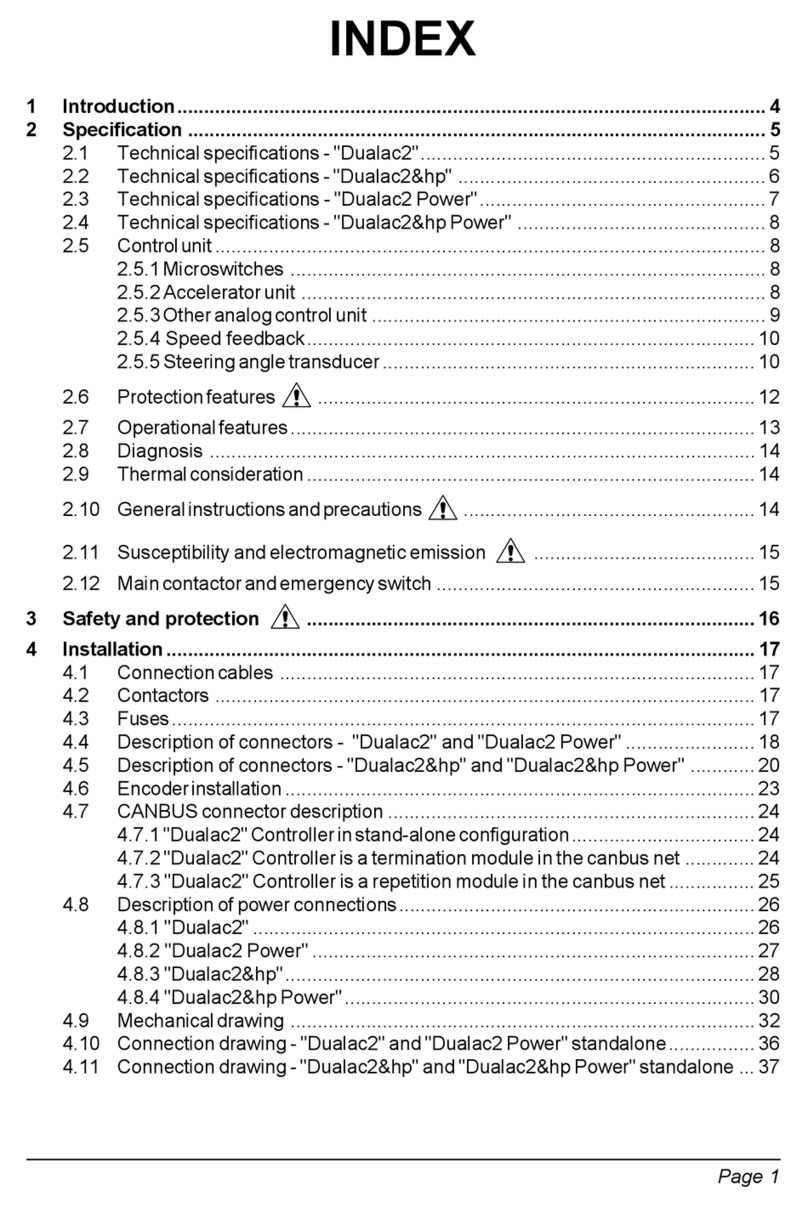

Contents

1INTRODUCTION ...................................................................................................................5

2SPECIFICATION...................................................................................................................6

2.1 Technical specifications..............................................................................................6

2.2 Block diagram.............................................................................................................6

2.3 Control unit .................................................................................................................6

2.3.1 Microswitches ...............................................................................................6

2.3.2 Accelerator unit.............................................................................................7

2.3.3 Other analog control unit...............................................................................7

2.3.4 Speed feedback............................................................................................8

2.4 UProtection features .................................................................................................8

2.5 Operational features...................................................................................................8

2.6 Diagnosis....................................................................................................................9

2.7 Thermal consideration..............................................................................................10

2.8 UGeneral instructions and precautions...................................................................10

2.9 USusceptibility and electromagnetic emission........................................................10

2.10 Main contactor and emergency switch .....................................................................10

3USAFETY AND PROTECTION.......................................................................................12

4INSTALLATION...................................................................................................................13

4.1 Connection cables....................................................................................................13

4.2 Contactors ................................................................................................................13

4.3 Fuses........................................................................................................................13

4.4 Description of connectors - Traction configuration ..................................................14

4.5 Description of connectors - Pump configuration.......................................................16

4.6 Encoder installation ..................................................................................................18

4.7 Description of power connections.............................................................................20

4.8 Mechanical drawing..................................................................................................21

4.9 Connection drawing - Traction configuration............................................................22

4.10 Connection drawing - Pump configuration................................................................23

4.11 Connection drawing - Combi configuration...............................................................24

5PROGRAMMING & ADJUSTMENTS USING DIGITAL CONSOLE...................................25

5.1 Adjustments via Console..........................................................................................25

5.2 Description of Console & Connection.......................................................................25

5.3 Description of Standard Console Menu....................................................................26

5.3.1 Traction configuration .................................................................................26

5.3.2 Pump configuration.....................................................................................27

5.4 Function configuration ..............................................................................................27

5.4.1 Traction.......................................................................................................27

5.4.2 Pump...........................................................................................................31

5.5 Parameter regulation: Traction configuration............................................................38

5.6 Parameter regulation: Pump configuration...............................................................39

5.7 Programming console functions ...............................................................................41

5.8 Sequence for Ac Inverter Traction setting ................................................................42

5.9 Sequence for Ac Inverter Pump setting....................................................................43

5.10 Tester: description of the function; Traction configuration........................................43

5.11 Tester: description of the function; Pump configuration............................................45

6OTHER FUNCTIONS ..........................................................................................................48

6.1 Description of the Console “SAVE” function.............................................................48

ADEZP0AE - AC-2 INVERTER - User Manual Page - 3/64