

3.1.3 Microswitches ...............................................................................................8

3.2 Analog unit..................................................................................................................9

3.3 Other analog control unit ............................................................................................9

3.4 Analog motor thermal sensor input...........................................................................10

3.5 Speed feedback........................................................................................................10

4INSTALLATION HINTS.......................................................................................................11

4.1 Material overview......................................................................................................11

4.1.1 Connection cables ......................................................................................11

4.1.2 Contactors...................................................................................................11

4.1.3 Fuses ..........................................................................................................12

4.2 Installation of the hardware.......................................................................................12

4.2.1 Positioning and cooling of the controller .....................................................12

4.2.2 Wirings: power cables.................................................................................13

4.2.3 Wirings: CAN connections and possible interferences ...............................13

4.2.4 Wirings: I/O connections .............................................................................15

4.2.5 Connection of the encoder..........................................................................16

4.2.6 Main contactor and key connection ............................................................17

4.2.7 Insulation of truck frame..............................................................................18

4.3 Protection and safety features ..................................................................................19

4.3.1 Protection features......................................................................................19

4.3.2 Safety Features...........................................................................................20

4.4 EMC..........................................................................................................................20

4.5 Various suggestions .................................................................................................22

5OPERATIONAL FEATURES ..............................................................................................23

5.1 Diagnosis ..................................................................................................................23

6DESCRIPTION OF THE CONNECTORS............................................................................24

6.1 Connectors of the logic .............................................................................................24

6.1.1 CNA connector: AmpSaab Version.............................................................25

6.1.2 CNA connector: AmpSeal version ..............................................................26

6.2 Description of power connections.............................................................................28

7DRAWINGS.........................................................................................................................29

7.1 Mechanical drawing ..................................................................................................29

7.2 Connection drawing ..................................................................................................30

7.2.1 AmpSaab version........................................................................................30

7.2.2 AmpSeal version.........................................................................................31

8ONE SHOT INSTALLATION PROCEDURE.......................................................................32

8.1 Sequence for Ac Inverter traction setting..................................................................33

9PROGRAMMING & ADJUSTMENTS USING DIGITAL CONSOLE...................................35

9.1 Adjustments via console ...........................................................................................35

AEQZP0BA – COMBI AC1 - User Manual Page - 3/86