Please refer to design drawings for proposed ducting layout.

5 x 125mm nominal diameter spigots are provided for connection to ducting. Ductwork should be securely

connected to spigots. Failure to do this will cause unnecessary air leakage and impair performance.

If applicable, Fire dampers MUST BE FITTED in accordance with Part B of the Building Regulations.

Rigid Ducting - Install using the least number of fittings to minimise resistance to air flow. Where possible, final

connection to grilles and unit should be made with a flexible connection. Mechanically fix ducts using metal

jubilee clips or heavy duty plastic cable ties and appropriate non-hardening sealant for air tightness.

WARNING: Do not use screws for connection and ensure jubilee clips are not over tightened.

Flexible Ducting - Ensure ducting lengths are kept to a minimum and ducting is pulled taut so that it is smooth

and straight. Where bends are necessary and where ducting is run in restricted areas, ensure the ducting is not

crushed. Mechanically fix ducts using metal jubilee clips or heavy duty plastic cable ties and tape seal for air

tightness.

WARNING: Should be in accordance with Building Regulations.

Ensure any ducting outside of the thermal envelope is insulated in accordance with Building Regulations.

The exhaust port of the unit must terminate to external air and be protected by a suitable wall or roof terminal.

Roof terminal to have a minimum equivalent free area of 10,000mm2.

Ensure unused spigots are capped off using the blanking caps provided.

2.4.1

2.4.2

2.4.3

2.4.4

2.4.5

2.4.6

2.4.7

2.4.8

2.4Ducting Guidelines

2.5 Electrical

WARNING: The appliance MUST be earthed. All wiring must conform to BS7671: IEE Wiring

Regulations.

WARNING: The CMEV. e / CMEV. eHT units must be isolated from the mains supply before

removing the fan motor assembly.

The installation must be carried out by a qualified Electrician.

When supplied from a 6 amp lighting circuit no local fuse is required. If electricity is not supplied via the lighting

circuit, a localised 3 amp fuse must be used (see wiring diagrams).

The CMEV.4e / CMEV.4eHT units are supplied with a pre-wired mains flexible cord – PVC sheathed, 5-core

green/yellow, blue, brown, black & grey & 0.75mm2.

‘If the supply cord is damaged, it must be replaced by a special cord/assembly available

from the manufacturer or its service agent. The replacement must be carried out by a

qualified Electrician in accordance with IEE or local regulations’.

Depending on required wiring (see diagrams), a triple-pole or a double-pole switch having a minimum contact

separation of 3.0mm must be used to provide isolation for the unit.

The recommended switches / sensors for use with either models are:

• For CMEV.4e, wire using either switch-live (lighting circuit) with/without external Greenwood Airvac sensor or via a

Greenwood Airvac GS2 2-position switch with an external Greenwood Airvac sensor (see below for function details).

• For CMEV.4eHT, wire using either switch-live (lighting circuit), via a Greenwood Airvac GS2 2-position switch

with/without an external Greenwood Airvac sensor or via a Greenwood Airvac GS1 3-position switch (see

below for function details).

(See Wiring Diagrams

on page 6).

The fan speed control must not be mounted above or closer than 1m to the cooker where

it could be affected by excessive heat or moisture.

2.5.1

2.5.2

2.5.3

2.5.4

2.5.5

2.5.6

2.5.7

2.5.8

5

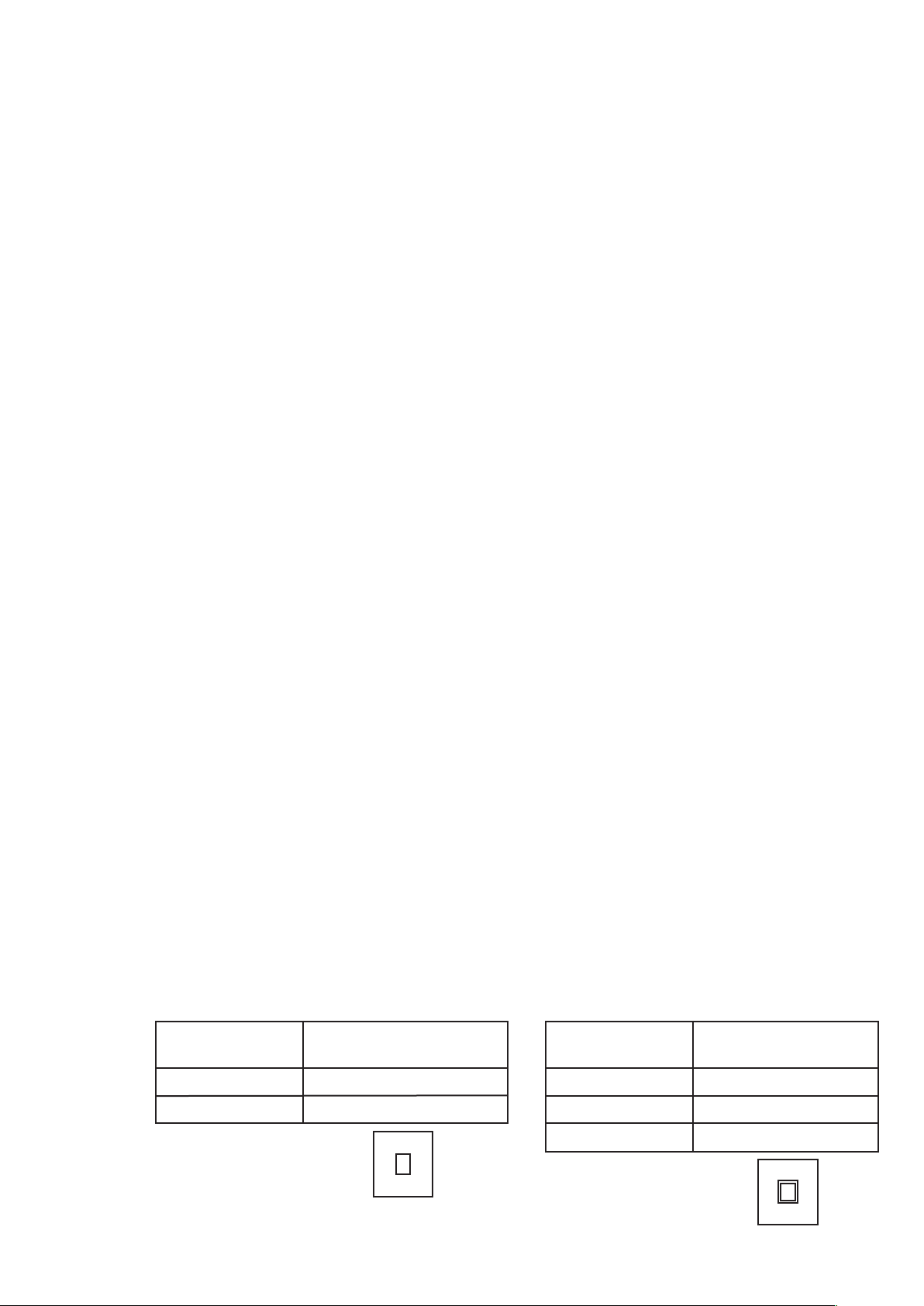

GS2 Remote Function

Switch Positions

Trickle (I) Fan running at trickle speed

Boost (II) Fan running at med/boost speed

II

I

II

I

GS1 Remote Function

Switch Positions

Trickle (Centre position) Fan running at trickle speed

Medium (I) Fan running at medium speed

Boost (II) Fan running at boost speed

CMEV. e / CMEV. eHT CMEV. eHT only